We continue to hear growing interest in metal 3D printing. Is there a reason for this? We think so.

In fact, a recent report from CONTEXT, a market research firm, indicates that sales of metal 3D printing gear rose 45% year over year.

If you look at the long term pattern here, the interest in metal 3D printing is a continuation of the awareness of 3D printing capability by industry.

Initially, 3D printing was used solely as a prototyping tool, primarily because the available materials were suitable only as prototypes and not usable for production parts. Many companies created great market advantages for themselves using 3D printing for prototyping. 3D printing, however, was often viewed as a kind of “weak” method of making as a result.

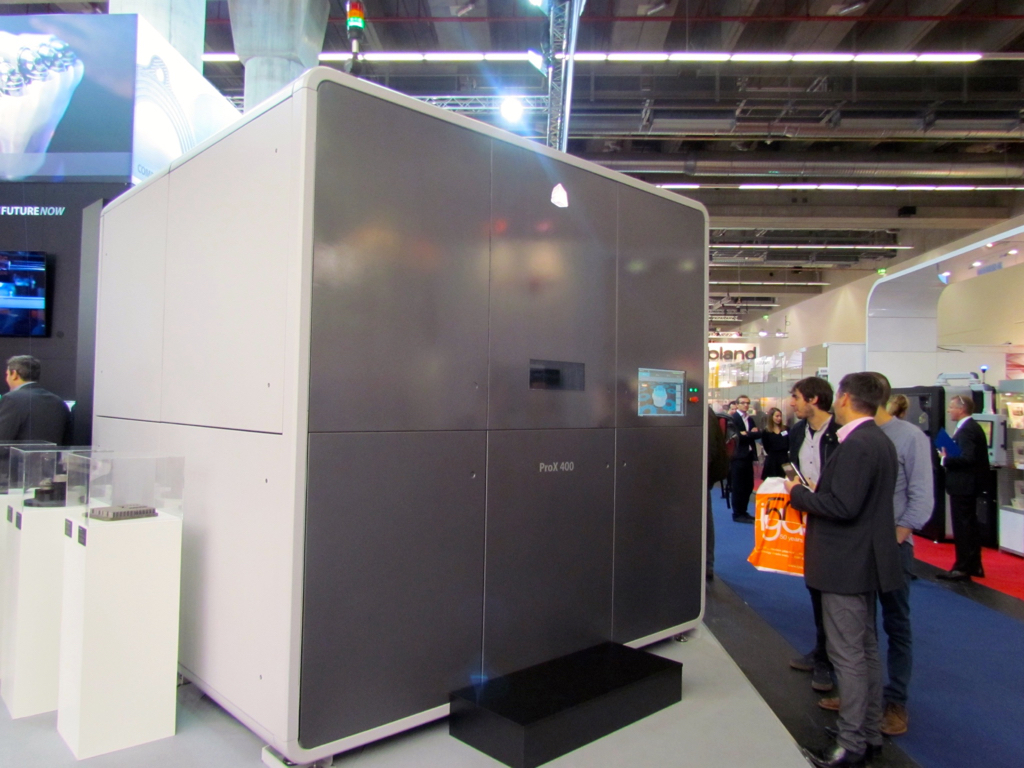

However, some 3D printers are able to 3D print in metal powders, initially from lesser-known companies with limited distribution channels, making it less probable a prospective client would know of their existence. But later, the major 3D printer companies acquired or partnered with metal 3D printer makers, significantly raising the awareness level of 3D metal printing as a concept.

Now we see companies realizing the metal parts they can obtain from metal 3D printers are quite suitable for use in production roles. In fact, they are able to further leverage 3D printing processes by making parts that might be extremely difficult or impossible to make using other processes.

Once used by one manufacturer, their competitors will quickly get the idea and have to keep up by instituting their own metal 3D printing capabilities. Thus, we have a small explosion of the technology underway.

It’s also very good news for the 3D printer manufacturers, as their metal equipment carries a much higher profit margin over their plastic equipment, perhaps due to increasing competition by less expensive plastic 3D printers recently available.

We believe the interest in 3D metal printing will continue to grow: there are an awful lot of manufacturers out there that still do not make use of the technology.

Via PRNewsWire