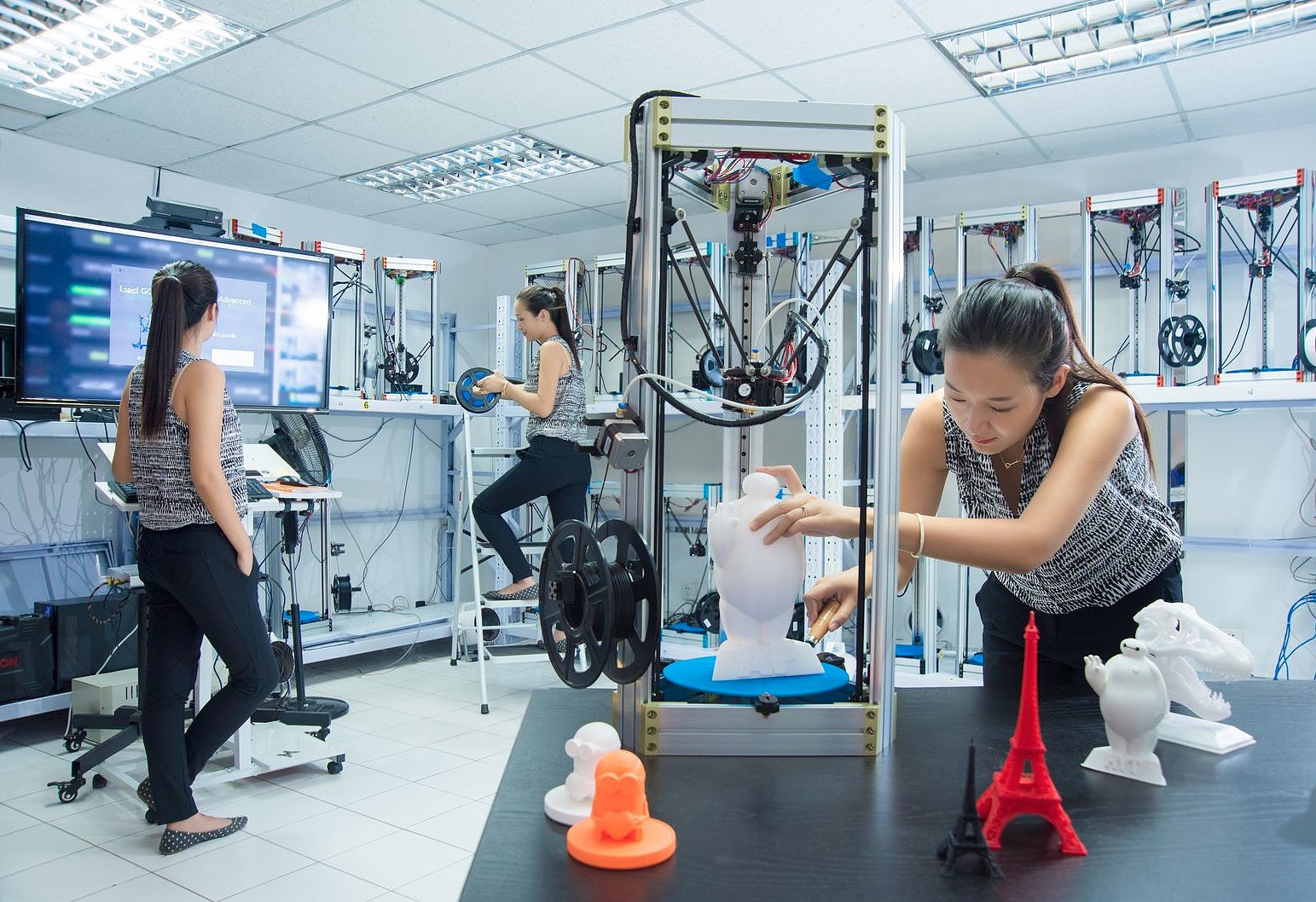

We’re checking out a new 3D print service, Printaworld, which boasts of a 100+ unit 3D printer “farm”.

The idea here is that to overcome the invariably slow process of 3D printing, you can print more objects per unit time by doing so in parallel.

Imagine the scenario where you need 100 copies of an object printed. On a typical 3D printer, this might take you, say, one hour to print one item. If you’re more ambitious (and risk-taking) you could arrange for multiple copies of the object to be printed in a single print job by arranging them across the print surface. So you can print, say, six objects in six hours or so. That really doesn’t speed up the total print time, does it? It would still take you 100 hours, more or less, to produce 100 units.

3D print services using big equipment use this approach too, although their typically powder-based machines allow you to “stack” objects in 3D space within the print volume, not merely in 2D on the print plate. But the same calculations occur.

But if you had two printers, it would take you only fifty hours (or so) to complete the 100 units.

Printaworld takes this much further by operating over 100 separate 3D printers. The New York state-based company operates a number of different types of 3D printers, including those with plastic extrusion, UV-cured resin and powder-fusion processes.

They say:

Need Parts in 24 Hours? We will get you covered. 1 to 50+ Pieces in 1 day.

and

1-50 Pieces Finish in 1 Day Next Day Delivery* or Local Pick-Up

*For New York City or Tri-State Area only. Other areas depend on the distance and order quantities.

This is quite different from the service obtained from some competing 3D print services, where you might wait days or even weeks to receive your parts.

With the increasing quality and reliability of 3D printing equipment, particularly at the commercial level, there’s decreasing differentiation between 3D print services. One way for a service to distinguish itself from others is to focus on one aspect, such as service quality, ease of use, or something else.

Like print speed.

This method could be a harbinger of what we might see in the future: very large scale 3D print services located in regional areas within one day shipping of target destinations. In the future, there might be 3D printing regional factories with over 1,000 printers present. Then things start to change.

And in the case of Printaworld, they’ve not only got a lot of Delta 3D printers, but they’ve also seemed to have cloned their system operator, too!

Via Printaworld