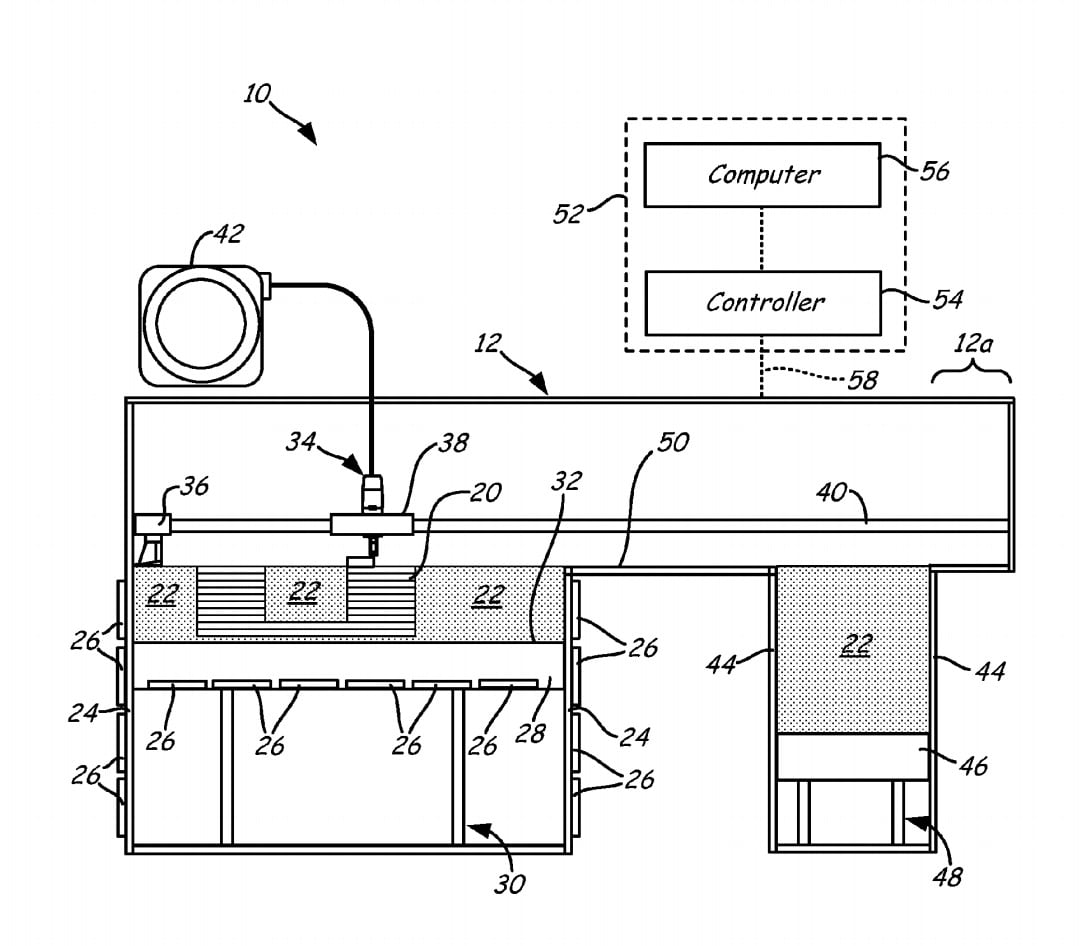

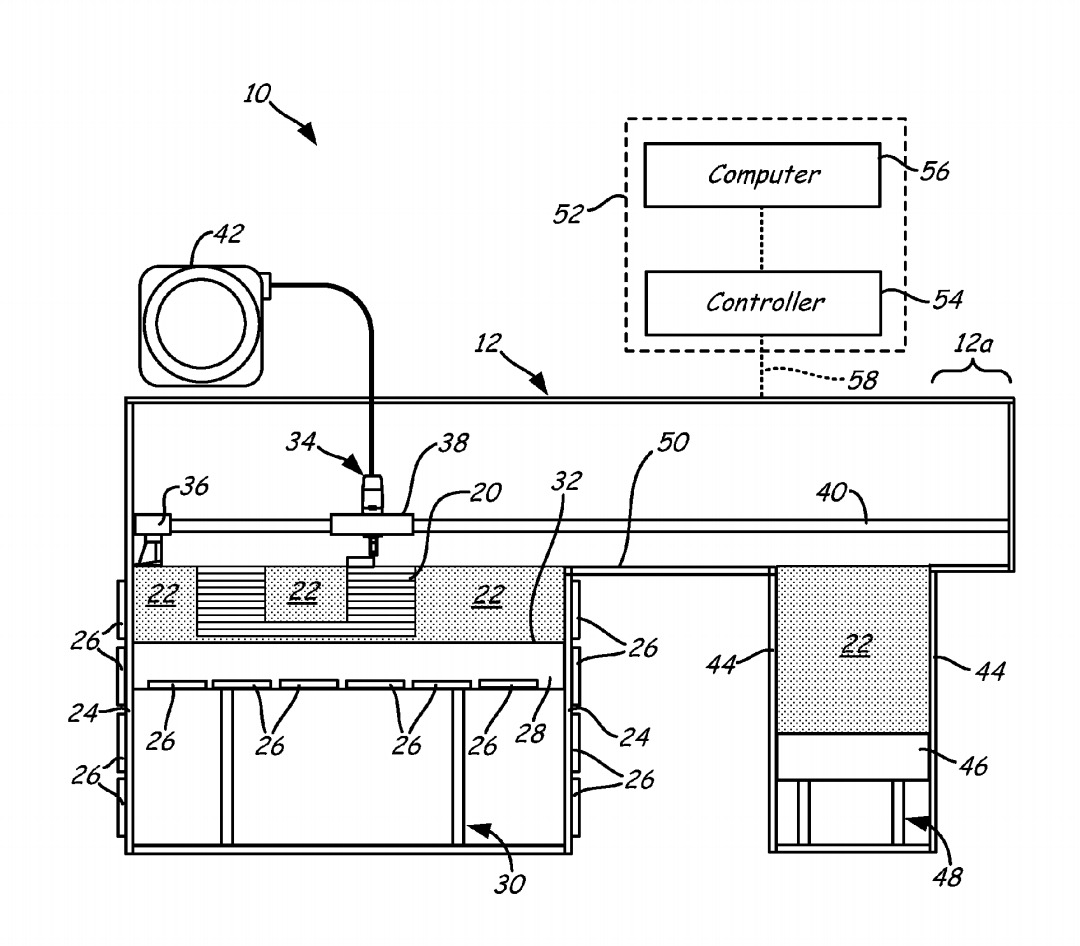

On October 1st, the USPTO published a patent application from 3D printer manufacturer Stratasys for an unusual method of supporting 3D prints: magnetic media.

US Patent publication number US20150273582 A1 is entitled: “System and Method for Printing Three-Dimensional Parts with Magnetic Support Media”, and that’s exactly what it’s about: supporting prints with magnets!

The problem they’re trying to solve is that of support structures. If you’re not 3D printing with a powder-based process, you often need to generate support structures. These are fully functional and definitely permit successful 3D printing, but the issue is after the print completes: you must remove the support structures.

Typically removal is done by dissolving the support material, if it’s been designed for that. It requires a special tank with chemicals for dissolving, and often requires considerable time to complete. Another approach is to manually remove the support structures, which is not only tedious but requires relatively expensive labor hours to complete and can damage the print if done improperly.

Enter the idea of magnetic support material. Here’s how it is supposed to work:

- A hopper is filled with magnetic media, which is essentially a bunch of tiny balls that can be affected by a magnetic field.

- As each layer of the print occurs, the “unprinted” portion of the layer can accept a layer of magnetic media distributed from the hopper.

- The distributed magnetic media is held fast by a magnetic field inside the build chamber.

- The print proceeds, with a mixture of model material and magnetic support material on each layer.

- When the print complete, the magnetic field is disabled, and the magnetic support material falls away from the print. Done!

This approach has two very interesting advantages:

- There is little effort required to separate the print from the support material, although it’s possible some might get trapped inside cavities if the magnetic material distribution places it incorrectly.

- The inevitably expensive magnetic material can be re-used! This is the first instance of reusable support material we’ve seen, outside of powder-based machines.

We’re not aware of any Stratasys machine using this approach, but it could be of great value if it was, particularly for production shops that run their industrial 3D printers continuously, as this feature could significantly reduce the amount of manual labor required to complete prints.

If only we could get a glimpse into Stratasys’ secret labs, we might see one of these in action.

Via Google