SmarTech published five predictions for the future of 3D metal printing and we thought we’d take a closer look at them.

The company provides 3D print industry analytic reports, primarily for investors and manufacturers at premium prices, but we see some of their material, too. Recently they published the following predictions for their view of the metal 3D printing dimension:

1. Metal Additive Manufacturing Will Become the Focus of Major 3D Players

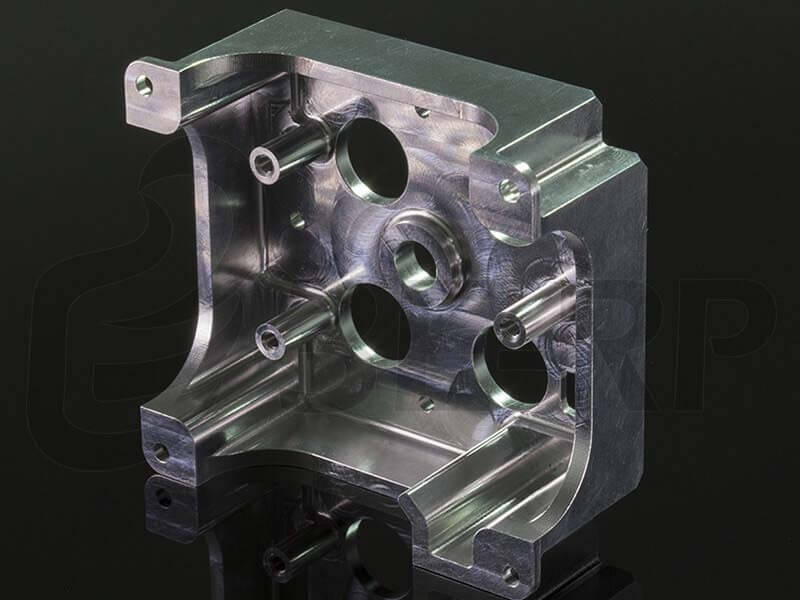

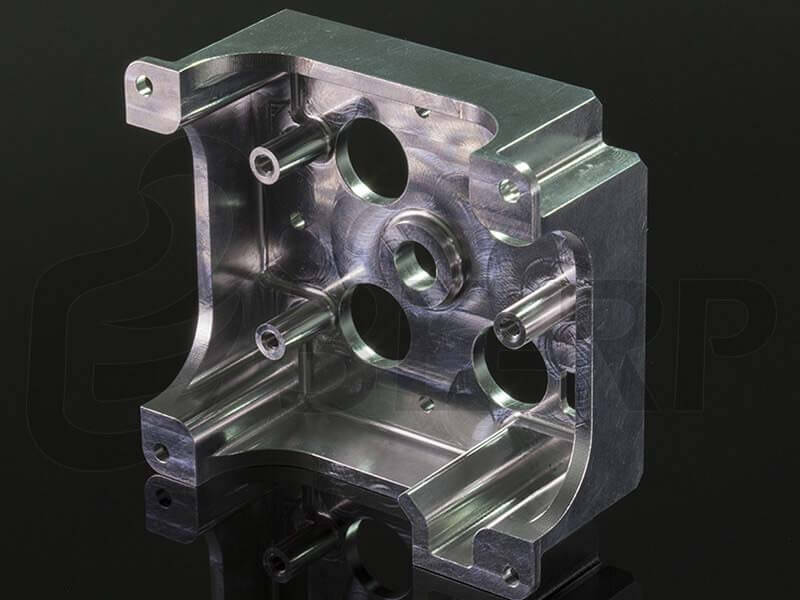

We strongly agree with this prediction, as each of the major (and even minor) 3D printing vendors has recently refocused their marketing efforts towards segments that actually make money. One of the most profitable segments is, of course, metal 3D printing. It still occupies a niche where equipment and materials can be priced very highly – and is still purchased by sufficient numbers of clients in certain industries, such as aerospace and medical applications.

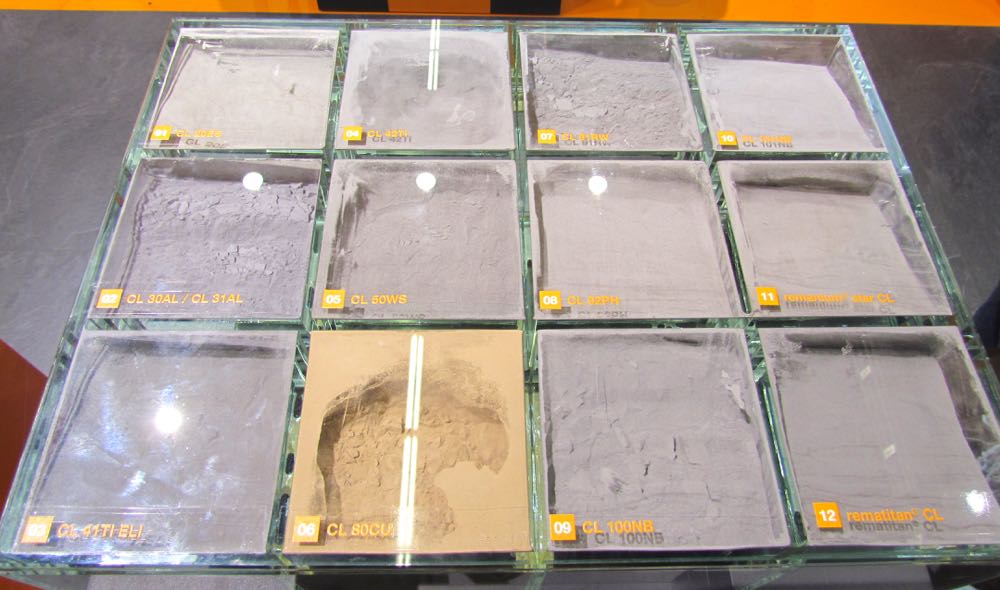

2. Growth in Metal Powder Supply Chain Will Struggle to Keep Pace With Demand

This is possible, especially if prediction #1 comes true. However, there are many metal producers in the world and if any are looking for additional revenue streams, it’s entirely possible they may switch over some of their production capacity to produce suitable metal powder in rapid succession. A similar kind of switch happened when the plastic industry discovered 3D printing and suddenly there were seemingly dozens of very capable filament production houses competing for customers. The same could happen for metal powder.

3. Automotive Industry Will Invest Significantly in Metal Systems for R&D

We’re not sure this will happen. Yes, this did and continues to happen in the aerospace industry, but that industry is somewhat different from the automotive industry, as issues of weight and performance are absolutely critical elements for aerospace applications. Meanwhile, the automotive industry does have those objectives, but not nearly as strongly. Worse, the automotive industry must employ low cost parts as the final products are purchased by consumers, unlike the aerospace industry where parts are often quite expensive.

4. Alternative Print Material Feedstocks Enhance, Not Threaten, Opportunities for Metal Powders

SmarTech is talking about non-powder-based metal 3D printing, for example where a robot arm wields a welding apparatus. They believe such equipment and associated materials will not threaten traditional powder-based metal 3D printing. We agree with this, simply because there really aren’t many such systems available today.

5. Small Footprint Metal AM Systems Will Drive Growth

Here SmarTech predicts that those marketing the large and expensive metal 3D printers will develop smaller versions that could enable new styles of manufacturing. We agree with this for the simple reason that if a large system is profitable, it should be possible to downsize it and reach more customers at a similar (or better) level of profitability. Case in point: Stratasys did so when they introduced their uPrint plastic 3D printer, which was priced quite a bit less than their flagship models. The uPrint was able to not only enable less-funded organizations to get into industrial 3D printing, but often led to future sales of the bigger gear. It’s a strategy, see?

Via SmarTech