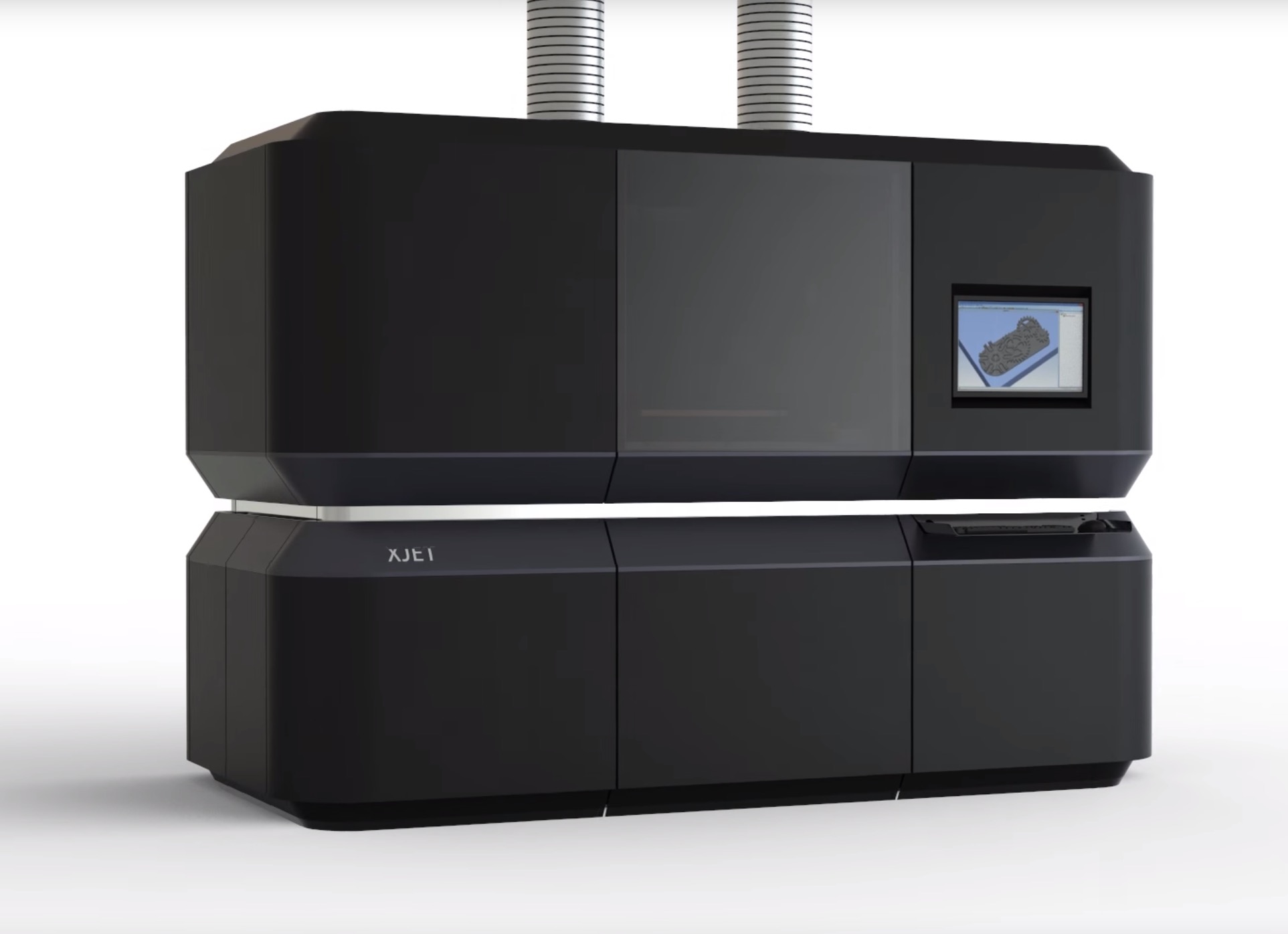

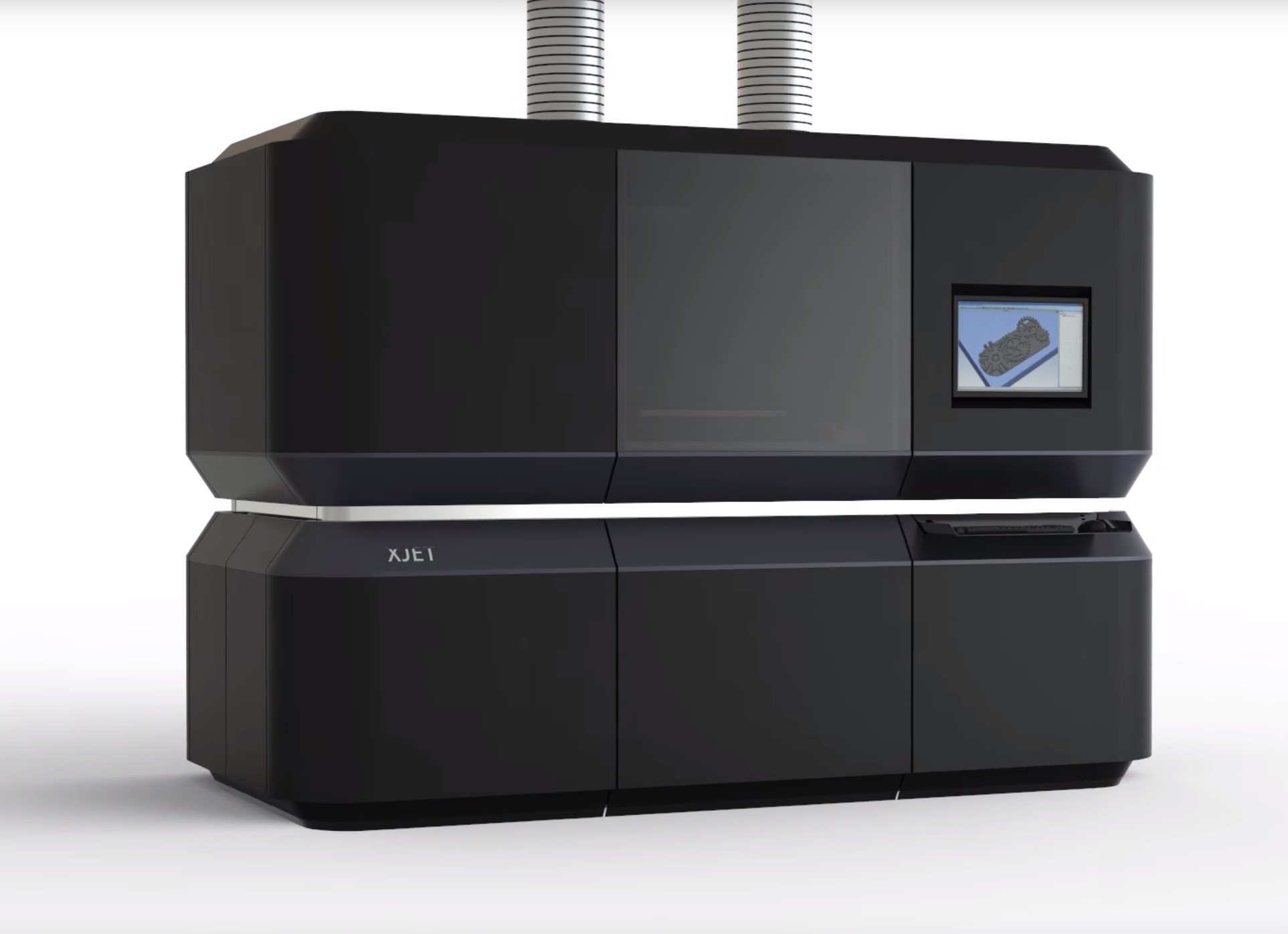

Israel-based XJET announced a huge USD$25M investment to bolster their progress in developing an incredibly innovative metal 3D printer.

XJET’s approach is quite unique, and perhaps could become the leading approach to metal 3D printing due to the several advantages of the process.

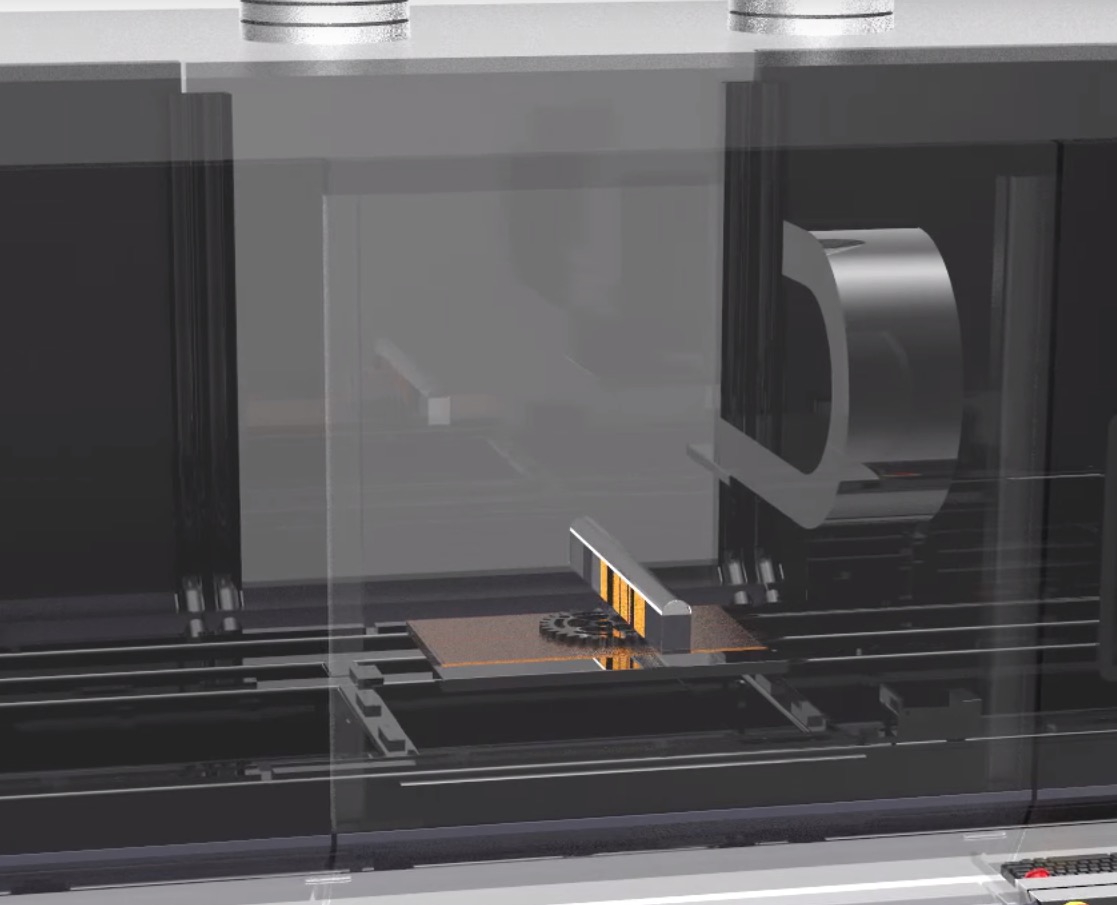

Like most metal 3D printing processes, XJET also uses fine metal particles. But unlike other approaches, XJET does not use a powder bed that’s selectively fused. No, their process is much more like a standard 2D inkjet printer.

Their secret is to place the nano-sized metal particles in a liquid solution. The solution is then jetted through inkjet-like heads – with corresponding density – onto layers of a print. The temperature within the build chamber is kept at a very high level, around 300C, which causes the solution to instantly evaporate and the nano-particles of metal to melt and fuse into the print layer.

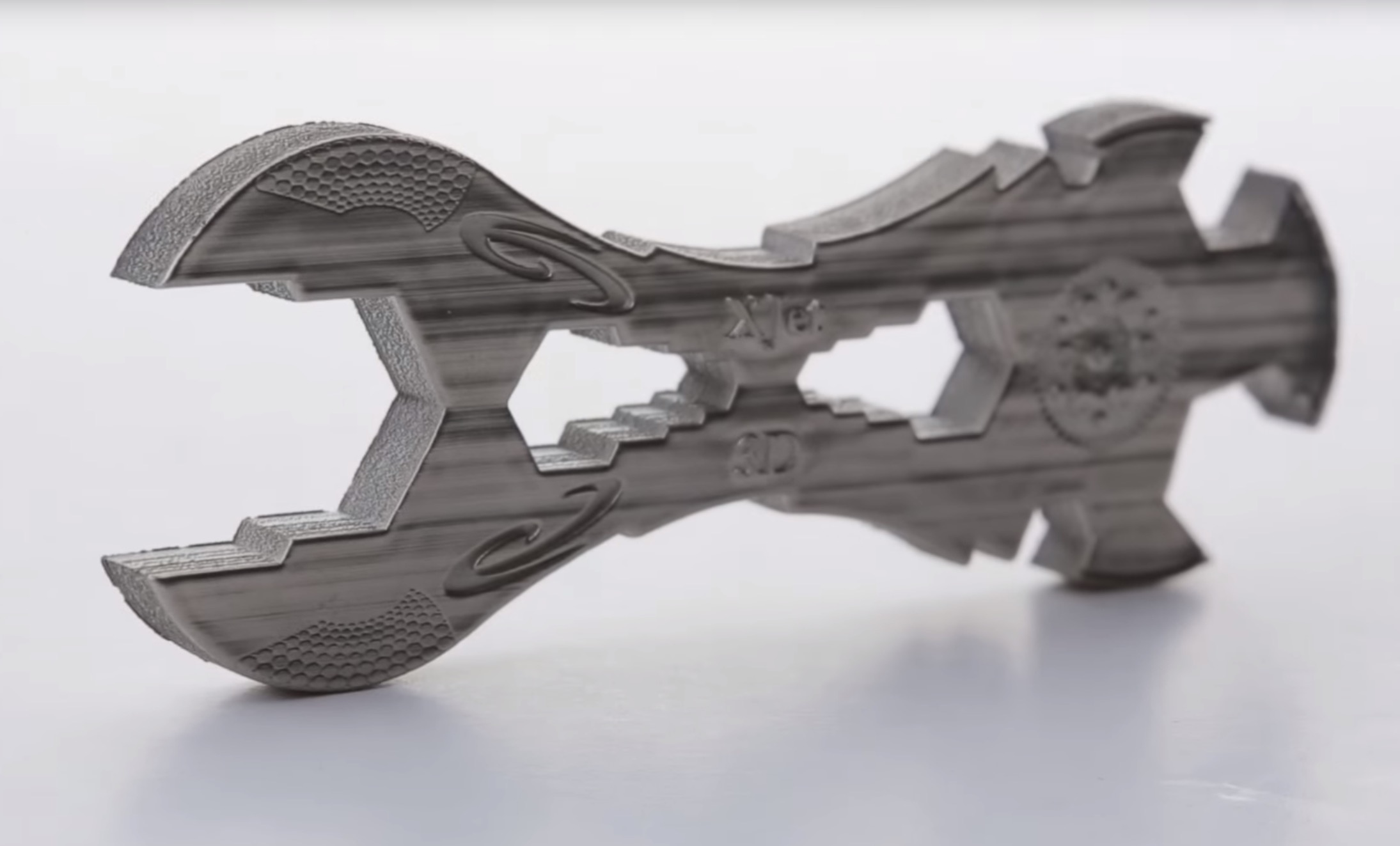

Using this approach they can achieve astounding levels of print detail, similar to what Stratasys’ PolyJet technology can achieve – except in metal! Essentially, they’ve found a way to use the highly dense inkjet deposition method with metal. Meanwhile, the other metal 3D printers are limited by the size of their lasers or electron beams for accuracy.

XJET’s approach should also be quite a bit faster to produce metal objects, as the inkjet can travel quite fast without concern over melting, as that happens automatically within the heated chamber. This video shows how it works:

There are other significant advantages, one being safety. In other approaches, loose metal powder can become airborne and thus toxic metals could be inhaled by nearby people, or become an explosion hazard. As a result, most metal powder-bed machines require sealed build chambers that significantly add to costs.

However, XJET’s liquid approach does away with all that. There are no airborne metal particles, as they are safely contained in a liquid solution. This also makes material loading far easier: just plug in a cartridge. This also could provide XJET with a reliable revenue stream as it may be difficult for others to provide appropriate material cartridges.

The prints emerging from the XJET machines require little post processing, aside from removal of support material; they are said to be metallurgically identical to conventionally produced metal objects.

XJET is actually not a new company. It’s been around since 2005, and originally focused on the solar industry. However, it seems that they realized their technology could be applied in other ways and they’ve done a pivot into 3D printer manufacturing.

That’s good news for buyers of metal 3D printing, which just happens to be the hottest market for 3D printing recently. Now the USD$25M investment, which by the way includes the participation of Autodesk, will enable them to grow much faster.

Watch for XJET to get big very quickly.