Berlin-based BigRep announced a new version of their flagship 3D printer, the One.3.

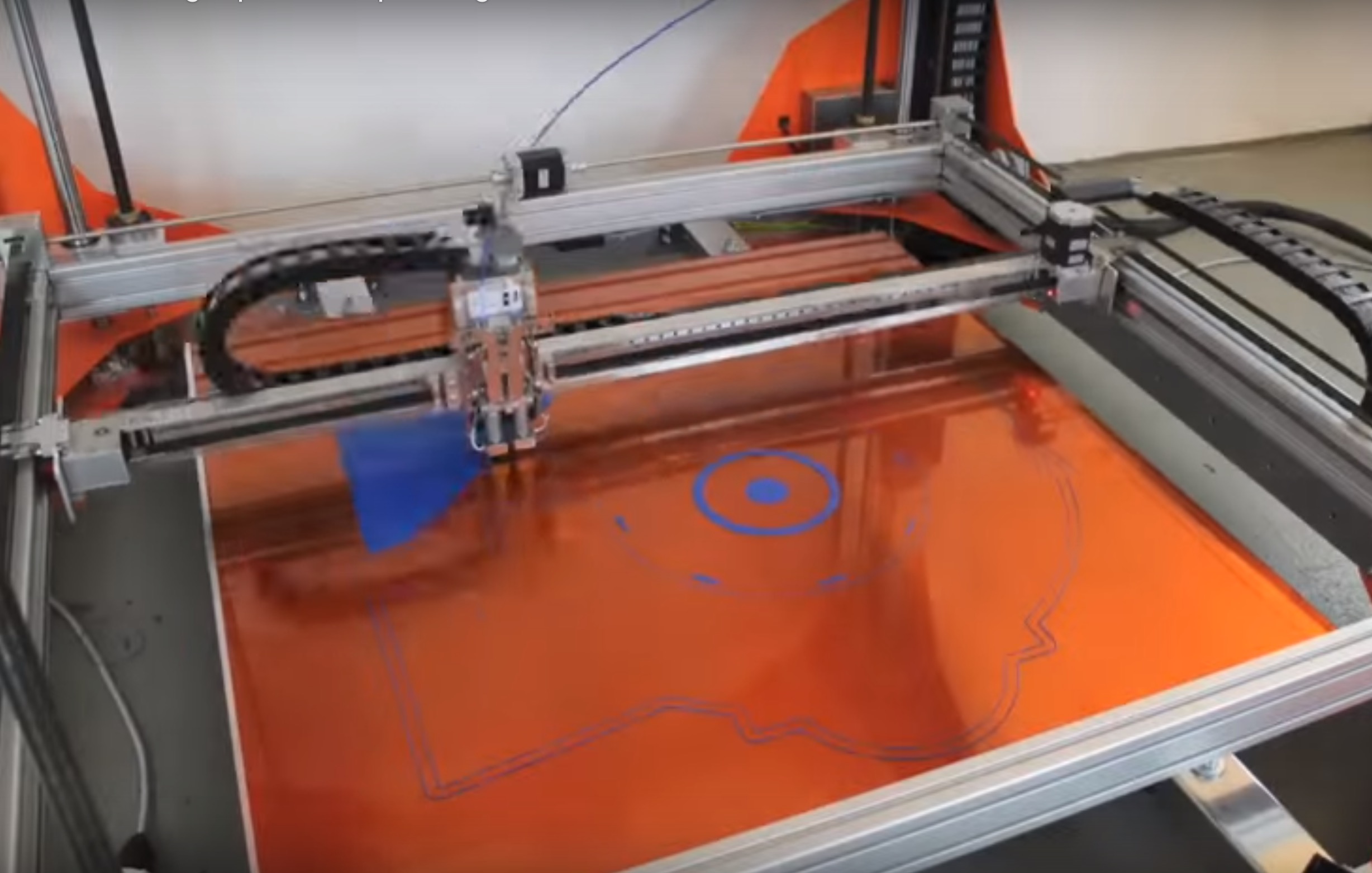

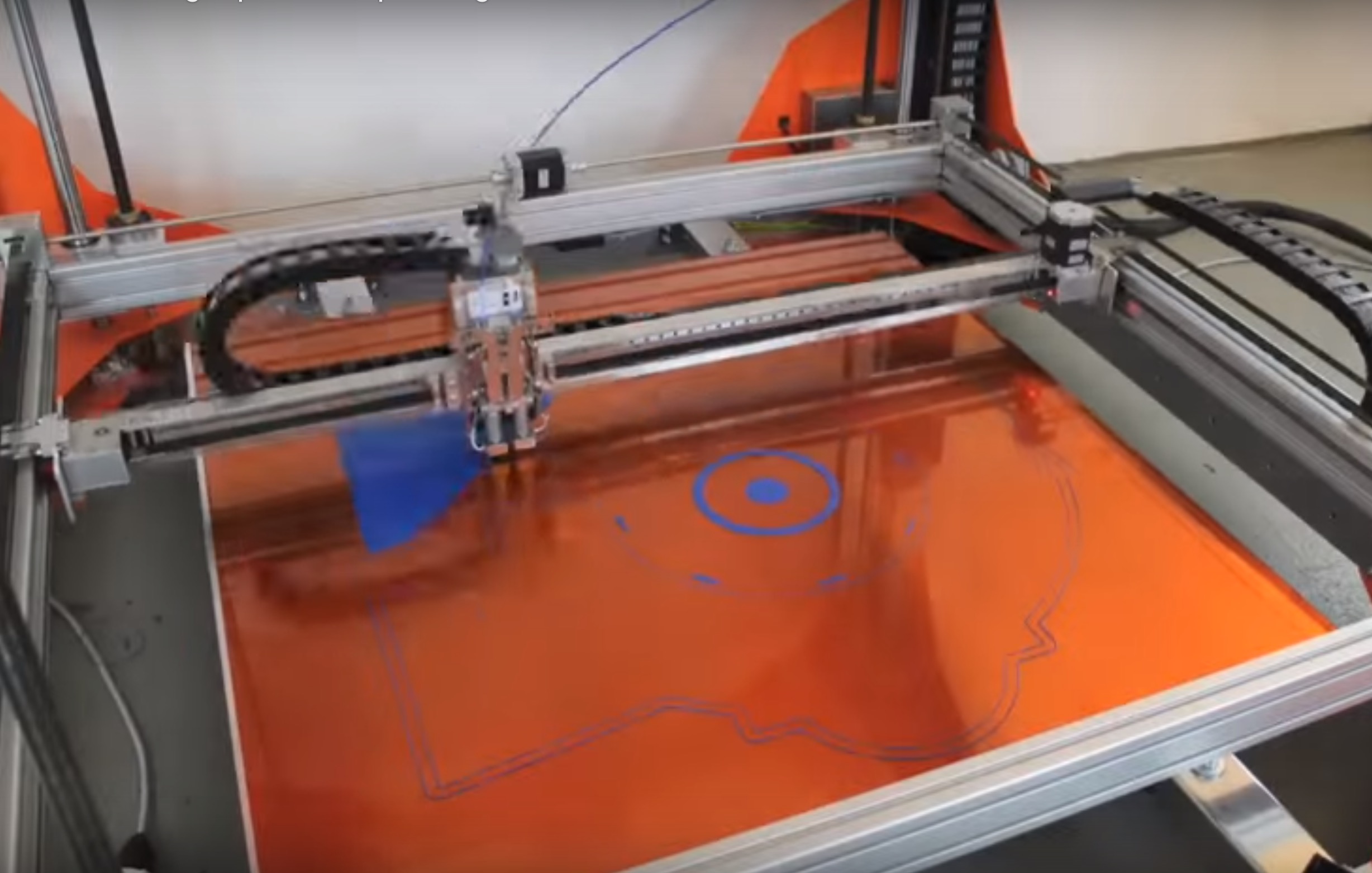

We’re always amazed to see this incredibly large 3D printer in person, as pictures definitely do not demonstrate the ridiculous size of this machine. It can 3D print objects as large as a meter on a side!

The company has been around for a couple of years now and they’ve clearly been learning more about 3D printing massive objects, as their new One.3 3D printer includes several features designed to make life a lot easier when printing giant parts in their 1100 x 1050 x 980mm build volume.

3D printing at that scale is a bit different from smaller-scale equivalents. You’ll need considerably more raw material, for starters, as well as very reliable hardware that can take you through to the end of the print job without failing.

But BigRep has enhanced the machine by adding these very useful big-scale print features on the BigRep One.3:

The new modular extruder can not only be swapped quickly, it can also detect “end of filament” scenarios that would otherwise ruin a long 3D print and waste literally kilograms of plastic. If detected, the printer pauses and awaits a reload. You can also use different sized nozzles, which is critical for speeding up massive prints.

The print bed is now auto-leveling! This process previously took some time to complete, being such a large bed. Now, it’s automatic.

The spool mount is changed to permit a variety of different spool styles to be accommodated. It can now hold up to FOUR spools of 10kg each. You can load this machine with 40kg (88lbs) of plastic filament! That should enable you to print objects that can fill the entire print volume without need for reload. But that might take you a very long time to complete. Weeks, for sure.

Finally, the One.3 catches up with smaller 3D printers by adding a GUI-based touch panel for direct control of operations. The GUI is also accessible through the Internet via a web page or smartphone app.

Due to the huge build volume, you’re able to 3D print only non-warping materials, such as PLA, PVA or HIPS. Printing ABS plastic may result in stronger parts, but ABS is challenging to print on much smaller 3D printers and couldn’t be attempted at BigRep scales, even with its improved heated print surface.

If your workshop floor can support the 500kg weight of the BigRep One.3 and its USD$38K list price, you might want to look into acquiring one when it’s released this fall.

Via BigRep