Researchers from several institutions have performed more extensive testing on particulate emissions from commonly available 3D printers, and the results should be known by all 3D printer owners.

The one study we previously saw involved testing for quantities of nanoparticles. The study, from 2013, showed that substantial quantities of such particles were emitted by heating the plastics involved in the operations. They found that ABS plastic seemed to emit far more particles than PLA, but said little about the potential toxicity.

Since that study emerged, we’ve been concerned about this effect and have taken steps to minimize risk (e.g. refraining from use of ABS). Now a new study has delved a lot deeper into this topic and found some important results.

How did they go about testing? They set up a lab in the configuration shown at top. The setup could capture and measure the airborne particulates emitted by the equipment. They tested no less than sixteen different plastic filaments used by five different 3D printers:

- Flashforge Creator

- Dremel 3D Idea Builder

- XYZprinting da Vinci 1.0

- LulzBot Mini

- MakerBot Replicator 2X

The filaments included ABS, PLA, HIPS, Nylon, Polycarbonate, PET and some composite filaments made from PLA mixed with other materials. These filaments were not tested on all machines, but only on machines they were compatible with.

Testing involved printing a specific test object in each case, to ensure the conditions were otherwise identical.

Findings were interesting. Here’s our highlights:

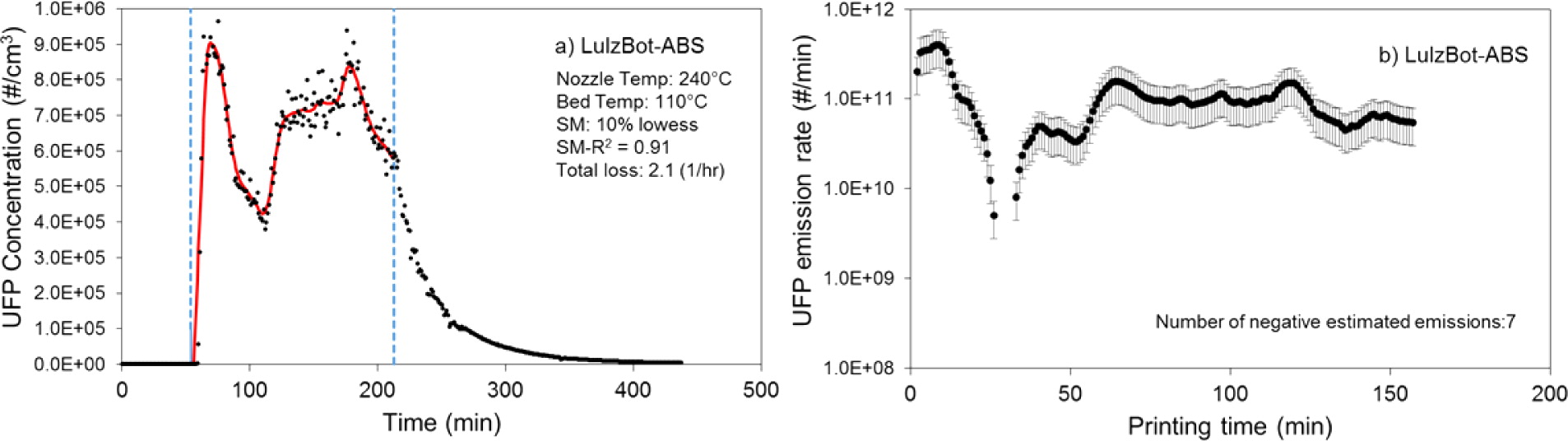

This chart shows emissions by temperature. It appears that ultra-fine particles (UFPs) are emitted at LOW temperatures as well as print operation temperatures!

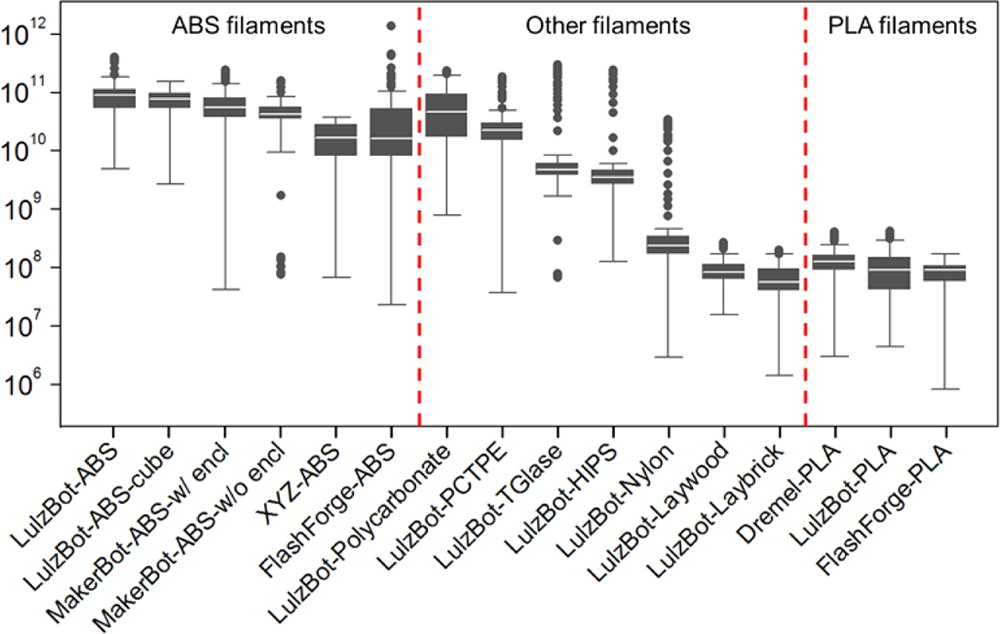

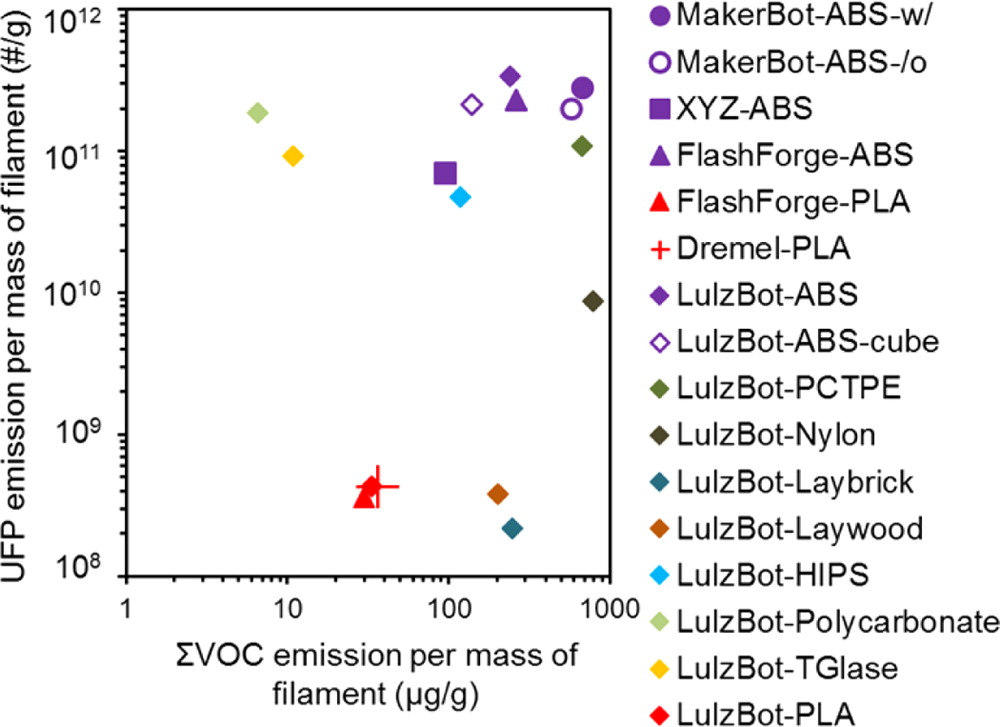

Plastic types vary in emissions, with ABS being the heaviest emitter. Somehow this is not surprising, given the very noticeable odor when printing ABS.

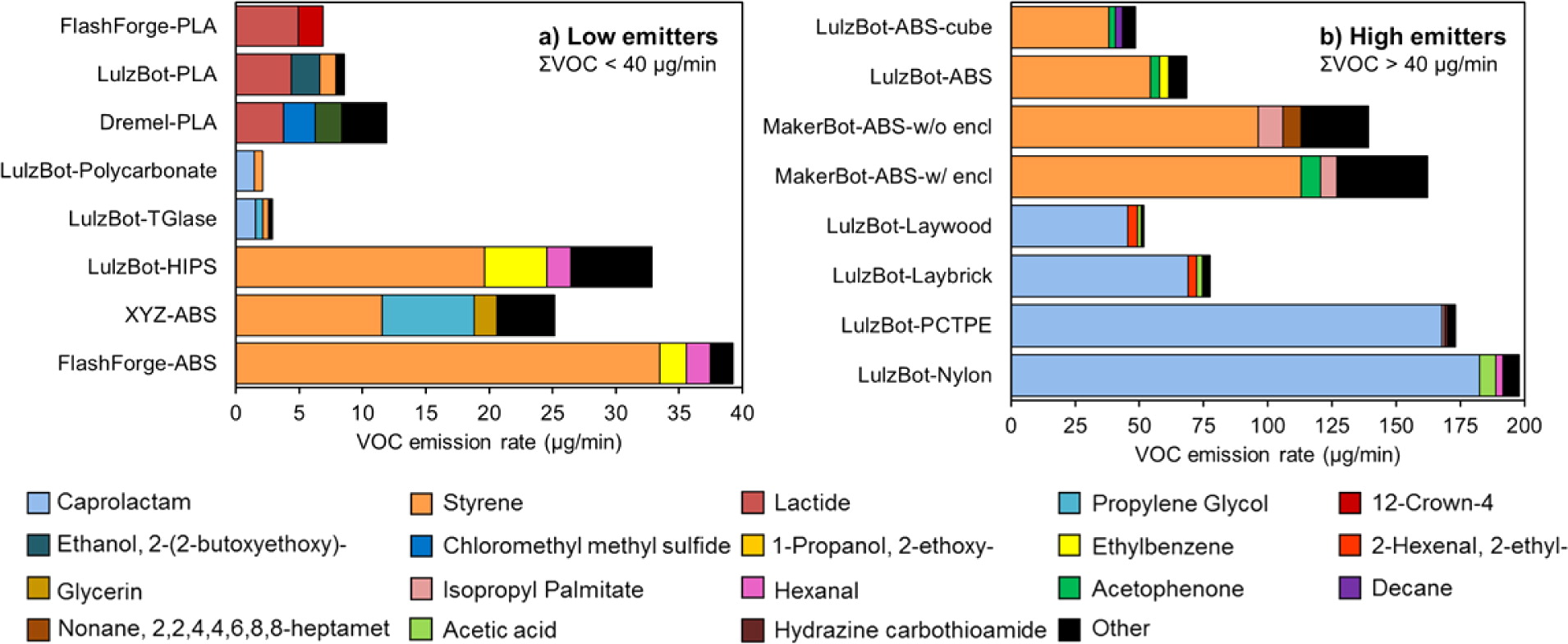

This chart shows the lowest emission configurations and the highest emission configurations. As you can see, there is clearly less emissions for certain types of plastics. But note that some of the same machines appear on both high and low charts, suggesting that it’s really the materials that matter.

Here we see the machines/plastic combinations charted. Again, the machine itself doesn’t seem to matter much; instead it’s the material that matters.

Here’s key sections from their conclusion:

Styrene, which is classified as a possible human carcinogen by the International Agency for Research on Cancer (IARC classification group 2B), was emitted in large amounts by all ABS filaments and the one HIPS filament. Caprolactam was also emitted in large amounts by four of the filaments: nylon, PCTPE, laybrick, and laywood.

We should also note that this analysis does not take into account proximity effects that could serve to substantially elevate exposures to both UFPs and VOCs in certain microenvironments compared to well-mixed conditions.

The predicted caprolactam concentration (244 μg/m3) would exceed all three RELs identified by the California OEHHA, which suggests that although there is considerable uncertainty in this estimate, exposure to caprolactam from desktop 3D printing in a typical office environment with nylon and nylon-based filaments could lead to adverse health outcomes, particularly for susceptible individuals. Acute exposure to high concentrations of caprolactam is known to be “irritating to the eyes and the respiratory tract” and “may cause effects on the central nervous system”, according to the Centers for Disease Control and Prevention (CDC).

The predicted styrene concentration in this configuration (150 μg/m3) would be approximately 20 times higher than the highest styrene concentration measured in commercial buildings in the U.S. EPA BASE study and more than 20 times higher than the average concentration in U.S. residences. There are also reports that suggest exposure to styrene at these concentrations could be problematic for human health.

The study then recommends further measurements, and asks manufacturers to do two things:

- Develop low-emission materials. We’ve actually seen a couple of these already appear, and after this study it might seem like a really good idea.

- Develop sealed enclosures to capture the UFPs before they reach the environment. Again, we’ve seen a very few machines that are sealed and equipped with appropriate filtration mechanisms. This should be mandatory on all 3D printers going forward.

Once again, we strongly suggest anyone using a 3D printer ensure they have more than the minimum ventilation when operating such a machine.

Via ACS Publications