A small company in North Carolina has made big improvements on their 3D printer design.

The company made a name for itself with their previous machine, the F306, which was designed to address the needs of engineers and professionals. The F306 included several unique motion control features that made the machine more reliable and accurate, but it didn’t include a lot of bells and whistles.

The new machine, the F400, has all that and much more – and even a few bells and whistles.

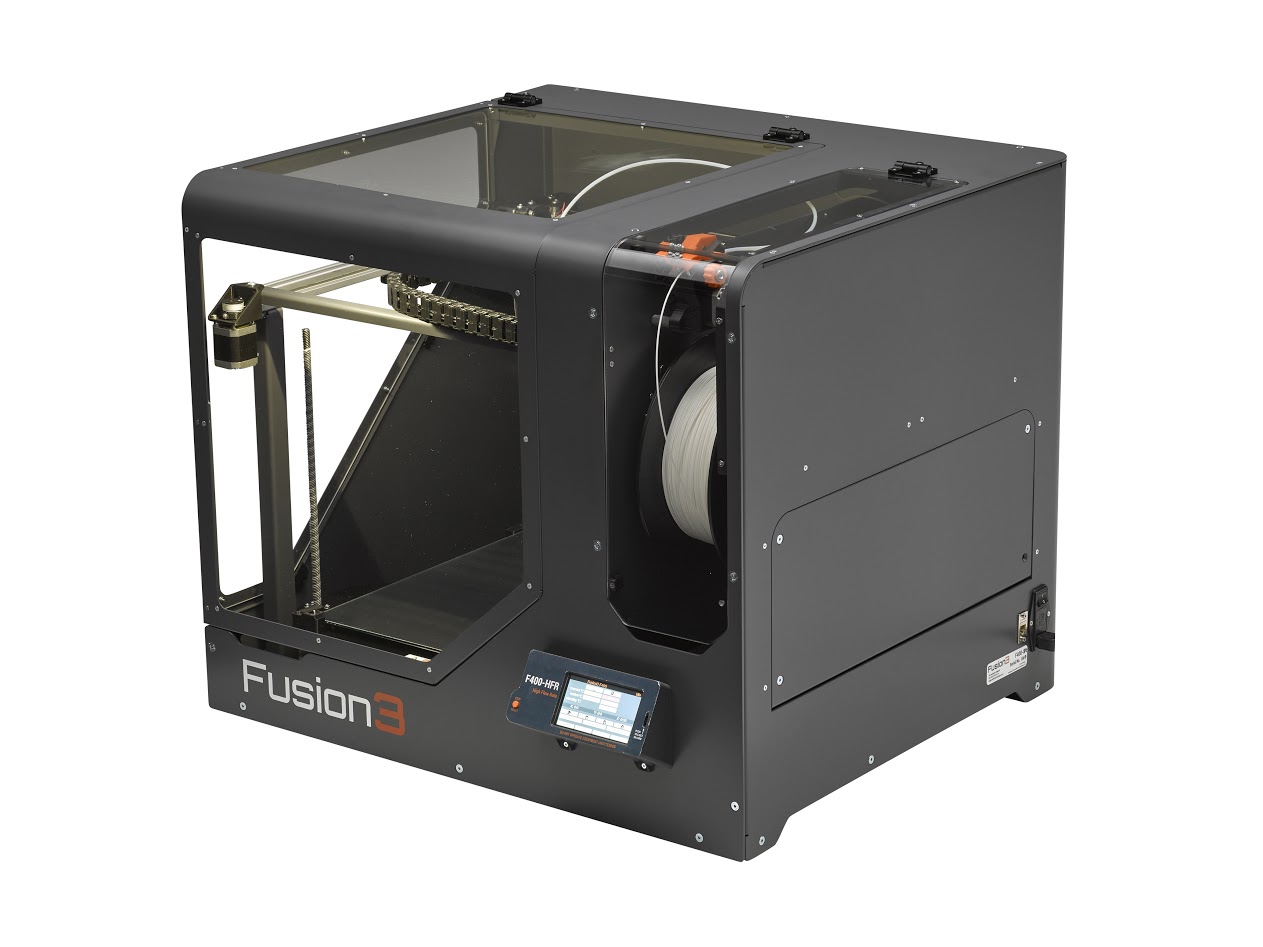

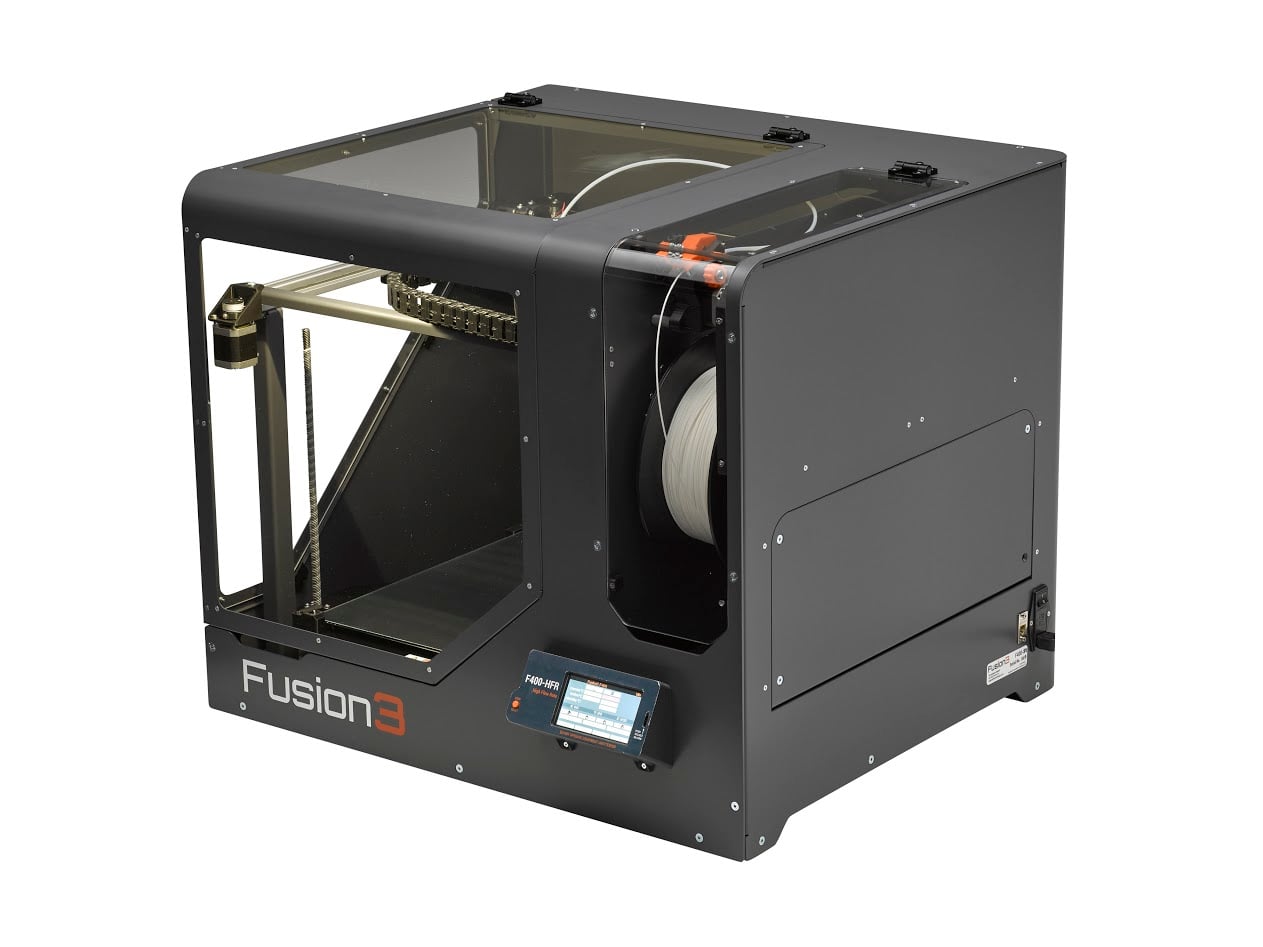

The major change appears to be the addition of a case to the product. Previously, the F306 had an open frame, permitting ambient air conditions to intrude on printing operations. The F400 changes that by including a completely enclosed case.

The enclosed case will dramatically increase print reliability and accuracy, as the environmental conditions can be stabilized. It also permits printing higher-temperature materials, such as nylon, ABS and polycarbonate, making the machine far more useful for professionals developing prototypes.

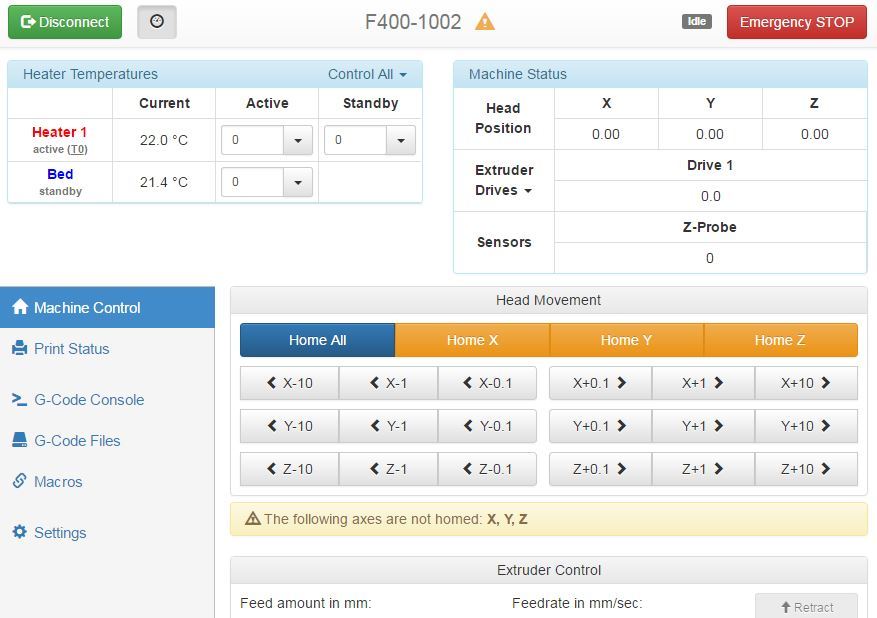

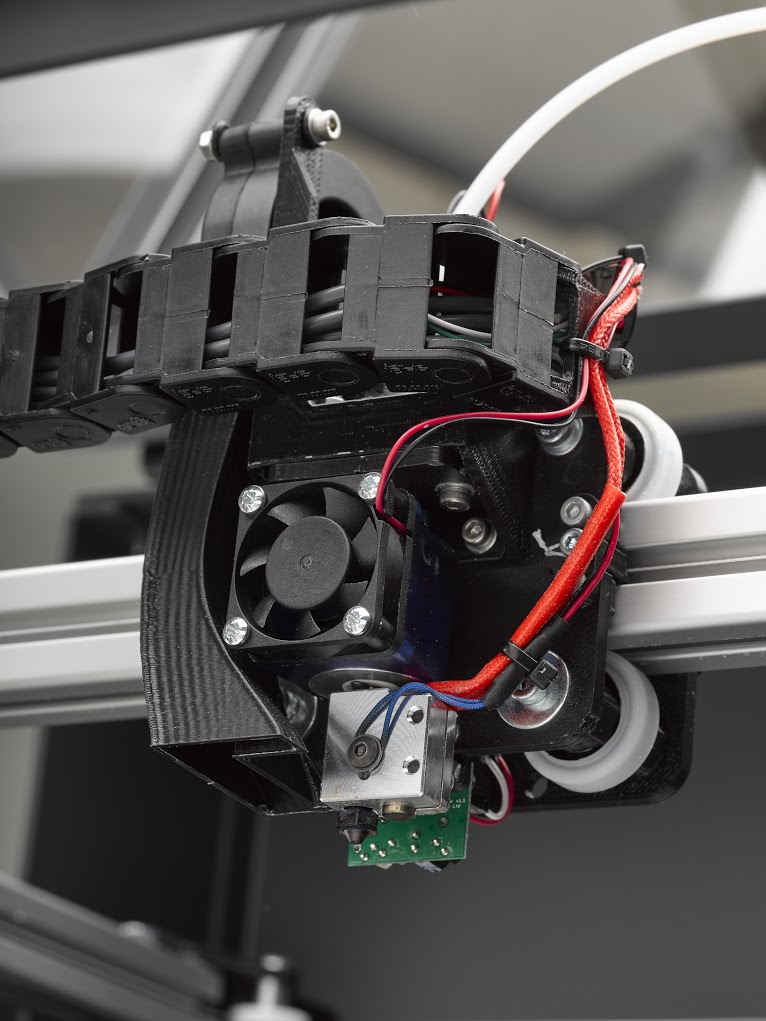

Another very important change in the F400 is its processing capability. A new 32-bit controller speeds up real-time motion calculations used to drive the extruder. This means the F400 can actually print faster – as much as 20% faster than the F306, according to Fusion3. In absolute terms, the machine can hit the very rapid rate of 250mm per second – and can do this in layers as small as 0.05mm for very finely resolved prints.

The print volume is quite healthy at 360 x 366 x 320mm, one of the largest you’ll find in a cartesian-style desktop unit. This is a substantial increase from the F306’s 305 x 305 x 305mm volume. The volume increase is actually quite suitable on this machine, because it’s enclosed chamber will now permit reliable printing of very large objects over long print durations.

And there are indeed some bells and whistles that everyone will appreciate:

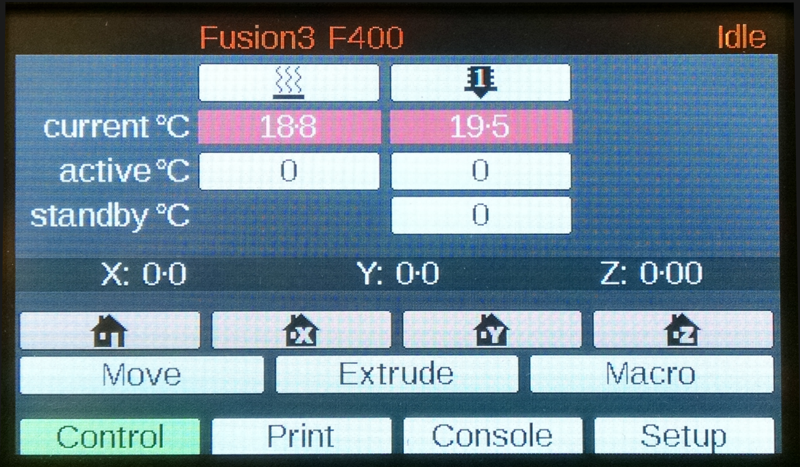

A large 4.7” color touch screen replaces the F306’s small LCD

A new integrated WiFi network permits remote operation

Automated calibration of bed level is done with an infrared sensor system

Simplified maintenance due to a more modular component design

The F400 comes bundled with Simply3D slicing and control software, the best pay-for slicing software option for 3D printers

Integrated E3D high-temperature steel hot end

Heat sensors automatically shutdown the machine if unfortunate events occur – a major safety feature.

Lifetime telephone support from the factory

Two year warranty! (This has to be the longest warranty I’ve seen from any desktop 3D printer manufacturer.)

And there’s one optional feature we recommend taking: an integrated HEPA/Carbon filter system that cleans the print chamber’s air of nasty emissions and odors.

There are two models of F400:

- For USD$4,499, the F400-S, which is the basic unit with all of the above.

- For USD$4,999, the F400-HFR (or “High Flow Rate”), designed for large, rapid 3D printing. The F500-HFR includes a special Volcano E3D print head and 0.8mm nozzle to achieve print speeds as much as twice as fast

Fusion3 is not addressing the hobbyist market by any means here, although the F400’s pricing might be within reach of some. No, instead they’re focusing on the professional market, where firms of all sizes may require very rapid prints of larger dimensions – at very low cost.

Consider a typical commercial alternative to the F400: Stratasys’ uPrint. This machine has a far smaller build volume, and costs perhaps 4-5 times as much. Plus, the F400 permits use of inexpensive generic filament as well, although I suspect F400 operators would likely use premium filament to ensure good quality results.

For Fusion3, the added features on the F400 open up many possibilities that may be required by their target market. It’s very likely they’ll gain many sales where buyers are evaluating between costly equipment and the F400.

Via Fusion3