Researchers from the University of Southern California have developed yet another 3D printing process, which they call “Selective Separation Sintering”.

The new process is the product of USC Department of Industrial and Systems Engineering’s Jing Zhang, Behrokh Khoshnevis. Khoshnevis is noted as being the researcher behind the “Contour Crafting” concept for 3D printing large structures in concrete some years ago.

Although Contour Crafting really didn’t get very far, it did open up many minds to the idea of 3D printing buildings. Now Khoshnevis and Zhang have used their experience in the field to develop the incredibly straightforward Selective Separation Sintering.

But first, let me explain a bit about current methods of producing 3D printed metal objects, all of which are problematic in that they require complex equipment and are therefore expensive.

Two styles are typically used. One involves selectively flashing a powder bed with a powerful laser or electron beam to melt some of the metal powder, with repeated layers used to form the object. The other approach involves selectively depositing a binder into a powder bed, where the bound material is removed from the powder, placed in a furnace for sintering. However, the latter process requires polluting the powder with binder that becomes part of the final metal object.

Selective Separation Sintering changes all that, and I’m wondering why no one thought of this approach before because it seems so obvious in retrospect. Here’s how it works:

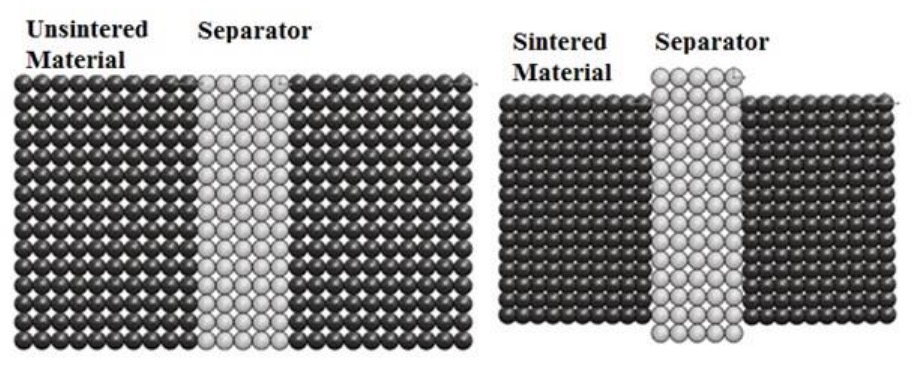

- There are TWO kinds of powder; one intended on becoming the final object, and the other having a much higher melting point than the first powder.

- There are two independent powder deposition mechanisms

- For each layer, the “object” powder is simply deposited, loose, in the intended position. The “not object” powder is deposited in all other areas.

- After all layers have been deposited, we have a cubic volume containing a mix of the two kinds of powder. The object is made of loose powder, but is held in the correct shape by the other powder.

- The powder-filled build chamber is transferred to a separate furnace, where the entire thing is heated up to the melting point of the object powder – but not to the non-object powder’s melting point.

- The object powder sinters into solid form.

- The final object is removed from the non-object powder, which remains loose (and can theoretically be re-used).

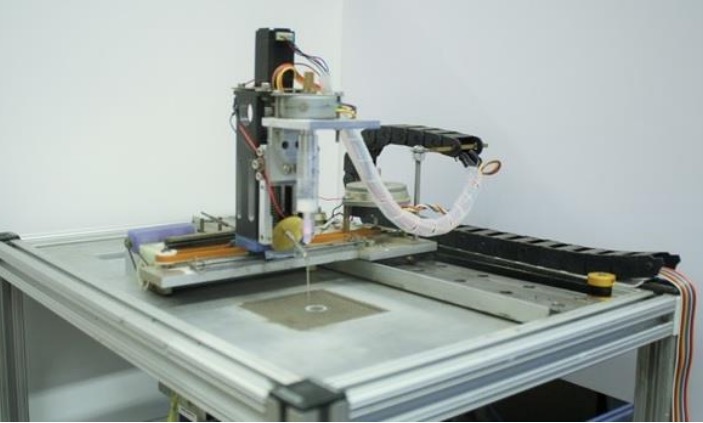

This process is spectacularly simpler than existing metal 3D printing processes, which require high-energy equipment, vacuum chambers, critical temperature management and other expensive compoenents. The “SSS” process simply requires two powder deposition units and a separate furnace. And this will work for ceramics as well as metal powders.

The simplicity of this approach could also permit use of the technology on the Moon and in space, where local materials could be sorted into the two powders for local production. In fact, NASA sponsored this particular research.

While many media reports indicate this process is destined for outer space, I suspect a much more practical – and profitable – application would be to launch a 3D printer that employs SSS. It would no doubt be far less expensive than current metal options, and potentially faster, too.

However, at this point the process is only a research project, with a prototype machine built that can produce objects. But it’s likely this will be scaled up into a real metal 3D printer by someone sooner or later.

Watch out, 3D metal printer companies!

Via UTexas (PDF)