We chatted recently with Fuel3D CMO Philip Newman and learned the company has taken some big steps, and they’re not in 3D printing.

Fuel3D’s first product launched in the summer of 2013 with a very successful Kickstarter campaign, raising well over USD$300,000. From there, the company continued to refine it’s main product, the Scanify 3D face scanner, which subsequently led to substantial external investments that enabled the company to fundamentally change its path.

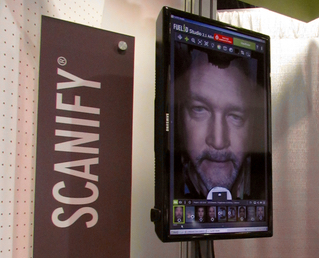

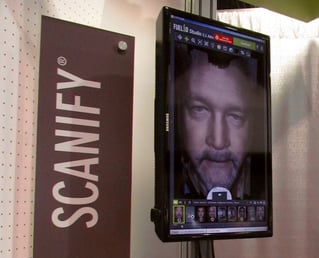

The Scanify was intended to quickly and accurately capture faces for purposes of 3D printing or use in visual 3D applications. But from that straightforward beginning, the company has now branched out into a myriad of 3D applications, demonstrating the versatility of their core 3D scanning process.

It turns out that Fuel3D’s rapid structured light 3D scanning process can be applied in a number of unique ways, and the company seems to be pursuing many of them quite aggressively. In fact, Newman says they really have what he calls, “opportunity overload”.

Aside from their handheld Scanify, they’ve been working on a desktop scanner, a prototype of which is shown here.

Here we see a prototype of a 360 degree “head scanner”. The Scanify was able to only capture one side of a head, usually the face, but this new unit is essentially seven Scanify engines linked together that perform multiple captures that are automatically stitched together, able to collect highly accurate color and texture information. The objective is to produce a usable 3D scan in five minutes instead of five hours, as is sometimes done with other technologies. This speedup turns out to be critically important when, say, scanning multi-million dollar actors for use in 3D content vehicles.

Just for fun, we captured a 240fps video of the head scanner in operation. Normally the scan takes place so quickly that it’s hard to see the individual flashes of structured light, but here you can see at least some of the sequence.

There are a number of areas being actively investigated by Fuel3D. One is Eyewear, where the concept is to 3D scan a face, and then virtually apply a perfectly-formed set of eyeglasses to the 3D face. This rendering could potentially be 3D printed later, should the customer select that option. Fuel3D is looking to develop some sort of kiosk-like device that could be installed in optometry offices to enable everyone to access the technology.

And that’s just one concept. There are many more.

Another is to develop perfectly-fitting custom orthotics through a 3D foot scan and sophisticated analysis software. Essentially they 3D scan the foot in different positions to derive the optimal orthotic shape.

It seems they’ve realized that the acquisition of the human shape enables the creation of many types of custom products personalized to the individual. It’s a huge potential market.

Yet another application is biometrics, where they are investigating possible applications in the security area. We got the impression they were far along in this development, but were unable to describe what they were doing.

Manufacturing applications are also possible; Fuel3D intends to develop ways to accurately capture shapes for use in 3D manufacturing processes. It’s part of their move from their initial 3D printing hobbyist market to a much larger (and profitable) enterprise market.

Have they abandoned the original Scanify? By no means! They’ve continued to improve it, primarily on the software side. The Fuel3D Studio application was just upgraded to version 2.1, and is now quite powerful and simplified, able to stitch scans together, for example. They’ve also developed a cloud engine that will not only speed processing, but increase detail.

The cloud platform is very interesting, because it theoretically permits any device to run Fuel3D Studio, since there is no longer a requirement for powerful processing and graphics.

The company has also developed what they call their “Cat Bird Algorithm”, which is a new approach to greatly improve Z-axis scanning precision. Apparently you can even apply the new algorithm to previously scanned objects! It’s likely that the cloud platform enables this algorithm to be implemented in a practical manner.

All this tells us something about Fuel3D: while the hardware is similar in these applications, the key is in the software that implements each application. Thus, Fuel3D has transformed from a scanner company into a software company.

Via Fuel3D