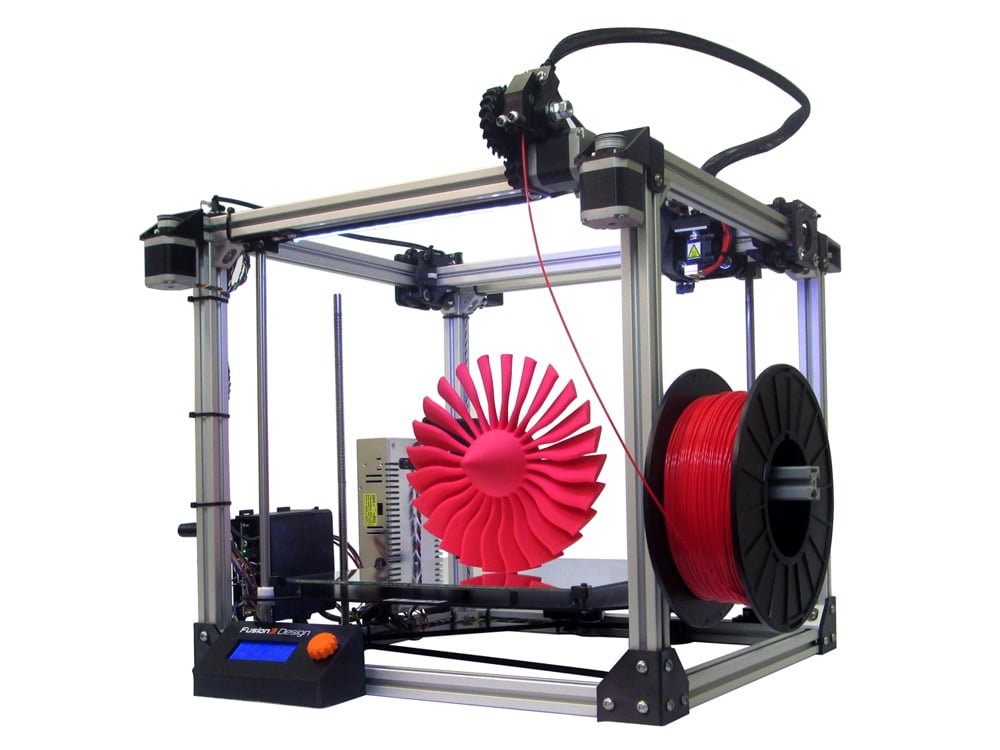

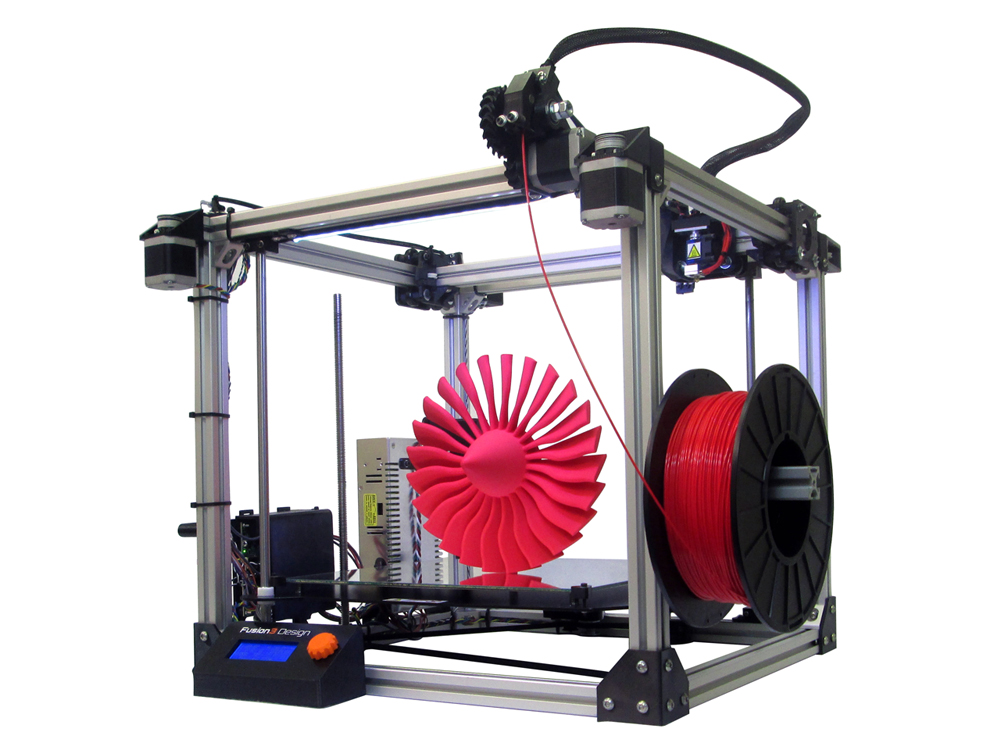

Fusion3 is a small but growing manufacturer of high-quality desktop 3D printing equipment, including their latest F306 machine.

The F306 doesn’t have a fancy case or giant color touch screens, but it is carefully designed for high-quality 3D printing. We recently had a tour through the machine and found a number of very interesting features that could make this machine quite attractive to industry looking for lower cost prototyping solutions.

Their extruder motion mechanicals are designed for accuracy and speed. Using a Bowden approach, they’ve removed the weight of the extruder motor from the moving toolhead. They also include a unique XY drive system in which the motors do not travel with the axis; they’re positioned on the frame in a stationary manner. Thus, the toolhead motion deals with as little weight as possible. You might think this design includes more items that could break, but they’re using braided spectra cable (kevlar) instead of timing belts to transfer motion.

The result is a motion system that they describe as “stiff, light and fast”. How fast? Print speeds are normally 100mm/s, but they can achieve 200mm/s or even 250mm/s depending on the material. They’ve found ABS is the easiest to print at higher speeds, which work well on their 300W multi-zone heated print plate. However, they say it’s best to use a glue stick to ensure print adhesion. This is important as their build volume is reasonably large: 305 x 305 x 305mm.

There’s one other interesting result of the mechanical design: they say their layer-to-layer alignment is within 25 microns (0.025mm). We find this quite interesting, because we have not heard any other manufacturer cite this particular metric. It essentially describes how smooth the vertical walls will be, and is of utmost importance for quality finishes. We can’t tell you the number of times this alignment has been found poor on other machines, making crappy prints.

The machine can print most materials, but does have “feed issues“ with Ninjaflex, as many other printers do.

The company appears committed to quality, even with respect to their shipping method. They do not trust regular shippers, who, as most readers have experienced, can mishandle shipments of carefully calibrated equipment such as 3D printers.

Instead, Fusion3 ships only via LTO Freight, which is much more reliable but also more expensive. They ship straight from the factory and essentially subsidize individual or small business buyers by charging only USD$149 for shipping. As a result, when you receive your F306, it will be perfectly calibrated from the factory and should be ready to go.

Pricing for the F306 is a bit more than for most desktop units, at USD$3,975 for a single extruder and USD$4,975 for a dual extruder.

While those prices might be a bit steep for individuals, the price is definitely right for small (and large) businesses looking for an alternative to much more expensive industrial 3D printers. In fact, the F306 also uses generic 3D printer filament, meaning the operational costs are also low. It sounds like many companies are buying one F306 to test out their quality, and then buy several more. One of their customers says:

Parts that took much of the day on a Makerbot only take 1-2 hours on the F306. Also, the print quality from the F306 (resolution and finish) is better than the same parts printed on expensive Stratasys FDM printers. Very nice job on the F306 Printer!

Fusion3’s service plan is also quite interesting. While they offer a standard six month warranty, you can also purchase a USD$985 annual service plan, which they call “Ask Us Anything!” They’ll provide support not only for the printer itself, but seemingly on any related aspect of 3D printing, including materials, software, modeling, profiles and more.

Contemplating an inexpensive industrial-quality 3D printer? You might consider the Fusion3 F306.

Via Fusion3