Back in 2014 I wrote on the REVOcaster, a rotational casting device that could complement any 3D printer operation. Now it’s available for order.

Rotational casting is a manufacturing method that’s different from 3D printing, yet could be quite complementary in some situations. Here’s how it works:

- A mold is created (possibly by 3D printing)

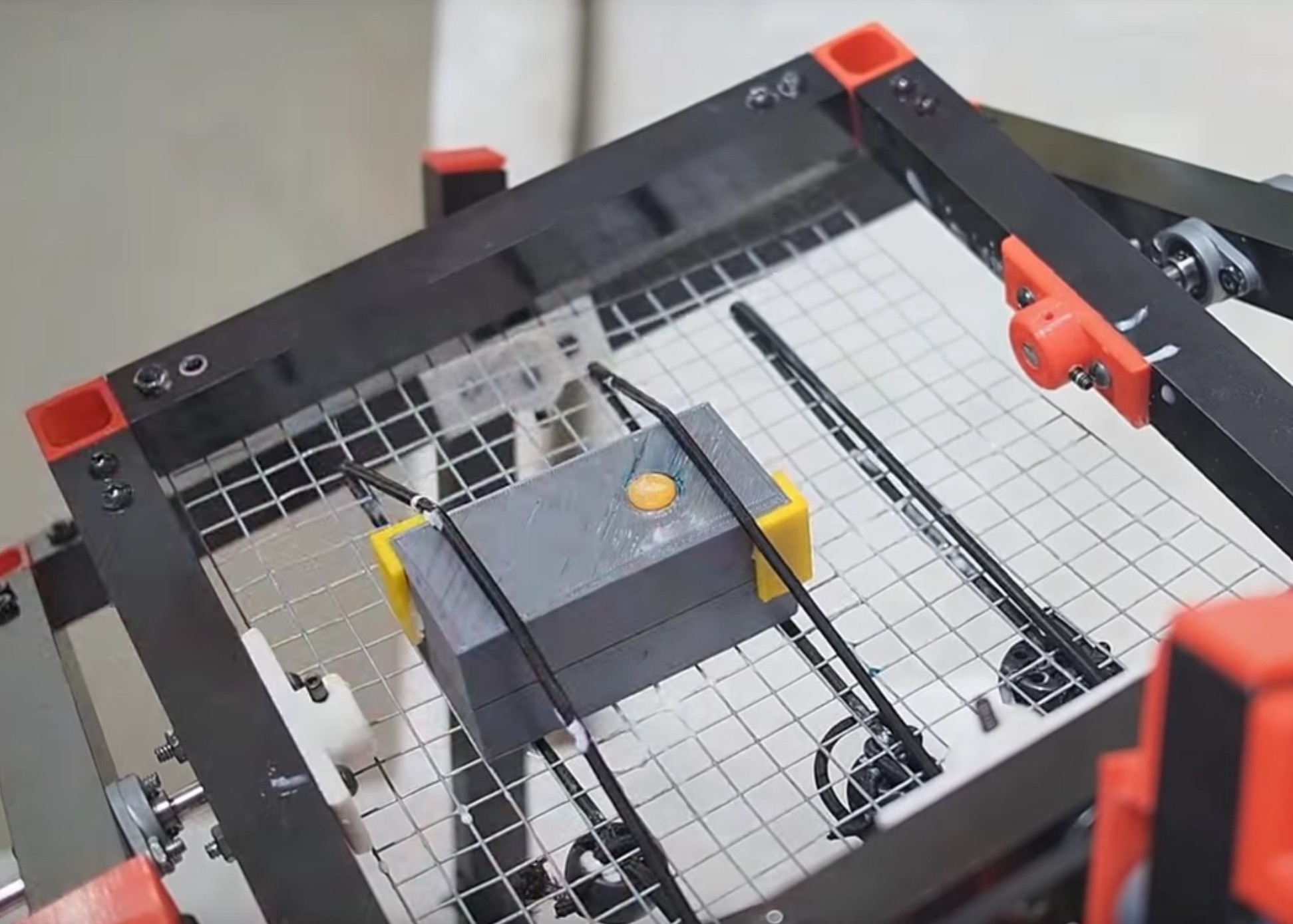

- The mold is mounted in the REVOcaster

- A quantity of liquid casting material is injected into the mold – but not an amount sufficient to fill the mold

- The REVOcaster rotates crazily in all directions

- Centripetal forces drive the liquid casting material to the edges of the mold

- The liquid solidifies, creating a hollow part!

Watch the video to check out the rotational action:

Why would you want to use this technique? It’s only applicable in the following situation: you need to produce many identical copies of a part whose geometry is suitable for casting. (Suitable means it has no overhangs or other structures that would permanently “catch” on part of the mold.)

This process could be spectacularly faster than 3D printing each part on its own, if your situation matches.

While you could obtain benefit with conventional casting, there is an advantage from using rotational casting with the REVOcaster: hollow parts require far less casting material. They may also cure faster, due to less material involved.

The REVOcaster is a small desktop rotational casting unit that can do exactly this. MagicMaker, the Calgary-based company behind the REVOcaster provides an example to contrast the two styles of making a quantity of a 1-hour printable model.

- In six hours, a 3D printer will produce exactly six parts.

- In six hours, the REVOcaster would produce 24 parts – including the time required to 3D print the mold. If producing more than 24 parts, it just gets better.

There’s more. When you are casting, you have complete control over the material. You can use a wide variety of casting materials, such as silicone, epoxies, or even food substances such as chocolate. Just be careful the mold is made from non-toxic, food safe materials.

You can also mix other elements into the liquid casting material, like metal bits to provide a metallic shine, dyes to provide colors or, in the case of chocolate, nuts!

The REVOcaster is now available for pre-order on Indiegogo at an initial price of USD$500, which of course will rise as more units are sold. They’re expecting to ship the first units late in 2016.

One word of caution: this is a project from a small startup company and as we’ve seen in the past, some ventures don’t work out. Always be careful when ordering from such operations and be aware bad things could happen.

Via Indiegogo