This article originates from Women In 3D Printing and is part of our effort to support the use of 3D printing technology by women. The article is re-published with permission.

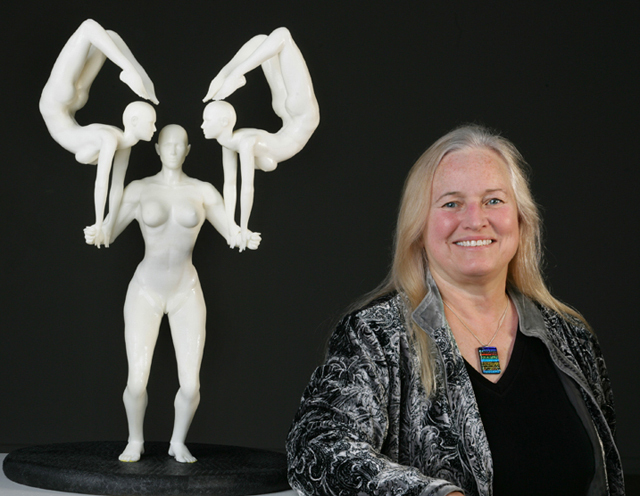

Prof. Mary Visser, Holder of the Herman Brown Chair teaches sculpture and 3D modeling at Southwestern University.

Her artwork has appeared in more than 130 exhibitions around the world including the touring e-Form Cybersculpture exhibition for the 2008 Olympic events in China. Visser received her MFA in sculpture from The Ohio State University and is Vice President of Ars Mathematica, an international organization devoted to promoting digital sculpture.

Nora Toure: Mary, could you let us know about your background and what brought you into 3D printing?

Mary Visser: I can remember making structures as a child in the piney woods of Georgia. I loved the sticky red clay and the thick forest of trees rising to the clear sky. My friends and I built many strange structures and dug tunnels through the clay earth. I would draw them and bully my playmates into building them, only leaving them at dark to go home. My mother has always had a strong influence on my life. She encouraged me to draw, sculpt and paint, buying my first art supplies. I guess she thought this would be better than digging up the earth and felling pine trees. She expected me to go to college, and so I attended OSU. I studied sculpture with the international sculptor David Black and Ceramics with many fine ceramic artists. I received my MFA in 1974. I spent all my time in the studio and it was heaven to work with so many different types of materials and processes, as well as, very fine artists.

My brother was a computer programmer and he gave me my basic understanding of binaries and the relationships between numbers and images. My first real art experience with digital systems was watching Charles Csuri create installations in Hopkins Hall using interactive sound that one could engage with to create visual movement. I found it fascinating, but my interests at that time were in developing sculptural forms that spoke to women’s issues. After graduating, I secured my present position at Southwestern University in Texas. I continued teaching and working as a ceramic sculptor creating abstract works based upon the figure.

What brought me to digital is I started working large scale with highly patterned polychrome ceramic figures in space. I needed some method of controlling how the color pattern moved over the forms and the negative placement in space between the forms. These figures were based upon body language that detailed these relationships between men and women as a choreographed dance in space on the walls of a large lobby. I scanned the walls and used the computer to design the negative spaces between the contours of the figures. I constructed these large figures from clay slabs with intense polychrome color patterns flowing over the outlines. Only the body language contours remained. I had a number of solo exhibitions and commissions for public and private spaces with this work. Upon seeing this work, I was asked by choreographers Mary Ganzon and Pat Stone to design a set and costumes for their dance “Within Rhythmic Kinship” performed in Austin at the Doughtery Arts Center in 1993 and 1994 at Texas State University in the Evans Theatre.

During this time, I became involved in Women and Their Work, Inc. after working with fellow artists Rita Starpattern and Laurel Butler on several large out-door sculpture installations. Our first sculpture installation was for the 5th Texas Sculpture Symposium. Later we did several installations at museums and sculpture parks across Texas. In my capacity as President of WTW we started a storefront art gallery for promoting the work of women artists, and to support the organization. This organization I am proud to say is still supporting women’s work across the state. I believe in activism to promote change and I became involved in developing Southwestern University’s first Women’s Studies program and served as its director for the first five years. This program is now known as Feminist Studies. I also sponsored the student organization, Women’s Voice, that spoke to women students’ issues. I taught the first Women in Art course at my university and developed the Jessie Daniel Ames lecture series devoted to women’s issues.

After five years of working on these projects, I stepped down to devote more time to my research and artwork. I had been designing forms using the computer that were very complex in their detail. The Circle of Life was my first large-scale 3D printed digital work. I was becoming frustrated because although previous works had been easy to make using hand building techniques in clay, this one was not. I made it in wax, but it could not be cast, as the intricacies of the form required a massive centrifuge. My experience with computers in designing my complex figurative works made me more fascinated with digital ideas and how one might produce such works based upon data. As an educator I knew the value of finding like minded people and started looking for others who were moving into this field. I attended the Small Computers in the Arts meetings and continued working with other artists in this group to promote digital sculpture ideas, first in Cyberspace and then finally in the physical work with 3D printing. I organized with Robert Smith the first digital lab at the International Sculpture Symposium held in Houston, Texas in 2001. I attended and participated in a number of conferences and symposiums on 3D printing over the years. But it was through ARS Mathematica of Paris, France, and Mr. Christian Lavigne that I made connections with sculptors around the world who were most serious about exploring this new medium. Mr. Lavigne and I are writing a comprehensive history on the development of digital sculpture and the pioneers who brought it too life to be published in 2016-17.

Nora Toure: So, what was your very first experience with 3D Printing?

Mary Visser: I had been working on a design in the computer called the Circle of life. I had envisioned 9 female forms diving into a cylindrical wheel of water with their hands extended creating an opening through which all life flowed. This work would replicate 9 sextants forming a full circle for the purposes of celestial navigation of life forces. I tried different materials to build it by hand, but at the scale I wanted, nothing worked. I wanted fine detail and tight precision. I had already been using the computer to design my forms for my large-scale ceramic murals and sculptural forms. I had been reading about selective laser sintering and discovered a company in Austin, by the name of Accelerated Technologies. They had a selective laser sintering 3D printer that could print my work as precisely as I needed to make a larger form from printed modules of its parts.

Nora Toure: What inspires you to create?

Mary Visser: You ask what inspires me to create; for me it’s a force that compels me to make what my mind can see so that I can share it with others. For example, the Circle of Life had been in the design stage for 2 years as each figure is composed of over 950,000 triangles. Each figure is very precise and includes all details such as fingernails, eyes, etc. I wanted very believable delicate female forms that were also machine-like with their precision as they would be responsible for all human life. I envisioned them as not only the makers of life, but also the ones who guide that life into existence and maturity to survive, like a sextant was for a navigator helping to guide the ship by using the sun and stars. I cannot wait to build my next design as I am compelled to see them come to life. I see the work of other artists, and like a worldwide conversation, I want to contribute to the dialog about art.

Nora Toure: Why using 3D printing for your creations?

Mary Visser: I came to 3D printing because I needed a precise method to create large scale sculptural forms made from multiple units. For example, the work, Reflections, is a mathematical formula whereby two reflected forms make one unit through their reflective relationship when connected to each other. The complexity of this form cannot be made using any other method. The Circle of Life was another work that was impossible to construct or cast using traditional materials. Its scale demanded materials that could be precisely manipulated to form one large circle. In stone it would have been rough and less real with a serious danger of breaking since the delicacy of the details were not possible in anything less than ivory. But one could not use ivory due to scale, let alone the legality of using such material. I constructed one unit in wax, but the foundry could not make a repeatable mold to cast nine of them due to the restrictions of the form. Also it would distort and be impossible to connect all 9 should we find some way to cast each one. To cast as one whole form without distortion would require a very large centrifuge to pull the molten metal down into the narrow constrictions of the mold. It was either too expensive or not possible with the present equipment. 3D Printing allowed me to make each unit very precisely with no need to cut off supports. I could join each one without any interruptions or seams. I could electroplate its surface and keep all detail. So I could have precision, fragile details, and multiple units to create a larger form using this process. I was free to envision my ideas and was no longer limited by a process regarding my designs. I could build as big as I liked using unit forms, or let’s say as big as I could afford at a more reasonable rate than by hand. But the computer is my hand, it is an extension of my mind like all other tools. The design and construction comes from my mind, my eye, and my hand. It is exactly what is in my mind’s eye.

Nora Toure: What do you think of the 3D Printing industry today? And how you like to see it evolve in the future?

Mary Visser: Twenty years ago, the thought of “bio-printing” human body parts seemed like the stuff of science fiction. Now it is being done on an ever-increasing scale, along with such things as using 3D printing to make artworks, musical instruments, and to replace parts of damaged coral reefs – a process that would normally take thousands of years. I believe that “3D printing technology holds answers we have not yet begun to explore; although the technology is simple in concept, it is evolutionary in what it offers. The idea that parents in a conversation with their child can print their child’s missing hand exactly to fit their idea of what that hand should be is to me most amazing.

In the spring of 2015 I organized Southwestern’s 37th annual Brown Symposium—“What Things May Come: 3D Printing in the Fine Arts and Sciences” and it was a great success. I focused the symposium on how 3D printing is changing the fields of sculpture, music and medicine. I brought in pioneers in each discipline to speak about these changes such as, Dr. Anthony Atala, who was the first person to 3D print a human kidney from human cells; Professor Olaf Diegel from Lund University, who uses 3D printing to make unusual and artistic musical instruments, and many digital sculptors from around the world like Bruce Beasley, Corinne Whitaker, Mary Neubauer, Robert Michael Smith and Christian Lavigne to talk about their use of 3D printing. I also asked Lisa Crump, co-founder of Stratasys, Inc., a high tech manufacturer of 3D printers used in the medical, electronic, consumer, education and aerospace industries to speak about the invention of fused deposition modeling for home 3D printing. You can review the videos of each presentation.

As a pioneer in this field of applying 3D printing to sculpture, my goal for this symposium was to show not only how 3D printing technology was in use now, but also how it would impact our lives in the future. I wanted to demonstrate how it is changing the way people think and approach creative solutions to all kinds of problems. I chose to focus on sculpture because it has the longest history with 3D technology and I included music because it has the shortest history with 3D printing, and finally regenerative medicine because “it had already begun creating the most astounding and remarkable solutions to health issues. Much of the hype surrounding 3D digital printing had up to that point been focused on rather mundane objects; not on the solutions or the creative thinking that was going on behind the object’s function. What I wanted to discuss was the printing of things we did not think were possible, such as functioning human organs from our own cells, or using it to simply see the past more clearly, or as engineers use it, to replace broken parts on the space station, or to make systems that can clean drinking water anywhere in the world. We should expand this problem solving ability and make it more available to all people. This is happening and as more people can make their own materials from the trash around the world this process will become a more sustainable production method.

I have my own personal wants with regard to this process. I want a flexible size laser-sintering machine that allows me to transform the build box to any size, one that allows me to choose the volume of material I deem necessary for support, and one that can use any type of material I desire including the ability to control the nuances of color and texture, without having to apply a surface color later. 3D printing is already a $2.6 billion a year industry and is projected to reach $6.5 billion by 2019. It will ebb and flow according to how the problem it must solve arises or becomes important.

*The Brown Symposium is funded through an endowment established by The Brown Foundation, Inc., of Houston. The first Brown Symposium was held in 1978.

Nora Toure: In your opinion, how could we encourage more women to become involved with 3D Printing?

Mary Visser: I think that is happening now by those of us who are purposely including them in exhibitions and symposiums. We as women must make it clear that this new field is creative, flexible and allows all persons to succeed. If you have an idea you can make it. I am an artist, who is not an engineer or a mathematician, but I can use this medium to see what a mathematical formula looks like in 3D space and it’s beautiful.

Nora Toure: What inspires you to help others [and especially other women] to enter in the tech. industry?

Mary Visser: My mother gave me my drive to learn and think creatively. She also said you will learn from those you help and they in turn will help you. My first introduction to feminist issues came from being held up as an example in a class for a required class project I had just completed. I was the only woman in the class and our instructor (male) said… “Look at what she’s done and she’s just a woman, what’s the matter with you men!” I thought about it for years because I had never before been told so explicitly that a woman was not capable. I thank my mother, my sisters, and my brothers for never letting me know that attitude was out there. I make sure my students know (both women and men), that they can work toward solutions without prejudice. That passion comes from finding the solution and that beauty is in the simplicity and effectiveness of the idea.

Nora Toure: Do you think we have made progress in having more women to join

tech. industries?

Mary Visser: I think we have made inroads with the focus on developing math skills in young girls and programs that promote engineering to young girls and women. But I would like to rephrase the question. Do you think tech companies have made progress in learning how creative women think about, design, and solve problems, using them to their best advantage? Perhaps that should be our next step to getting more women in all fields. Our educational systems should promote connections across disciplines and the idea that solutions can work across many fields. We should promote complete circle thinking and by that I mean what are the advantages and disadvantages of this solution to the problem, is this the only problem it will work on? I do believe that we can do more by having companies and schools promote creative thinking across disciplines.

You can follow Mary through her website.

And don’t forget to join the Women in 3D Printing group on LinkedIn and Facebook