Taiwan-based Sky-Tech Electronics announced the availability of a new, full RGB-color 3D printer based on powder technology.

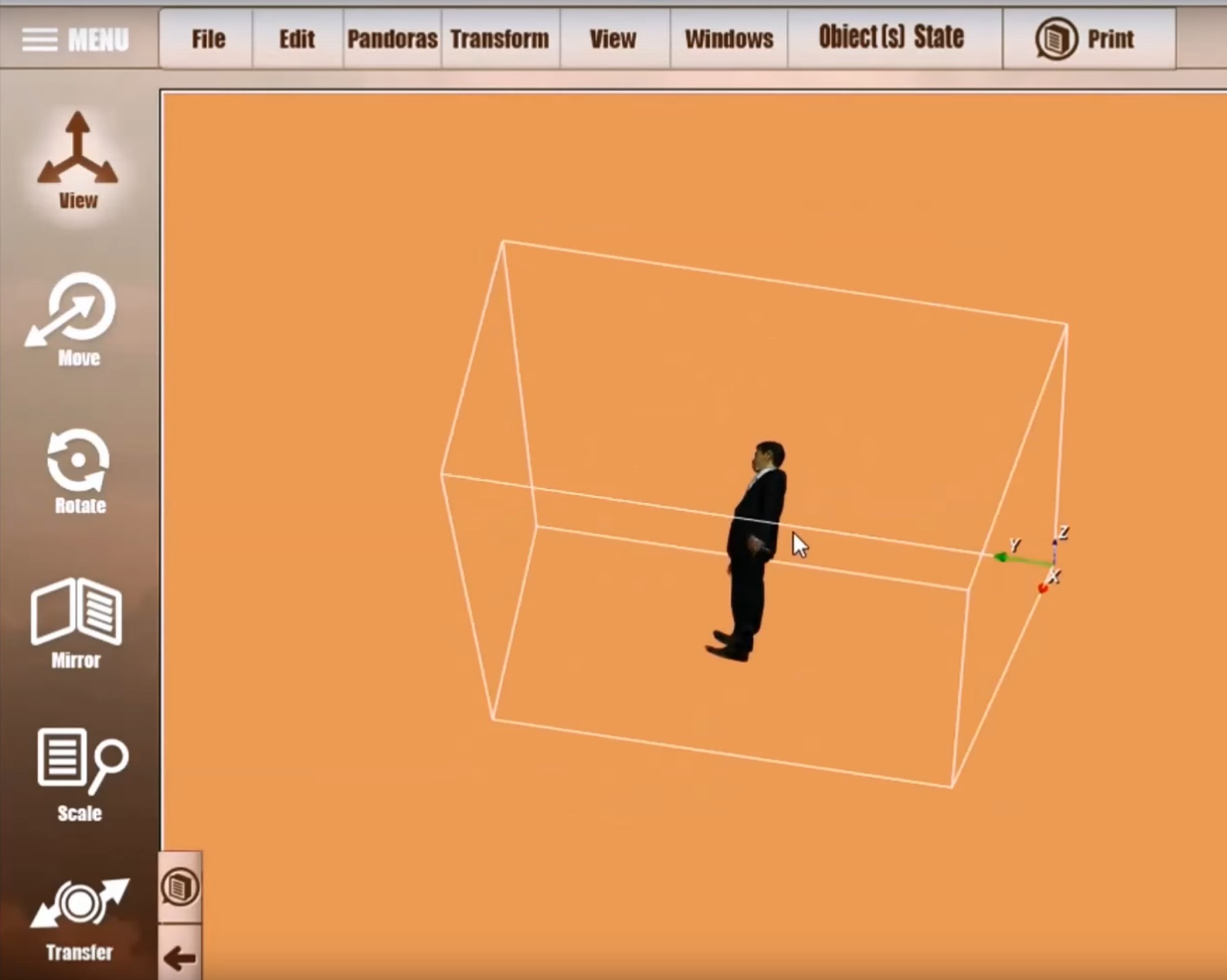

The 3DPandoras, as it is called, uses a combination of inkjet and powder to create fully colored 3D prints. Here’s how it works:

- A print chamber has a layer of gypsum powder applied

- An arm drags a traditional inkjet head over the flat layer of powder

- The inkjet head squirts tiny droplets of colored binder onto the powder layer’s surface, solidifying those portions (and that color is full RGB, not just “spot color”)

- The print bed drops slightly, and another layer of fresh powder is applied, to begin another layer

- The process repeats until the print completes

- The completed print is pulled out of the powder-filled chamber and finished with post-processing

There are huge advantages to this process aside from obtaining full color prints. The most significant is the ability to print any geometry without worrying about support materials or structures. That’s because the powder bed itself supports the entire model during printing. In fact, you have to dig the print out of the powder when complete. You can thus print a model in any orientation – and even fill the entire print volume with additional objects. You can even stack them on top of each other, something you simply cannot do with most 3D printers. This can make print jobs much more efficient, as you can print a large number of objects on each run.

The specifications are quite suitable:

- Minimum feature size: 0.08mm

- Layer thickness: 0.200 -> 0.080mm

- Build speed: 5.0-10.0mm per hour

- Build volume: 300 x 292 x 140mm

With this machine, you should be able to create very fine color prints, as you can see here. We are not aware of the price for this machine, but we believe it is less than the 3D Systems ProJet competing machine. We should be clear: this is not a hobby machine by any definition. It is a large unit, weighing 120 kg (265 lbs) and is larger than a fridge.

It is positioned as an alternative to 3D Systems’ line of color 3D printers, which are well-established and have been sold for many years. From what we can tell, the two machines use a very similar printing process, although the 3DPandoras has a smaller build volume, but faster printing due to a wider inkjet head.

While the 3DPandoras appears to be a very interesting option for full-color 3D printing, we have a couple of concerns:

The interior of the enclosed chamber seems to have a lot of exposed components. We know from experience that the interior of a 3D Systems machine can be subject to a lot of dust from the powder. We’re wondering how well the 3DPandoras will handle dust accumulation.

The 3DPandoras uses a similar post-processing method to 3D Systems’ early technology: dip the porous raw print into a resin to solidify it and bring out the colors. We’re wondering how strong the resulting objects can be, as there is no information on this aspect. Of course, objects created in powder processes such as this can never be as strong as plastic extrusion, but they can still be quite fragile. We want to know how fragile.

Finally, as this printing process appears extremely similar to 3D Systems’ approach, we’re wondering whether Sky-Tech could be viewed as violating any of 3D Systems’ patents on the process, which they acquired from ZCorp many years ago.

Regardless of the answers to our concerns, we are quite pleased to see yet another full-color 3D printing option to join 3D Systems and MCOR.

Via Sky-Tech