Most commercial metal 3D printers use powder-based techniques, but there’s another approach: deposition welding.

We’re looking at the additive manufacturing technology from TRUMPF, a German company specializing in industrial lasers. Most of their products are actually subtractive tools, not additive, such as laser cutters, surface texturing, laser welding and similar processes. But they do offer something called “Deposition Welding”. It’s also sometimes described as “DMD”, or Direct Metal Deposition.

Deposition welding as a manual concept has been around for a while. TRUMPF explains manual deposition:

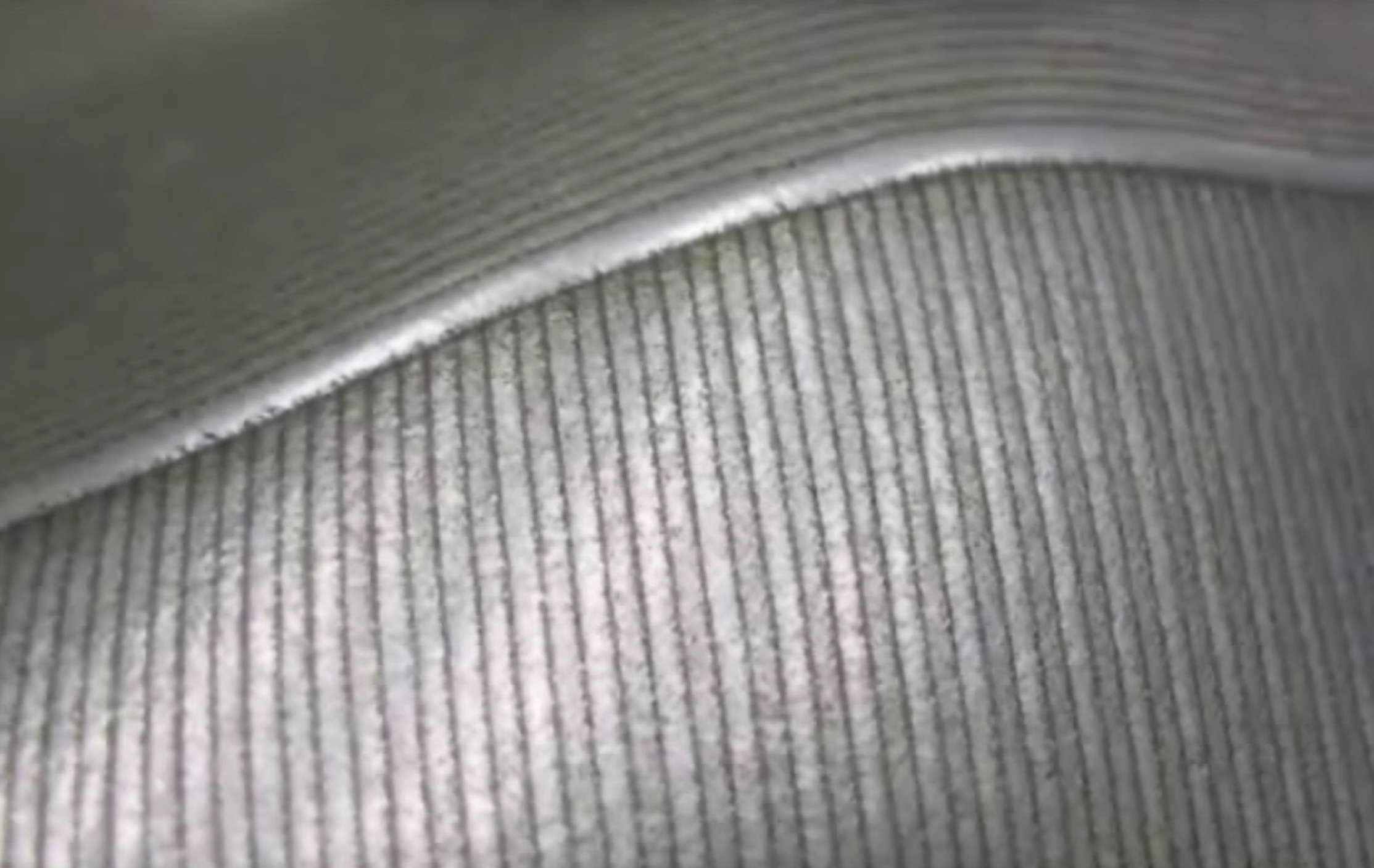

the welder guides the filler material “by hand” to the area to be welded. A thin wire with a diameter between 0.006 and 0.02 inches is primarily used as filler material in this process. The laser beam melts the wire. The molten material forms a strong bond with the substrate, which is also melted, and then solidifies leaving behind a small raised area. The welder continues in this fashion, spot by spot, line by line, and layer by layer, until the desired shape is achieved.

However, one could automate the process by controlling the deposition process by machine. TRUMPF explains how they do it:

In automated deposition welding, the machine guides the filler material to the area to be welded. Although the material can also be a wire, this process primarily uses metal powders. Metal powder is applied in layers to a base material without pores or cracks. The metal powder forms a high-tensile weld joint with the surface. After cooling, a metal layer develops that can be machined. A strength of this process is its ability to build up a number of metal layers.

Basically, a robot arm guides a special toolhead over a surface, as you can see in this video. The toolhead blasts out a stream of powdered metal material that is instantly melted by up to 6,000W of energy. The melted metal fuses with the surface. Repeated applications can produce layers of added material, just like a 3D printer.

The catch with this approach is the it must be done over an existing surface, and so TRUMPF portrays their products as tools for repairing surfaces. But it could also be used to print entire objects if directed appropriately.

The DMD approach is also used by a couple of other companies, such as Optomec and DMG Mori, who happen to make an industrial machine that’s both a 3D printer and a CNC mill combined.