While designers spend considerable time in CAD software tweaking their 3D models, did you know it’s also possible to optimize STL 3D models, too.

We took a look at Cyborg3D CAD2Print, a powerful STL file manipulation utility from San Diego-based IntegrityWare. This company has been running since 1996 and has considerable experience in advanced 3D processing, including even building part of Rhino3D and other popular 3D CAD programs in the past. They market a number of expert-level 3D model processing software and CAD plug-ins, but now have introduced Cyborg3D, a tool specifically designed for optimizing STL files for 3D printing.

Why would you want to fiddle with your STL file after your CAD program has exported it? There are several reasons, but primarily the objective is to transform the raw STL into something that’s optimally formed for 3D print file preparation. In other words, make the STL “friendly” to slicing programs.

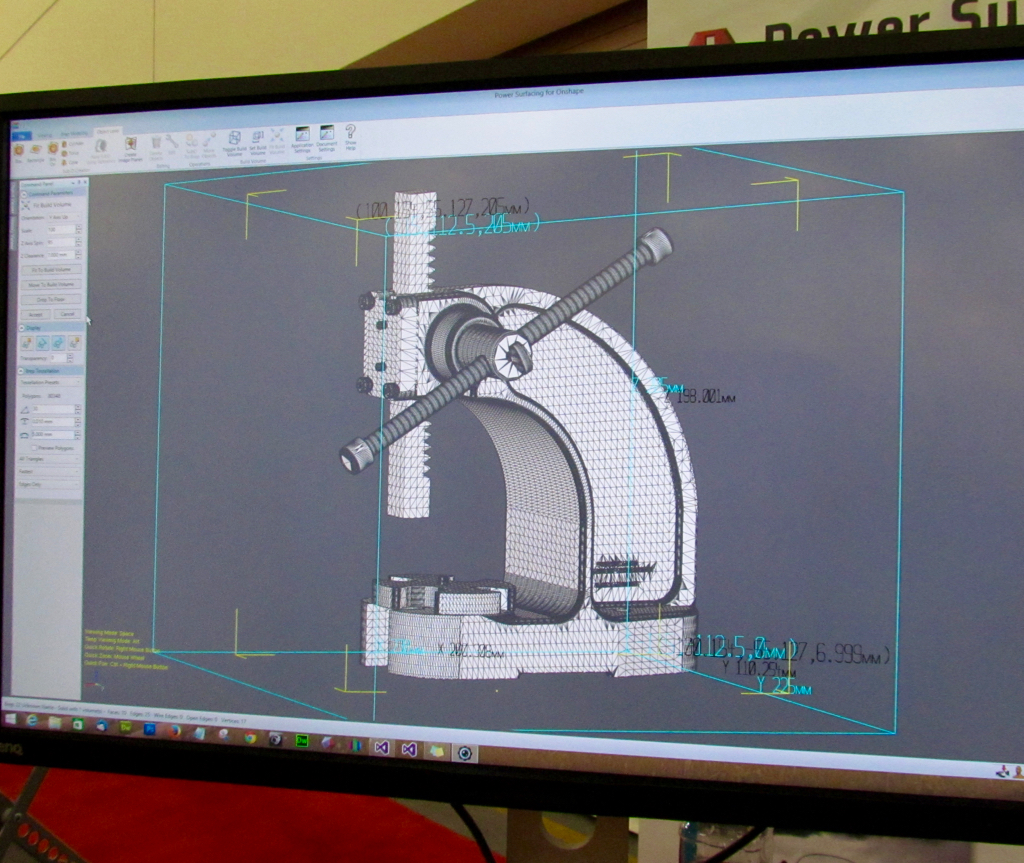

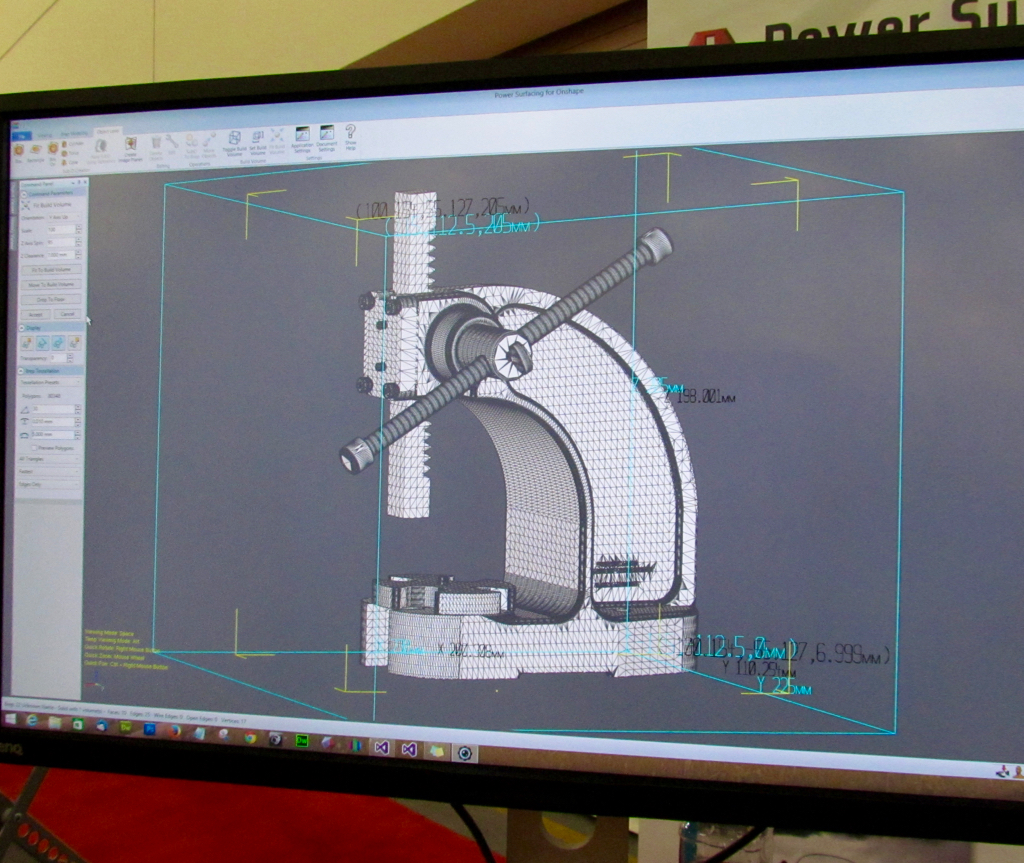

The software works by re-topologizing the 3D object described by the incoming STL. Once this shape is fully known, they apply their algorithms to optimize the STL.

STL, as you may know, is a representation of a 3D object made by a continuous arrangement of triangles, or a “mesh”. The problem arrives when 3D CAD programs produce meshes that are representative of the shape, but pathological in terms of individual triangles.

Some shapes are represented in STL by large numbers of very thin triangles. While the shape is indeed correct, this type of mesh can not only take longer for slicing programs to process, but also can actually confuse them to the point of incorrect slicing. This is what Cyborg3D is solving: it provides considerable controls for re-meshing an STL object to have “reasonable” triangles that are appropriate in number and shape.

You’re able to control the re-meshing to some degree by specifying some parameters, like the amount of subdivision, maximum triangle length, or angle of tessellation.

In some cases, this STL re-work could make the difference from a unsuccessful 3D print to a successful one.

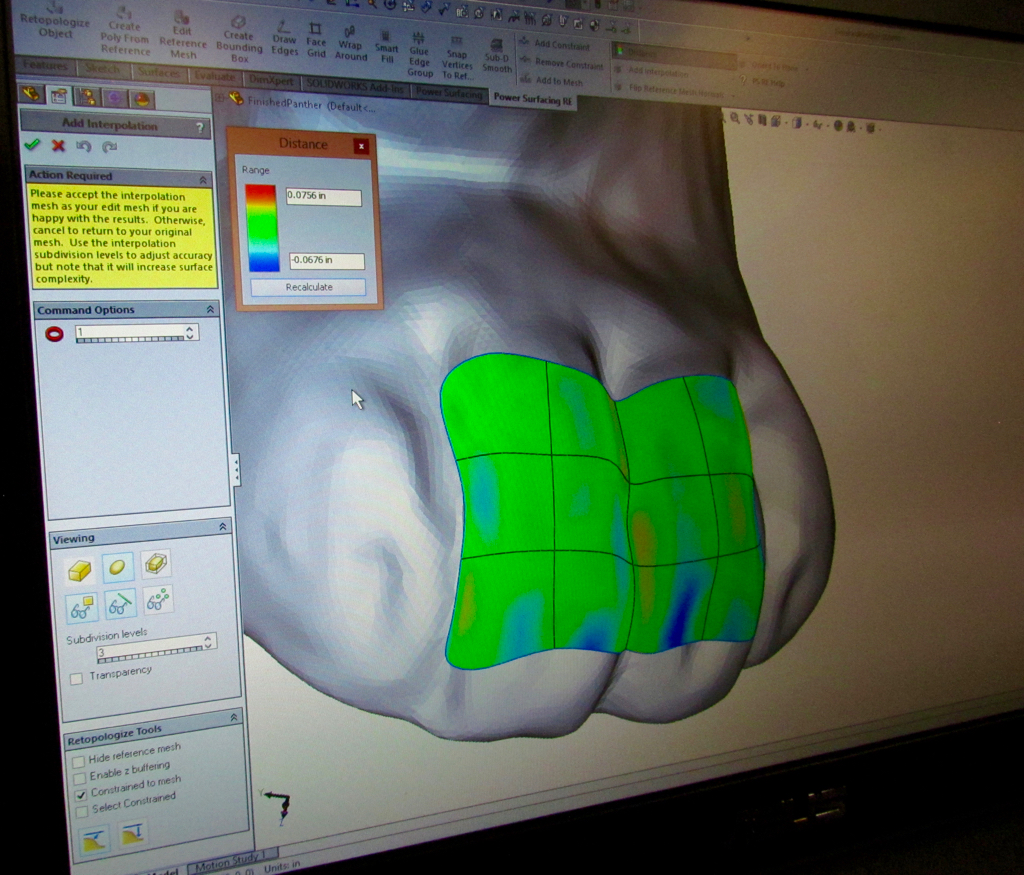

The Cyborg3D suite includes a variety of related utilities, such as Cyborg3D Scan2CAD, which accepts 3D scanned meshes and converts them into reverse-engineered CAD models. We’re told the betaversion of the reverse engineering tool will be out shortly, and will cost around USD$1,995.

Meanwhile the “regular” Cyborg3D CAD2Print retails for under USD$1,000.

Via Cyborg3D