Stratasys and partner Aurora Flight Sciences have developed an incredible demonstration of 3D printing capability: a 240kph jet-powered UAV.

We’ve been trying to stay away from “3D print stunts” lately, but this venture by Stratasys definitely deserves mention as it proves a few key points.

The challenge facing many 3D printer producers is to persuade skeptical manufacturers that 3D printing can be an exceptionally viable process. Stratasys in particular has targeted several industry segments that are most amenable to the beneficial effects of 3D printing, including aerospace.

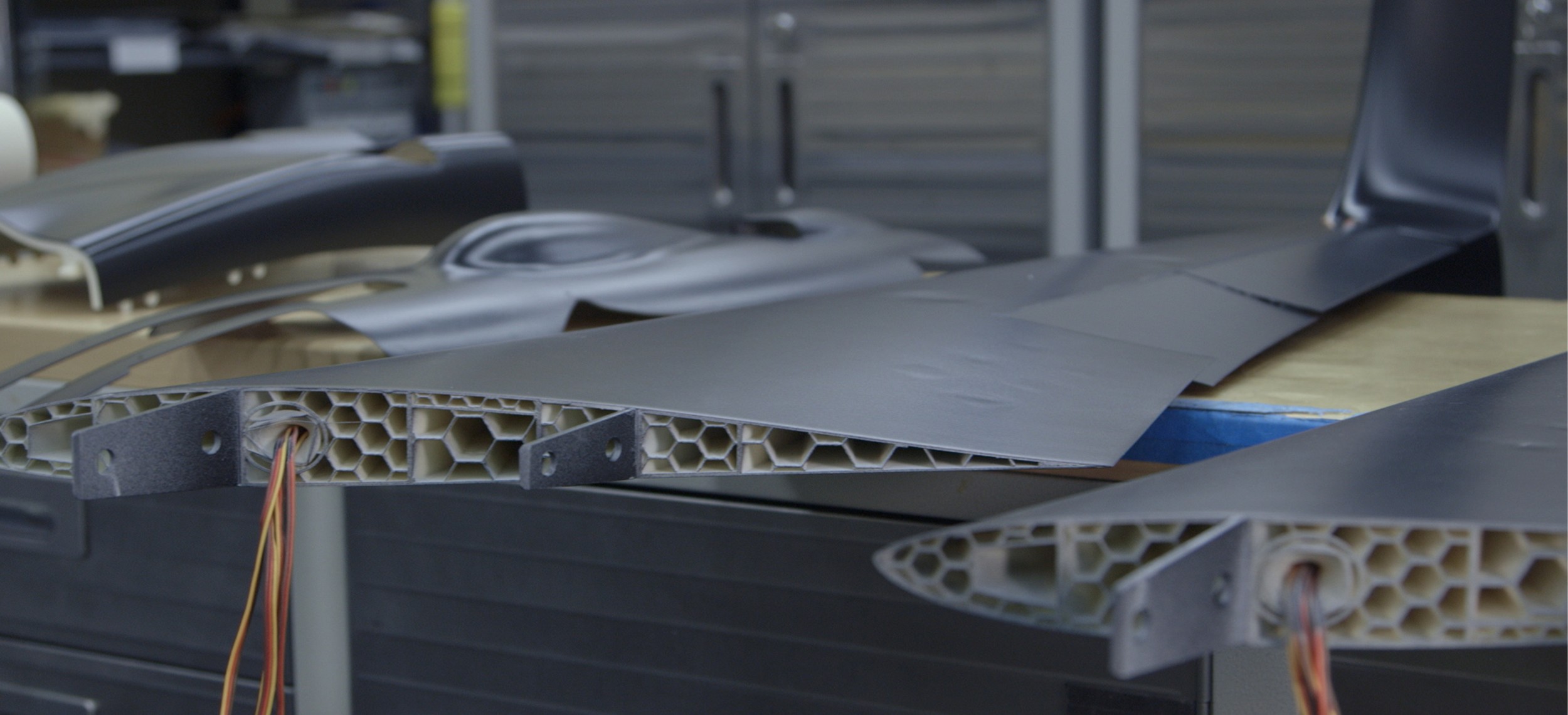

Which leads us to their latest demonstration. Partnering with Aurora Flight Sciences, the team designed – and successfully flew – a UAV made from 80% 3D printed parts by weight. The majority of the UAV was made from FDM (plastic extrusion) technology, while a few other elements were 3D printed in metal and other materials.

The resulting UAV is literally jet-powered, and can reach speeds of an astonishing 240kph (150mph). In the video above, you’ll see it deftly zooms through the skies at incredible speed. This UAV works!

But now for the interesting parts: What did Stratasys really demonstrate here?

First, they’ve clearly shown that you can create a more-than-functional production-ready UAV with (almost) only 3D printing technology. For those who might doubt the ability of 3D printed parts to be usable in a real-world machine, this may change their mind. Stratasys hasn’t demonstrated long-term durability with this test, but it’s a great start.

Secondly, they’ve shown that such a production device can be quickly designed and built at relatively low cost. They claim this UAV required only half of the design and build time as using conventional development approaches. How did they achieve that? By leveraging the ability of 3D printing to create a design with fewer, but more complex parts. These required fewer iterations and less assembly time. Again, this is meant to convince skeptical manufacturers that there is something to this 3D printing buzz.

And they’re right.

Via Stratasys