We took a close look at the gigantic ProX DMP 320 metal 3D printer from 3D Systems.

This machine is massive, as you can see in the image above featuring 3D Systems’ metal printing tech Jim Fenlon, who specializes in supporting the gargantuan ProX DMP 320.

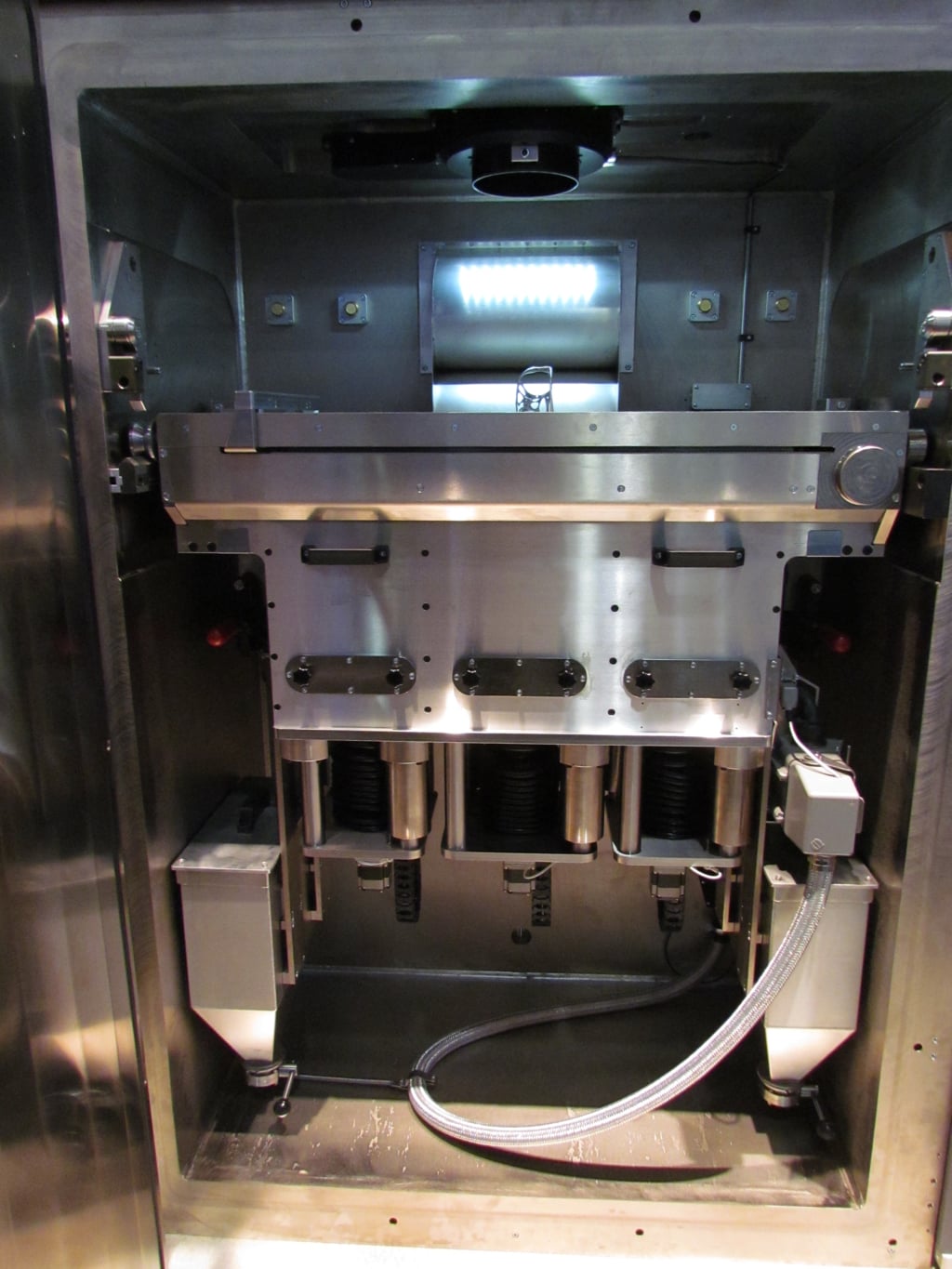

The 320 uses the Direct Metal Printing process, which involves a high-power laser that selectively melts fine metal powder, layer by layer, to form complete metal objects. 3D Systems explains that the resulting objects are chemically pure and compatible with EN ISO 2768 machining tolerances, with approximately 20 micron accuracy.

The 320 is one of several machines in 3D Systems’ line of “DMP” machines, offering a healthy build volume of 275 x 275 x 420mm, the largest volume provided by any 3D Systems metal printer. What’s interesting about the 320 is that it’s has modular configurations, allowing specialization in either titanium or stainless steel/nickel super alloy, achieved with a specialized laser collimator. It’s a direct descendant of the machines and technology from Layerwise when it was acquired by 3D Systems in 2014.

Aside from the USD$750-800K “all-in” price for the 320, you’ll have to ensure your install site provides heavy-duty three-phase 400V input power. Argon gas, used to prevent reactions between atmospheric oxygen and finely-powdered metal, is supplied from an external source. You’ll also need to provide a compressed air source, used to create the vacuum employed during active printing.

Printing safety is always a concern, and it appears this machine is designed with that as a top priority. One safety feature is to separate machine from its filter, which may contain reactive metal particles. While 3D Systems recommends use of a certified dust proof mask during operations, it’s also possible to remove the build tank for separate post-print activities, which also permits near-continuous use of the 320 if you start a second job while unloading the first.

Even though the behemoth 320 is shipped mostly assembled, you’ll need a tech to set it up for you, which apparently takes a day or two to get going, according to Fenlon.

The 320 seems to be part of 3D Systems’ recent push into metal 3D printing, which is an area set for significant growth as more companies discover the benefits of 3D metal design and printing.

Via 3D Systems