Some interesting research in the journal Science and Technology of Advanced Materials shows how a 3D printed object could be functional in a chemical manner.

This story is a bit like the composite plastic filament products we’ve all seen recently, such as metal or wood filaments. In these products an alternate, non-printable material such as fine metal or wood particles are mixed in with a printable plastic like PLA and then extruded into a plastic filament. Objects printed with these composite filaments retain some level of functionality of the secondary material. Thus, you can “shine” a “metal” printed object, or drill into a “wood” object and so on.

This approach has been very popular, and, I might add, abused by adding seemingly strange materials like coconut, coffee or even algae to the plastic. However, these materials are static and offer only strength, weight and texture advantages.

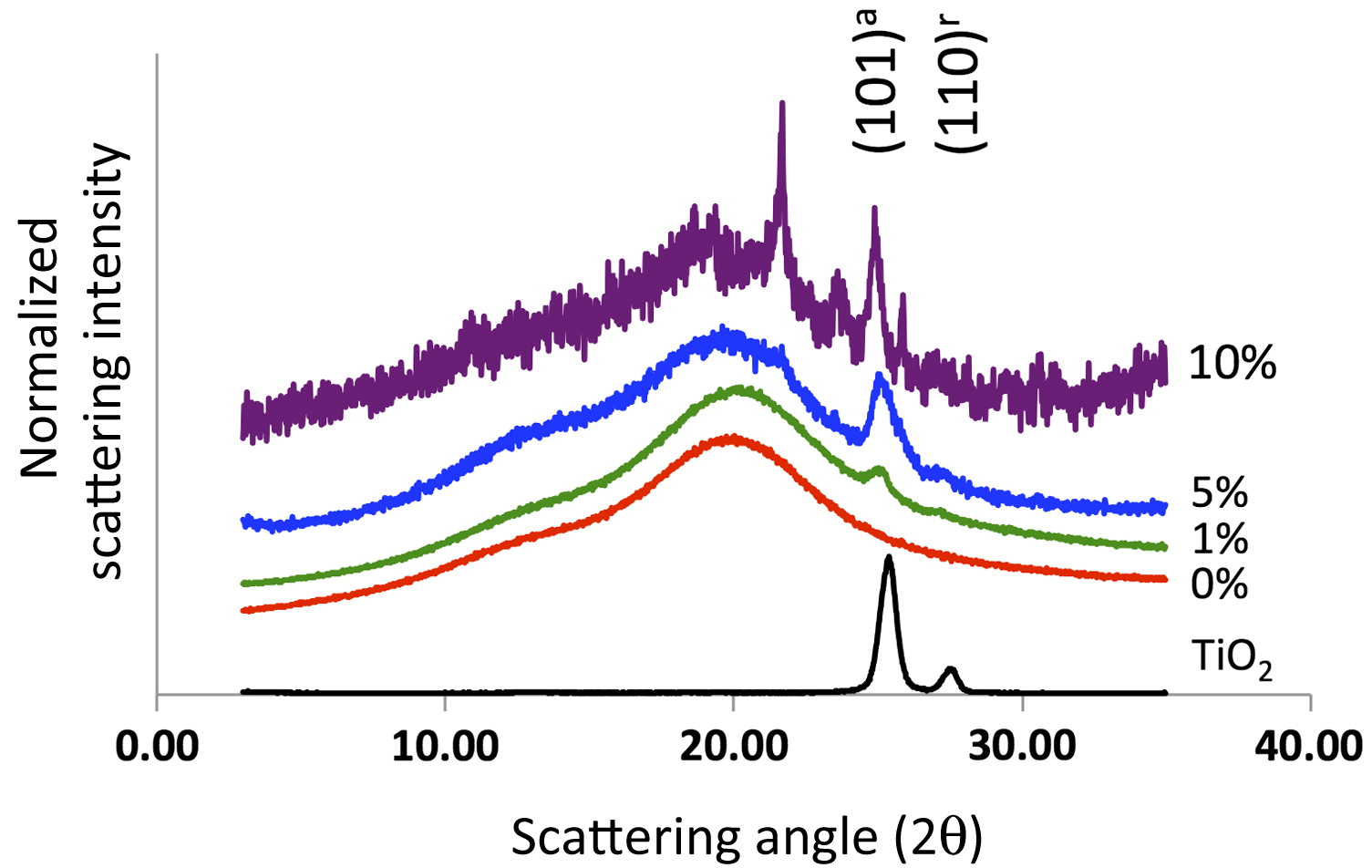

Now the new research goes a bit farther by proposing to mix in active chemicals to the printable plastic. In their experiment, the researchers combined titanium dioxide with ABS plastic to form a new kind of printable filament.

Then the fun starts. They explain in the paper:

Structures produced from the 5 and 10% nanocomposites display a higher breaking point stress than those printed from the pure polymer. TiO2 within the printed matrix was able to quench the intrinsic fluorescence of the polymer. TiO2 was also able to photocatalyze the degradation of a rhodamine 6G in solution. These experiments display chemical reactivity in nanocomposites that are printed using commercial 3D printers, and we expect that our methodology will help to inform others who seek to incorporate catalytic nanoparticles in 3D printed structures.

In other words, objects printed with the nano-material-infused composite can provide new functions. They say such functions could include: “catalysis, luminescence, thermal and electric conductivity, and gas storage, to name a few.”

All of these are potentially very powerful capabilities that could easily be incorporated into 3D prints to create objects that provide multiple and interesting functions. Imagine, for example, an air filter that captures a particular type of pollutant, or an object that helps transform one liquid into another.

This is precisely what the researchers did in their experiment. The titanium dioxide was able to photovolatically remove pollution from “air, water, and agricultural sources”.

Even better, the researchers say the process of manufacturing such composite filaments is not particularly expensive, so we may see the emergence of whole new classes of unusual 3D printing filaments for various chemical purposes.

Via TandF Online