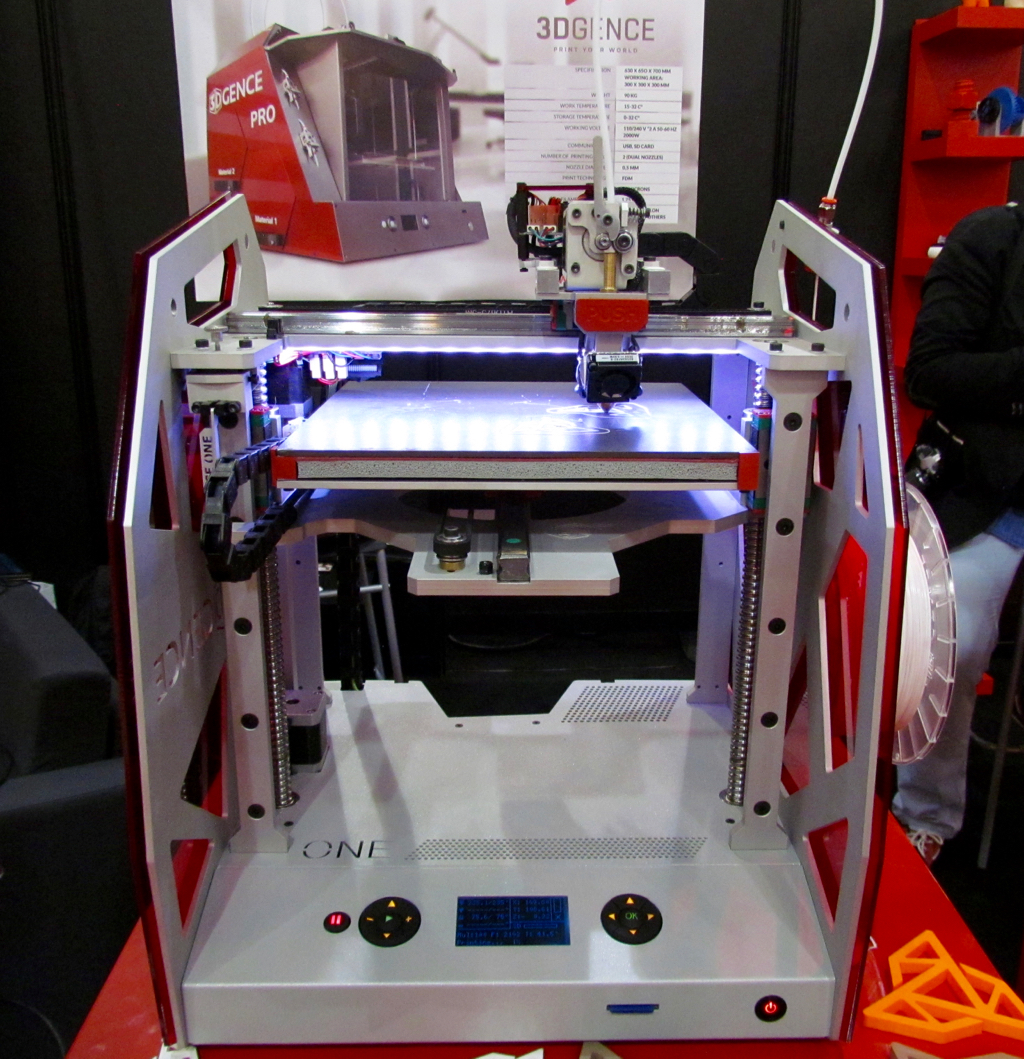

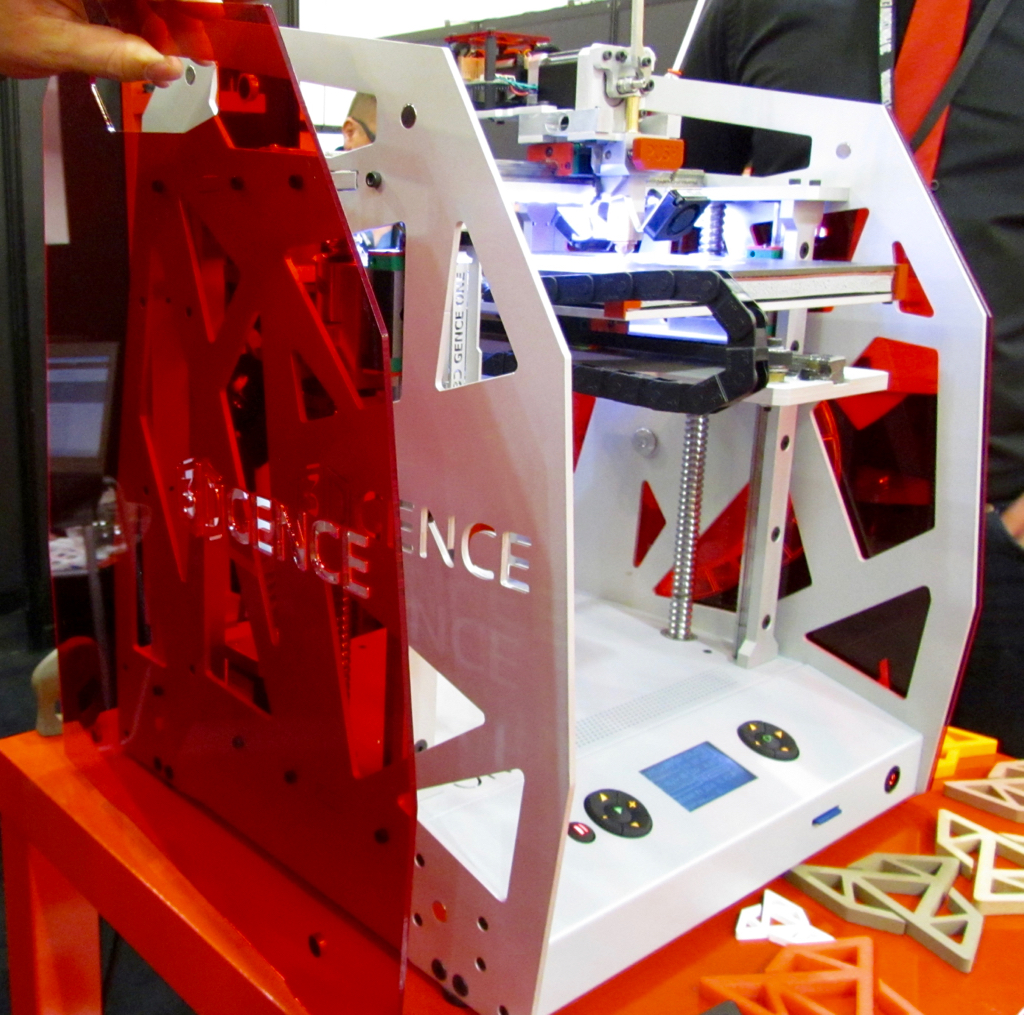

We got a close look at 3DGence’s new ONE 3D printer and saw features we haven’t seen in any other machine.

The Poland-based company has developed a top-class machine that should be suitable for professionals. They began with a universal mount and built a 3D printer around it.

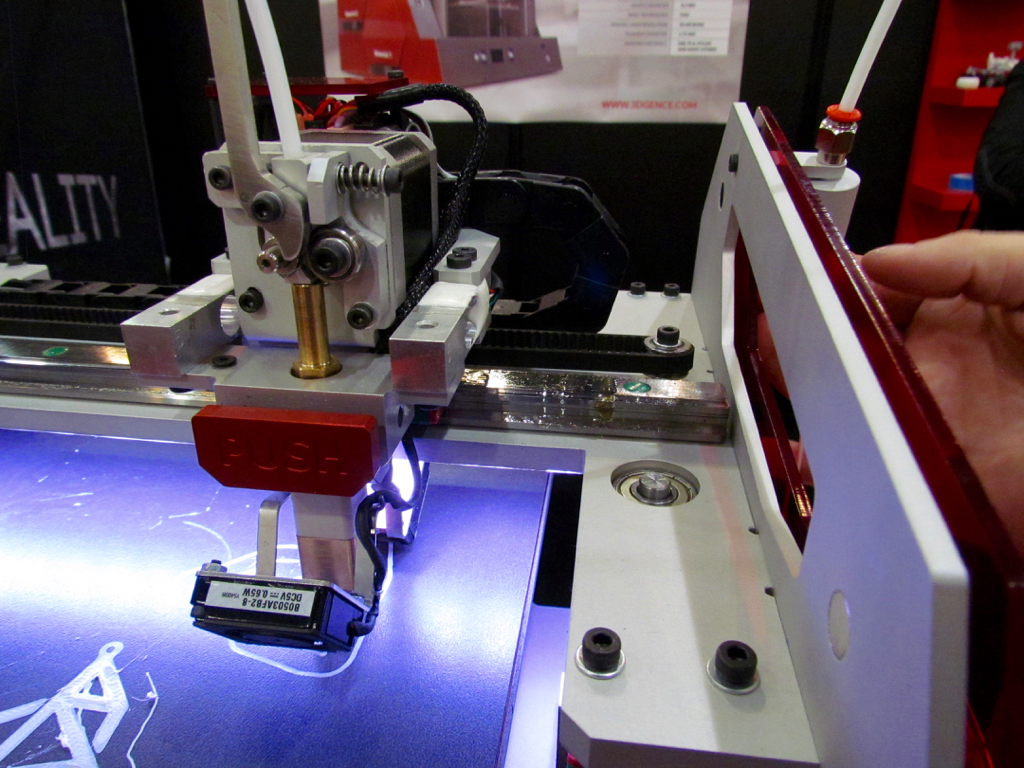

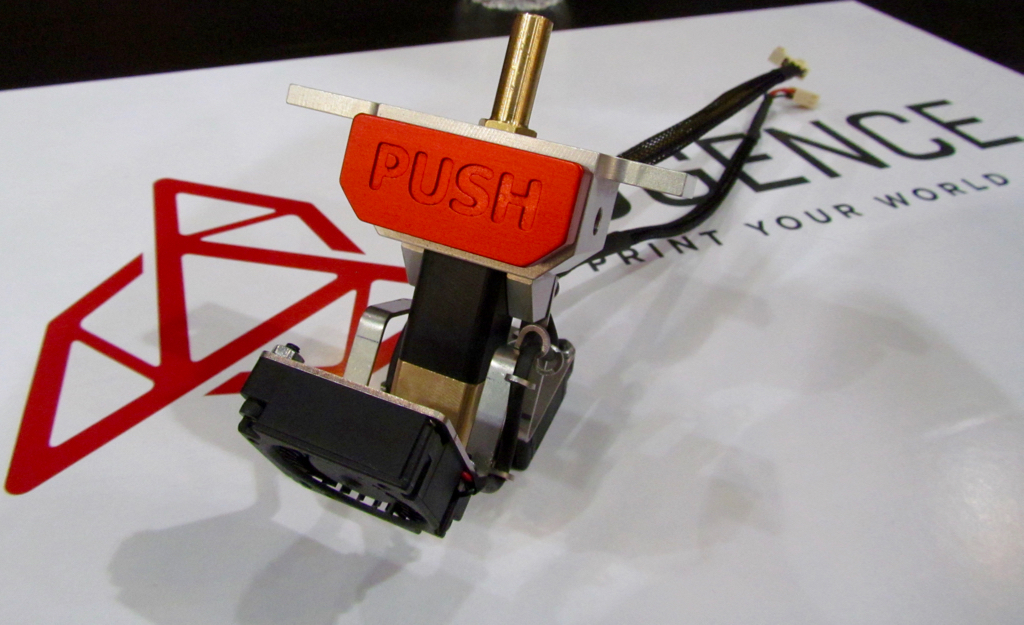

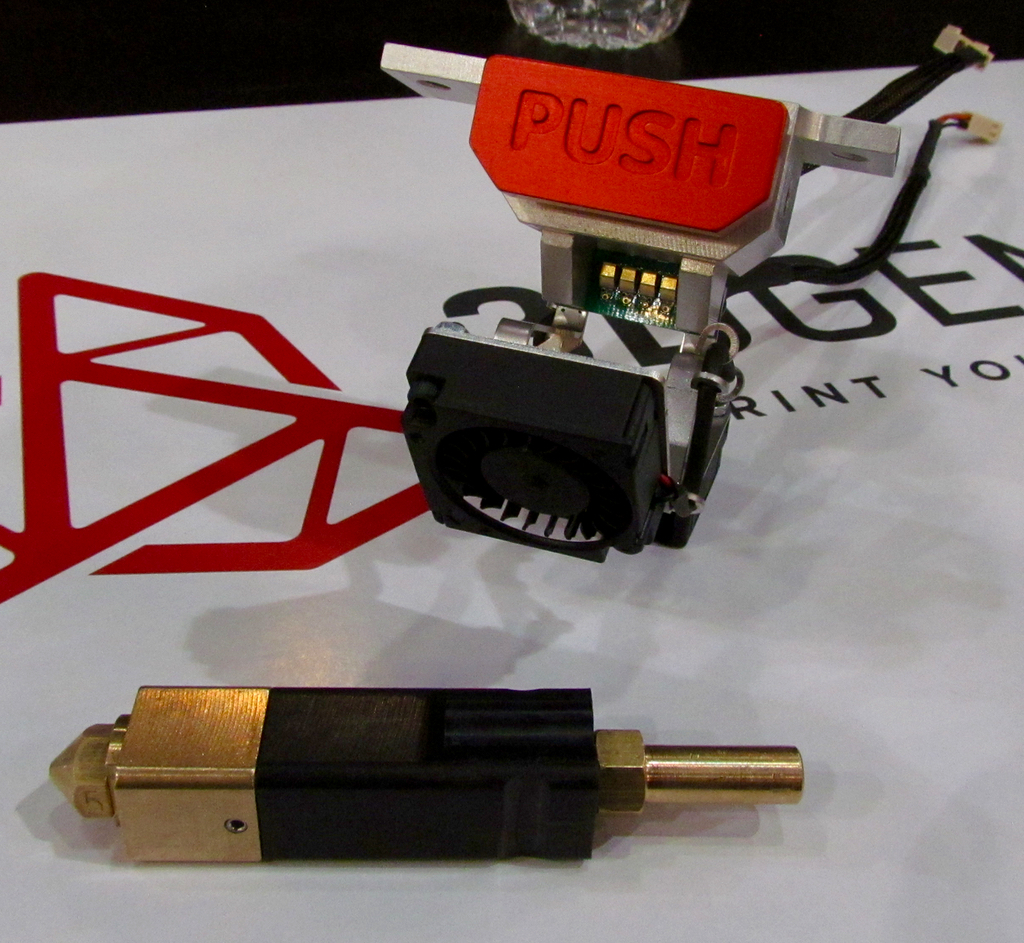

The extruder is quite interesting. Here you see the assembled hot end, which can print layers as small as 0.06mm.

With the touch of a button, you can instantly remove the hot end for cleaning, swapping with different sizes or replacement.

The “ONE” is entirely calibrated automatically. What’s really interesting is that the machine can perform a detailed sensor test of the ceramic print surface on 400 locations. From this it records a “topological profile” of the print surface – and uses it to dynamically adjust the z-height to account for not only tilt, but non-flat surfaces, too.

This sensor scan is done at the factory, but you can initiate another one if necessary – it takes only 15 minutes to complete.

The ceramic print bed is also interesting itself: 3DGence says it sticks to prints better, and freely releases prints when it cools. The ceramic material lasts longer and is mostly impervious to chemical action. They say the bed can be heated to ready state in only five minutes, and the hot end in under one minute.

The side panels can be swapped, and you can order any of three colors to go with the white or black anodized aluminum base machine.

They’re expecting to launch the machine in the next month or two, with a cost of approximately USD$3,500 per unit.

Via 3DGence