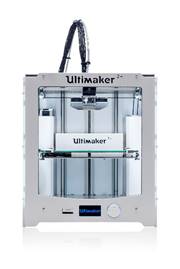

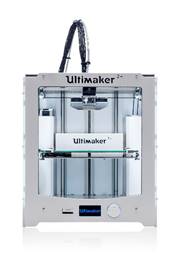

We’ve been waiting for Ultimaker to announce something new in their hardware line and this is it.

Today they’ve announced the Ultimaker 2+ and Ultimaker 2 Extended+. To be sure, they are modifications of the highly successful existing line (which we reviewed in detail here) and not entirely new machines. Build on success is the mantra here, so it seems.

There are three new and highly useful features, some of which we’ve seen hints at in the past:

Interchangeable Nozzles: This feature enables you to quickly swap the nozzle for one of a different diameter. For very detailed prints, you may wish to swap in a nozzle with a smaller than normal (0.4mm) hole, such as a 0.2mm nozzle. For higher-speed larger, coarse 3D prints, you might want to use a 0.8mm nozzle. This method was pioneered by the Ultimaker community in the “Olsson Blcok” add-on kit. Now it’s officially part of the machine.

Optimized Print Results: Essentially this feature seems to be a more robust extrusion mechanism. Ultimaker describes it as:

With the inclusion of a more powerful geared feeder, printing materials are less likely to skip.

We’re quite interested in this feature, as it would help with one issue we found when testing the previous model: sensitivity to less-than-optimal plastic filaments.

Enhanced Surface Quality: We’re not entirely sure how they achieve this, but we suspect they’ve beefed up the post-extrusion cooling system to more rapidly cool extruded plastic. This would reduce slumping as hot plastic would have less time to dribble around.

As of this writing we’re not certain of any price changes for the new machines over the older models, but we suspect it will be approximately the same.

Via Ultimaker