A new filament from Avante demonstrates how much more advances in 3D printing filament chemistry can achieve.

The new FilaOne GRAY filament from Avante Technology is one of very few materials specifically designed for 3D printing engineering applications. Avante explains:

FilaOneTM GRAY provides very high flexural modulus, yet can bend and recover without crack- ing or crazing. The material is both tough and resilient, making it ideal for applications like drone landing gear, living hinges, toys and other parts that take a beating during use.

It achieves this by using a composite material involving carbon nanotubes. Here’s how it works:

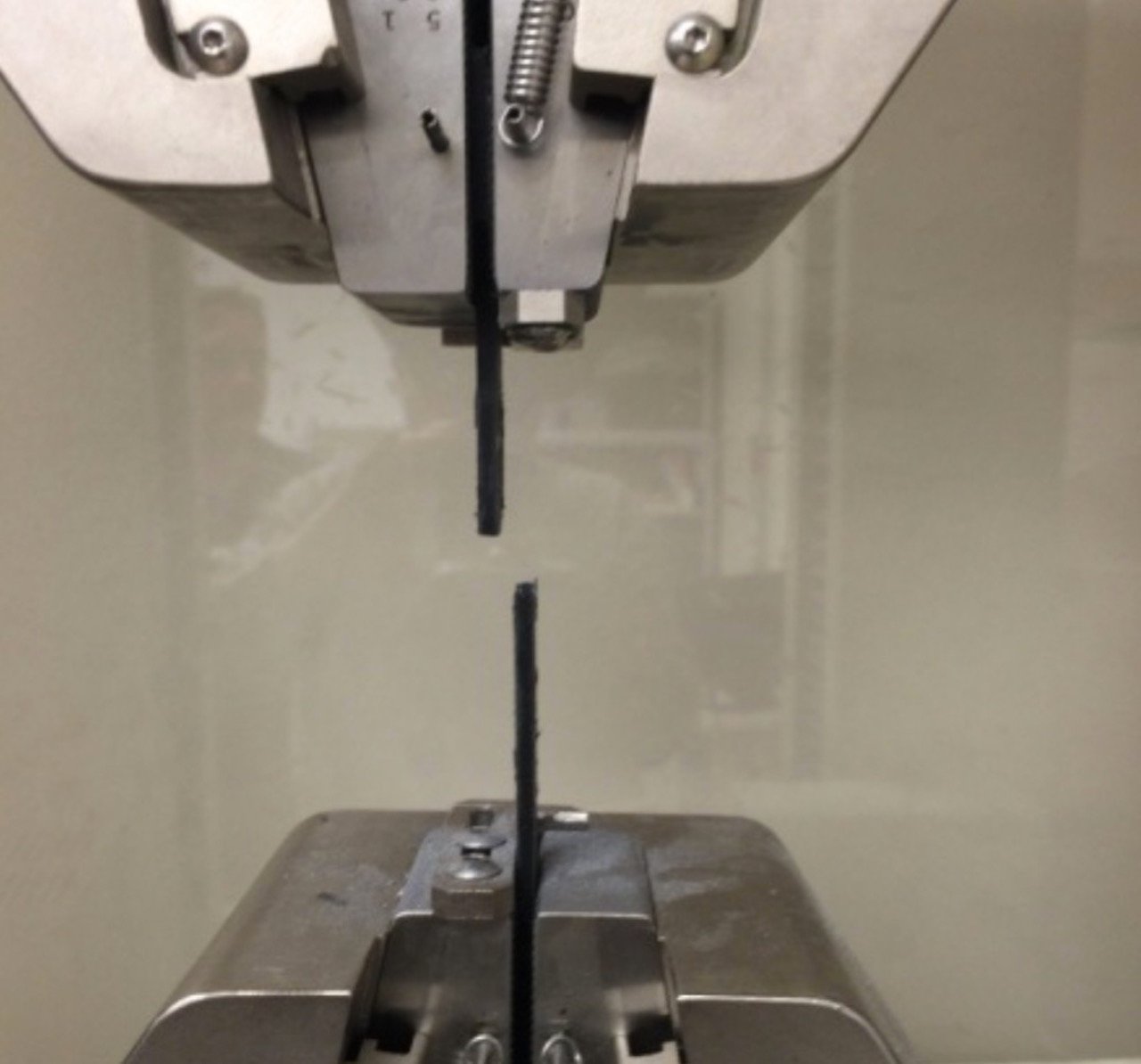

FilaOneTM GRAY contains a proprietary type of carbon nanotubes that have been highly dispersed throughout the filament to re-enforce the integrity of the material. These nanotubes provide strength and resilience to the composite. When other materials crack or break, FilaOneTM GRAY stretches and deforms.

Incredibly, this material provides a range of really interesting properties that I suspect would be just what many engineers are seeking:

- Mechanically strong: Significantly stronger than ABS

- Highly resiliant: Flexes and recovers without crazing or cracking

- Chemically resistant: Impervious to most common acids and caustic compounds

- Hydrophobic: No drying required before printing; printing unaffected by humidity

- Safe to handle: No chemically toxic out-gassing during printing

- Lighter: Much lighter than Nylon, ABS or Polycarbon- ate or PEEK, so 1 lb. provides 5% to 20% more filament by volume than these other materials

The chemical resistance is quite interesting. Here’s more details of what Avante Technology has been testing:

- Acids: dilute sulphuric acid, phosphoric acid, citric acid, boric acid, benzoic acid, acetic acid.

- Bases: caustic soda, potassium hydroxide, aqua ammonia, basic, acid and neutral salts.

- Solvents: acetone, ethyl alcohol, aniline, phenol.

- Gases: dilute chlorine, hydrogen sulfide, carbon dioxide, carbon monoxide, sulphur dioxide.

It’s chemical barriers like these that have likely stopped many engineers from using 3D printing technology in their applications. By removing them, we could expect more 3D printing usage, and corresponding increases in innovation.

I like to view developments such as this new filament as a kind of “second wave” of 3D printing materials. The first wave involved simply re-using existing filaments and plastics that were designed years ago for other purposes.

There’s been a weird “acceptance” of such non-optimal materials by the 3D printing community for many years, but the truth is that chemists can design many, many unique types of plastics for a wide variety of purposes. Now that’s beginning to change as the increased size of the 3D printing market has attracted a few chemical companies who can bring their research capabilities to bear on the problems in the 3D printing world.

Asante Technology seems to be in that second wave, as they are producing several very unique filaments that, while not for everyone, could offer very attractive properties to those doing engineering or industrial design.

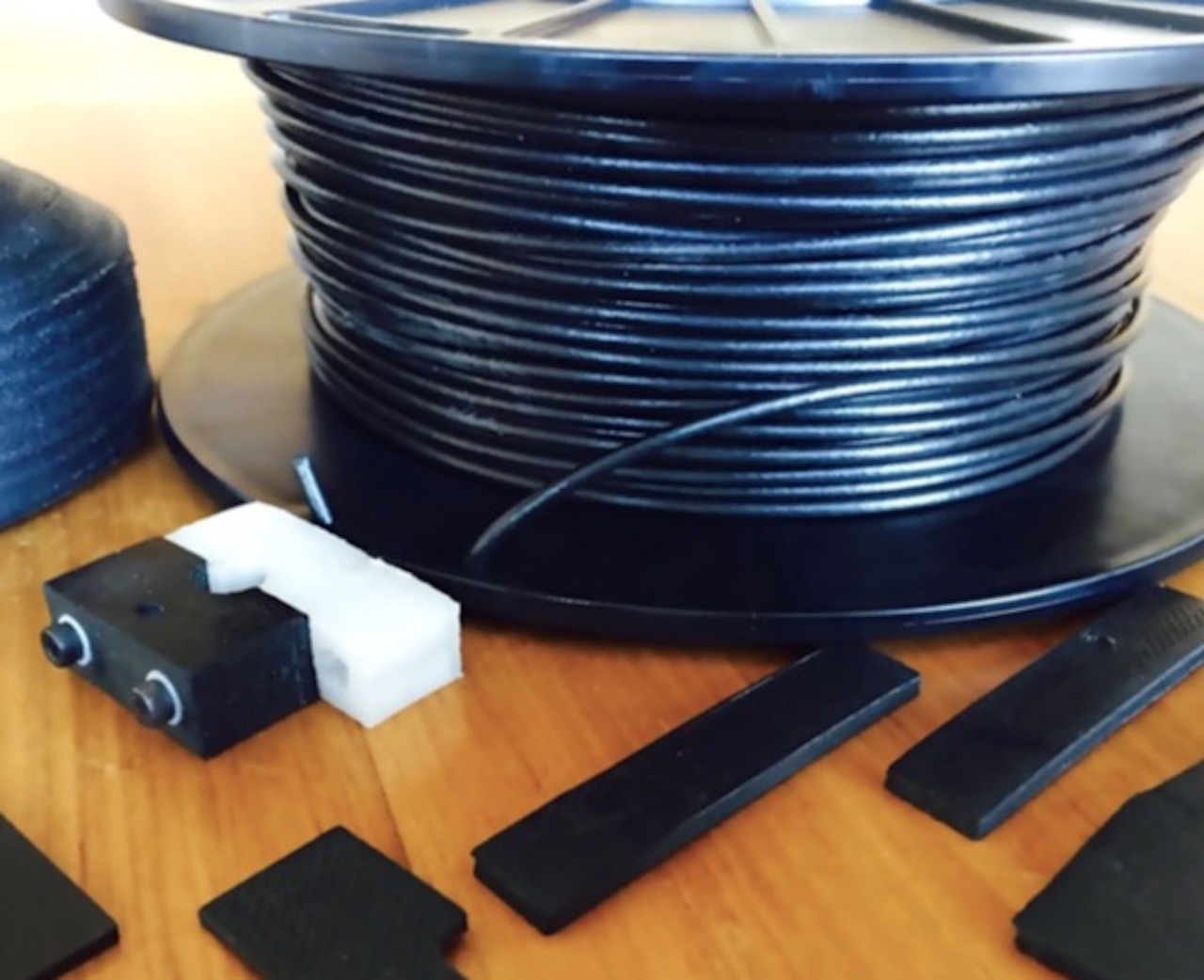

That all said, how much does the new filament cost? It is a bit pricey, but that’s what you should expect for a very powerful and specifically useful material. A 500g spool (in either 1.75 or 2.88mm formats) is priced at USD$199, but you’ll want to add USD$30 for the accompanying adhesion sheet for perfect sticking to your print surface. Avante Technology also appears to offer smaller sized sample spools for USD$25, which is where you might want to start experimenting with this interesting filament.