A recent instructables proposes using “Milk” as a 3D scanning medium. I think this approach may be more trouble than it’s worth.

But first, how exactly does one 3D scan an object using “milk”? Actually, the process COULD use milk, but really it only requires an opaque fluid that visually contrasts with the color of the object being scanned.

Here’s what happens:

- You have the object immersed in a container containing the opaque fluid

- Your smartphone or other image capture device positioned above and aimed at the reservoir

- Fluid is set to drain from the reservoir at a consistent rate into a lower capture tank by gravity

- During the drain, the camera takes identically framed images at regular intervals

- The liquid level wraps the outer edge of the object as it lowers, which are imaged

- After the drain completes, the series of images is pushed through a script that interprets the changes in outline into a 3D model

This is a relatively straightforward process, but I believe it’s not one you might want to try for a number of reasons:

- Your object is going to get soaked. This may or may not be an issue, but if it is, it’s a big one. DO NOT SCAN PEOPLE THIS WAY!

- The fluid level may not lower consistently, leading to aberrations in the vertical axis of the 3D model

- Shapes with overhangs are just not going to work. This cuts out a lot of possible geometries, even if you orient them in the best possible way

- Shapes involving interior components are not going to work well either. Imagine something with struts holding components together – not going to work with this

- If you use actual milk for this, prepare for some cleaning or else expect a very foul odor from your workshop

- If you use dyed water as the fluid, you may corrupt the colors of your object

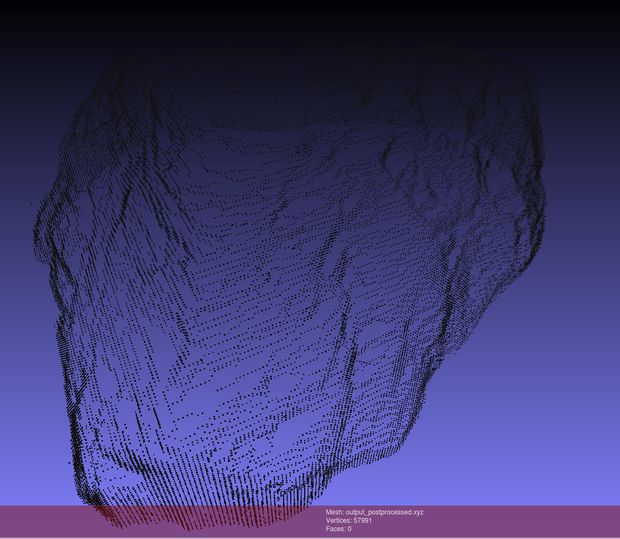

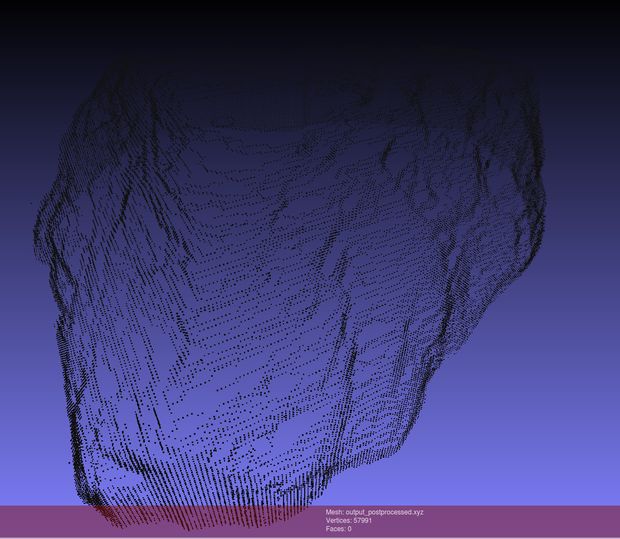

And there’s one final very good reason to not use this technique: there are many better and cheaper methods of 3D scanning available to you. For example, Autodesk offers multiple image-based 3D scan services for which you need only take a series of images and submit for processing – at no charge at all! Such services can produce incredibly good 3D models, and they’re often in color, too.

Keep the milk in the fridge.

Via Instructables