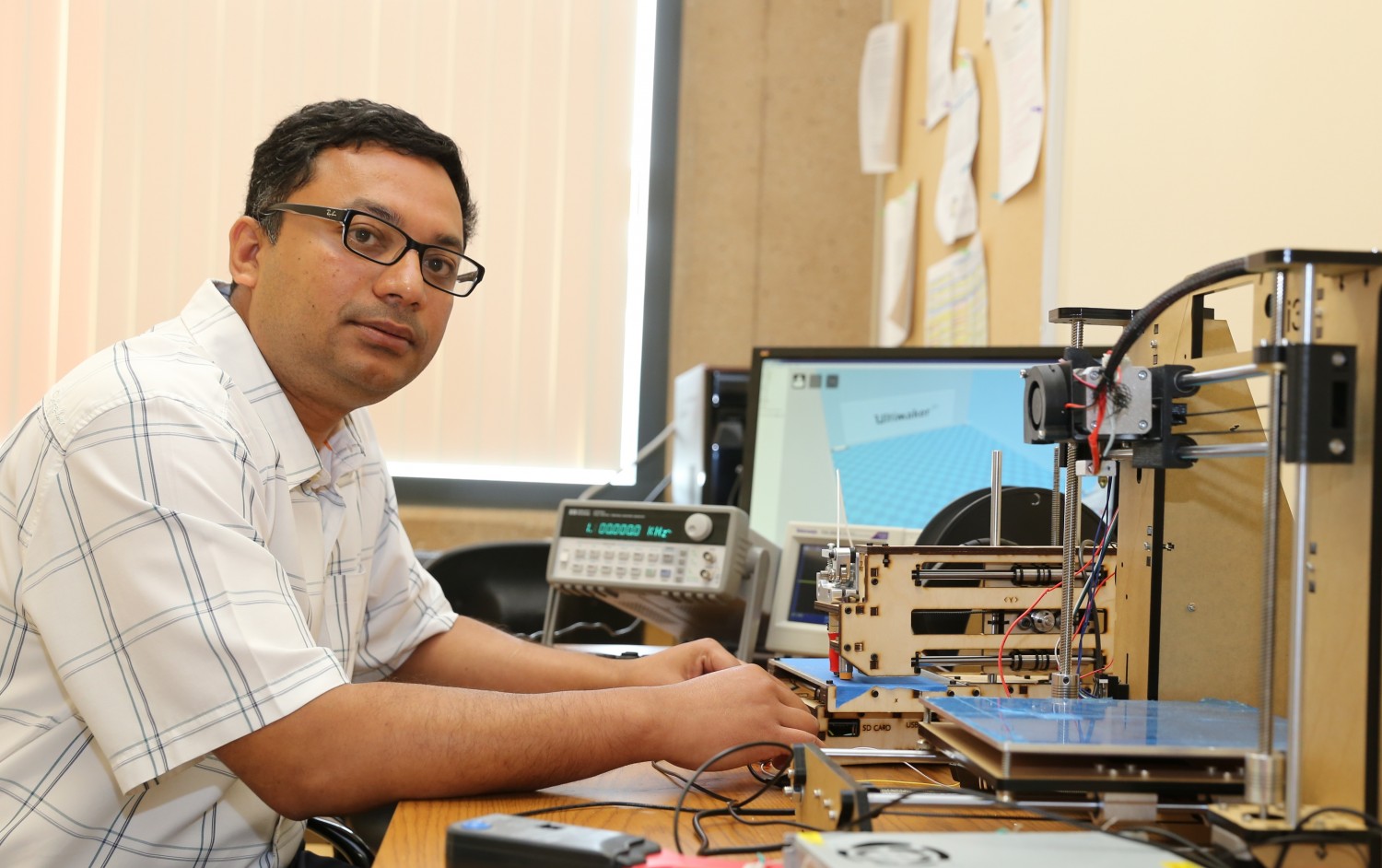

Researchers at the University of California at Irvine have found a potential security issue with 3D printers, but I believe fears expressed are overreactions.

What’s all the fuss about? The UCI researchers realized that they could merely listen to a 3D printer to digitally capture the object being printed.

How does this work, exactly? For extrusion-based 3D printers, the sound emitted by the three stepper motors moving the extruder are, as you might expect, precisely matching the XYZ movements. By listening to these sounds, and separating them into X, Y and Z axes, it might be possible to transform these into a 3D digital shape.

However, I see a ton of issues in actually doing this.

First, the sounds may not properly capture the extruder motor, so that while the movements of the extruder might be captured, it’s not necessarily known when the extruder is pushing plastic. Depending on the geometry of the shape, the “movement envelope” might be substantially different from the actual object.

Another problem is time. Most theft-worthy objects would presumably be complex and larger, making the requirement for consistent audio capture be significant. The UCI report suggests dealing with stray smartphones that might be used to surreptitiously capture sound, but what worker would stand beside a running 3D printer in exactly the same place for the hours required to complete a print? You’d have to plant a fixed microphone nearby to truly accomplish this.

Simple objects, such as the “key” shape used in the UCI experiment might be captured, but the trick there is likely that the shape is simple. A vase shape, for example, involves few starts and stops, while a more complex shape might have tens of thousands of very rapid starts and stops, making reliability of this process very suspect. In fact, since the audio shape capture method is serial, that is the shape depends on the ENTIRE capture, losing one portion could fail the capture.

Multiple extruder prints would also be more complex to capture, as the audio would have to distinguish between two different extruder movements.

In my experience, all 3D printers have different audio qualities. My original MakerBot CupCake, for example, was ridiculously loud, while more current models are extremely quiet, especially those with enclosed build chambers.

Thus, I believe the fears stated by many on this effect are totally overblown. This is very likely not a practical method that could be used with any reliability or guarantee of quality.

Via UCI