Researchers at the University of California, Riverside have determined that at least some commonly used 3D printing materials are toxic.

The discovery was triggered when Shirin Mesbah Oskui, a graduate student, realized the 3D printed parts she had made for use in studying zebrafish were affecting them in negative ways. The research team decided to investigate further.

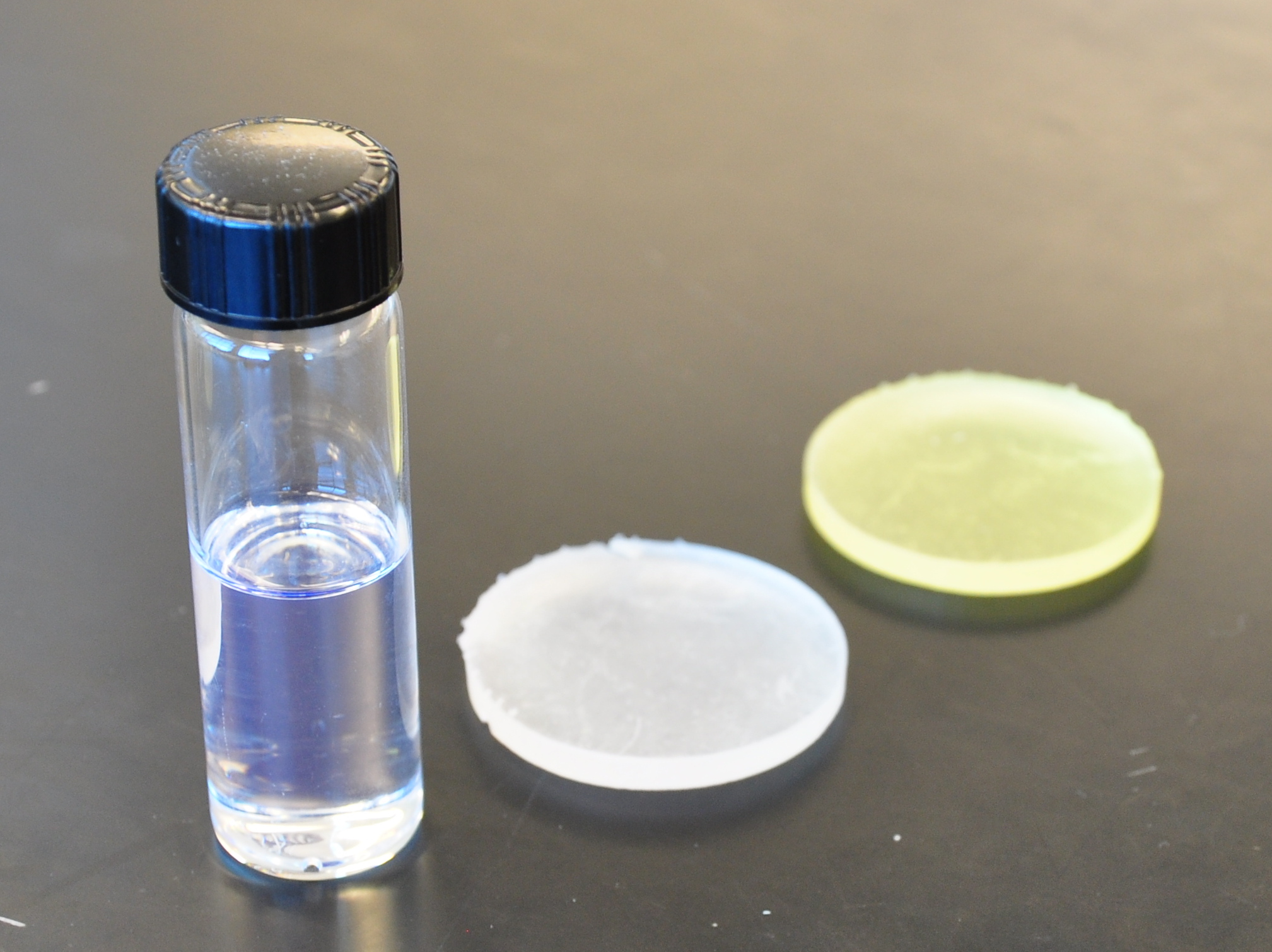

Two styles of 3D printing were examined: plastic extrusion and photo-cured resin. To perform the test, they produced uniform objects on each of two commonly available 3D printers, the Stratasys Dimension Elite (plastic extrusion) and Formlab’s Form 1+ (photo-cured resin).

These printed samples were placed in zebrafish tanks to observe their effects on fish embryos and compare to “control” tanks without the samples.

The effects were:

While the embryos exposed to parts from the plastic-melting printer had slightly decreased average survival rates compared to control embryos, the embryos exposed to parts from the liquid-resin printer had significantly decreased survival rates, with more than half of the embryos dead by day three and all dead by day seven. And of the few zebrafish embryos that hatched after exposure to parts from the liquid-resin printer, 100 percent of the hatchlings had developmental abnormalities.

That’s definitely not good.

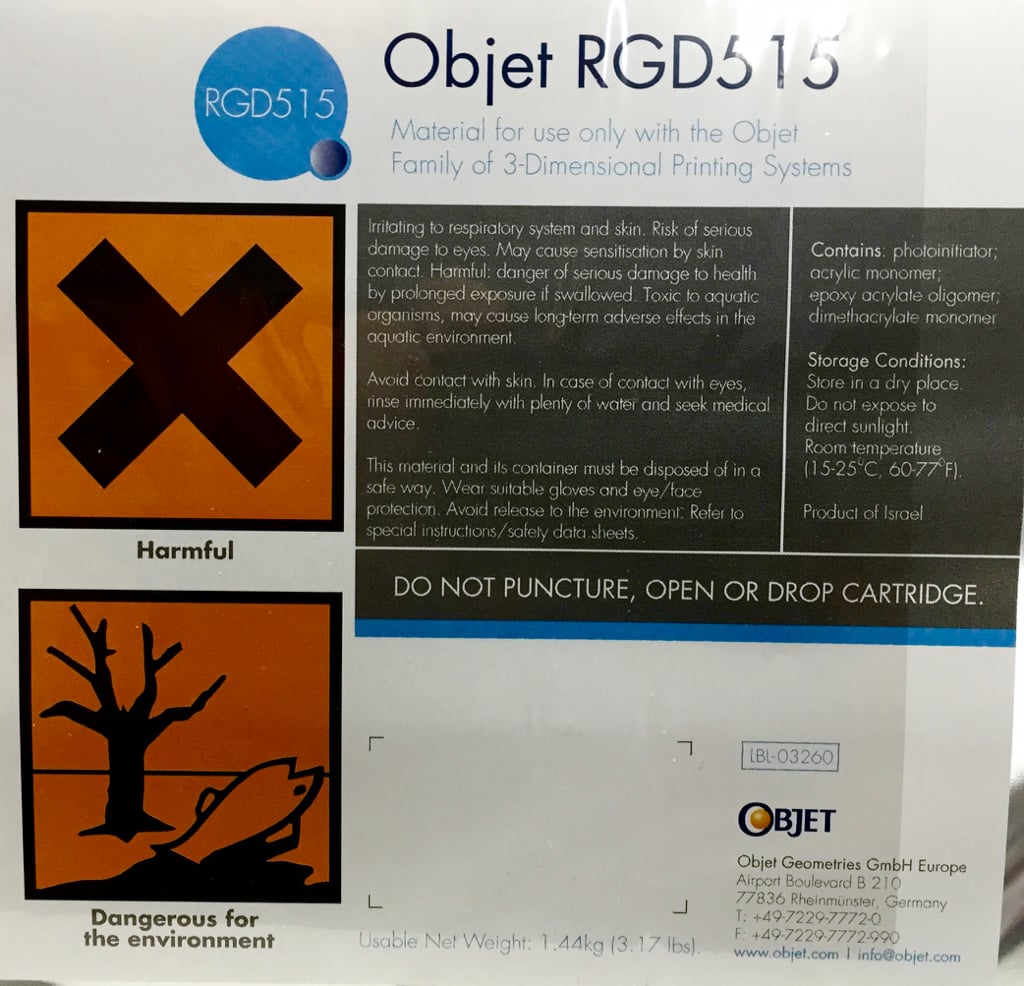

We’ve suspected an effect like this may be real, as we’ve been reading the sometimes scary labels found on resin canisters for machines we’ve been using, like this one. For fun, you should read the MSDS sheets for materials you’ve been using.

Is there anything you can do about this? Certainly we would strongly advise you have proper ventilation in your 3D print workshop, or filtration of appropriate nature.

There may be more solutions available in the future, as the researchers have also been working on minimizing the toxicity effects observed. Essentially, they realized that by exposing the freshly 3D printed resin parts to ultraviolet light for an hour or more, they could significantly reduce the toxic effects.

This makes sense, as freshly printed parts typically have a syrup of non-solidified liquid resin residue on their surfaces.

However, they’ve patented this process, apparently, and so you’ll have to wait until they come up with a commercial solution. Or just buy an ultraviolet light and bathe your parts in UV on your own.

Via University of California, Riverside and ESTLET (Paywall)