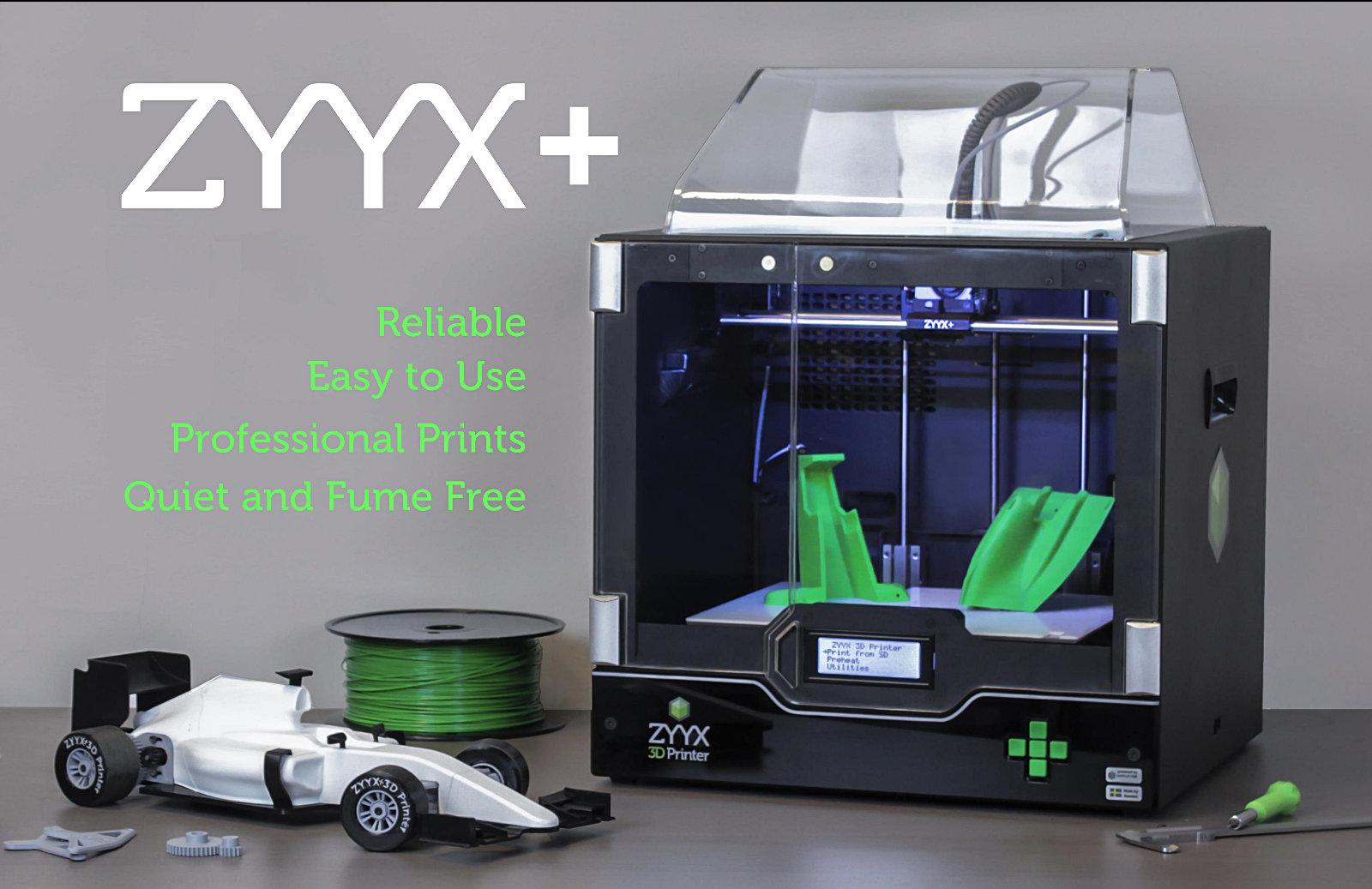

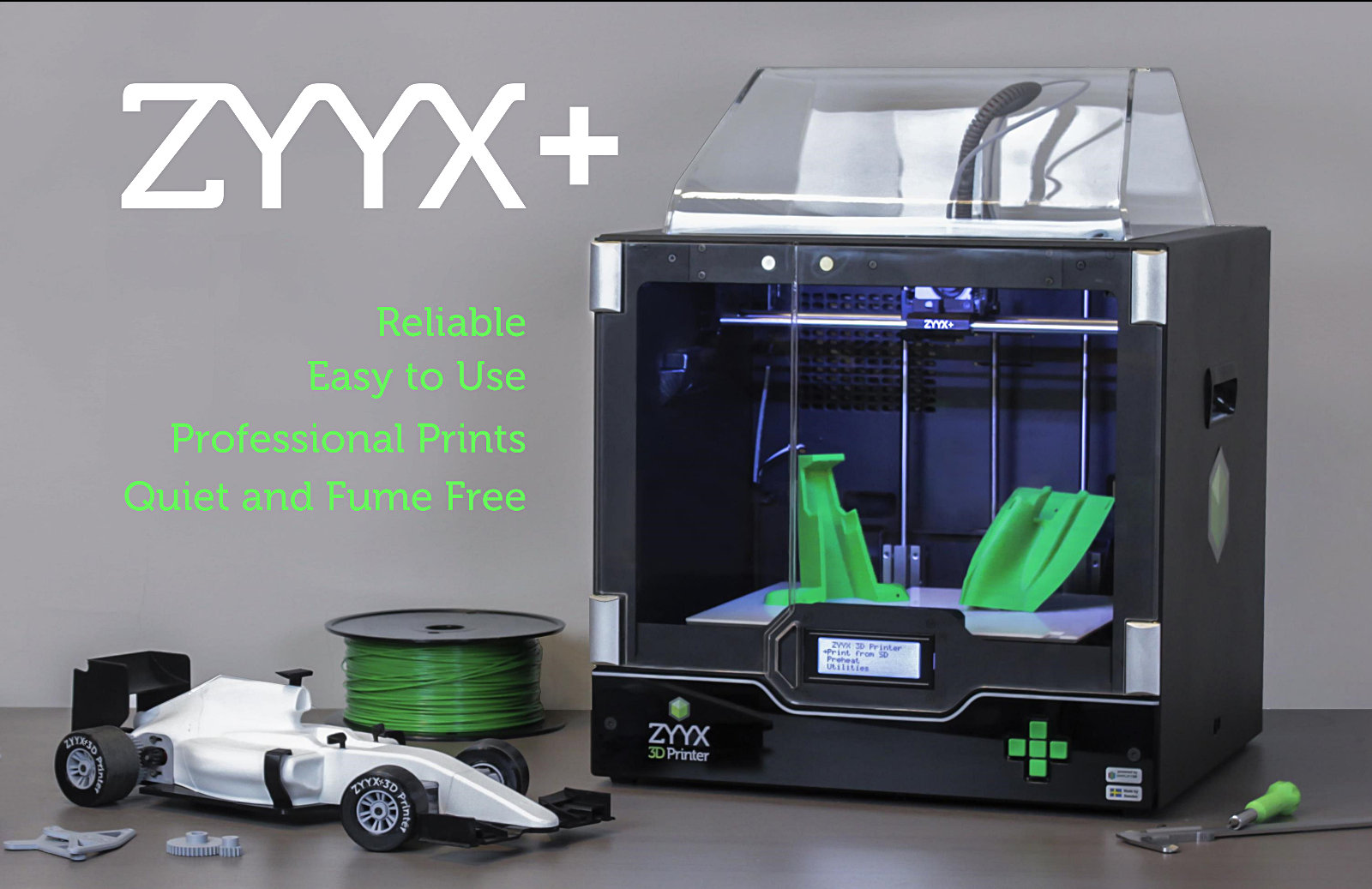

Magicfirm announced a new 3D printer model, the ZYYX+, which seems to focus on new features that you will definitely appreciate.

The company’s prior model, the ZYYX, was an interesting device that included several important ease of use features such as auto-leveling, closed build chamber, filament monitoring, failed print detection and our favorite feature, an integrated fume filter, making the device safe for use.

All those features persist in the new ZYYX+, but it appears the company is refining the device in what you might call minor technical ways, but in fact we believe these to be critically important improvements.

What’s changed? First, the ZYYX+ now has solid aluminum used for all moving parts of the print head. This should increase print quality and accuracy by reducing wobbles.

They’ve developed a new style of cooling fan, which is not only has increased power to more reliably cool the top of the hot end, but they’ve also relocated the fan to provide a much easier maintenance procedure on the extruder.

Here you can see how easy this is: just tip the fan to the side and you have full access to the internals of the extruder to clean out any accumulated debris.

The company has fine-tuned their movement software to better handle tricky situations such as vibrations introduced by repeated quick movements, and retractions, which are often trouble on other machines.

The company also announced the availability of specially designed plastic filaments for use in the ZYYX+: ProABS, ProPLA and ProFLEX. While these filaments are not required for the ZYYX, the machine and its software profiles are tuned specifically for them. In other words, you’re likely to get better prints if you use their materials.

What’s important to us is the theme behind these changes. They are not “flashy” specifications that one might introduce to attract buyers. No, these are mostly invisible internal changes that just make the machine better. These are things one would do to improve 3D printing performance after careful observation of machine operation.

This is what we want to see in every 3D printer vendor. Make the machine better, make the machine more reliable. Add bells and whistles later.

Via ZYYX