Carnegie Mellon researchers have worked out a way to successfully print “squishy” biological tissues, thus removing one of the key barriers to major bioprinting.

There are several big challenges to a future bioprinting world where arbitrary human tissues and organs can be readily 3D printed. Some, like the ability for living cells to remain alive during printing, and the ability to 3D print a wide variety of cells within a single print, are still being worked on by various groups.

But one other challenge may have been overcome: the ability to print very soft tissue structures in 3D. Previously, much of the 3D printed tissues were essentially 2D operations, with the thickness being determined by the ability of nutrients to penetrate and satisfy the living cells.

Previous methods of 3D depositing have involved using rigid skeletons of other material that eventually dissolves away, but for very soft prints, this may not be the right option.

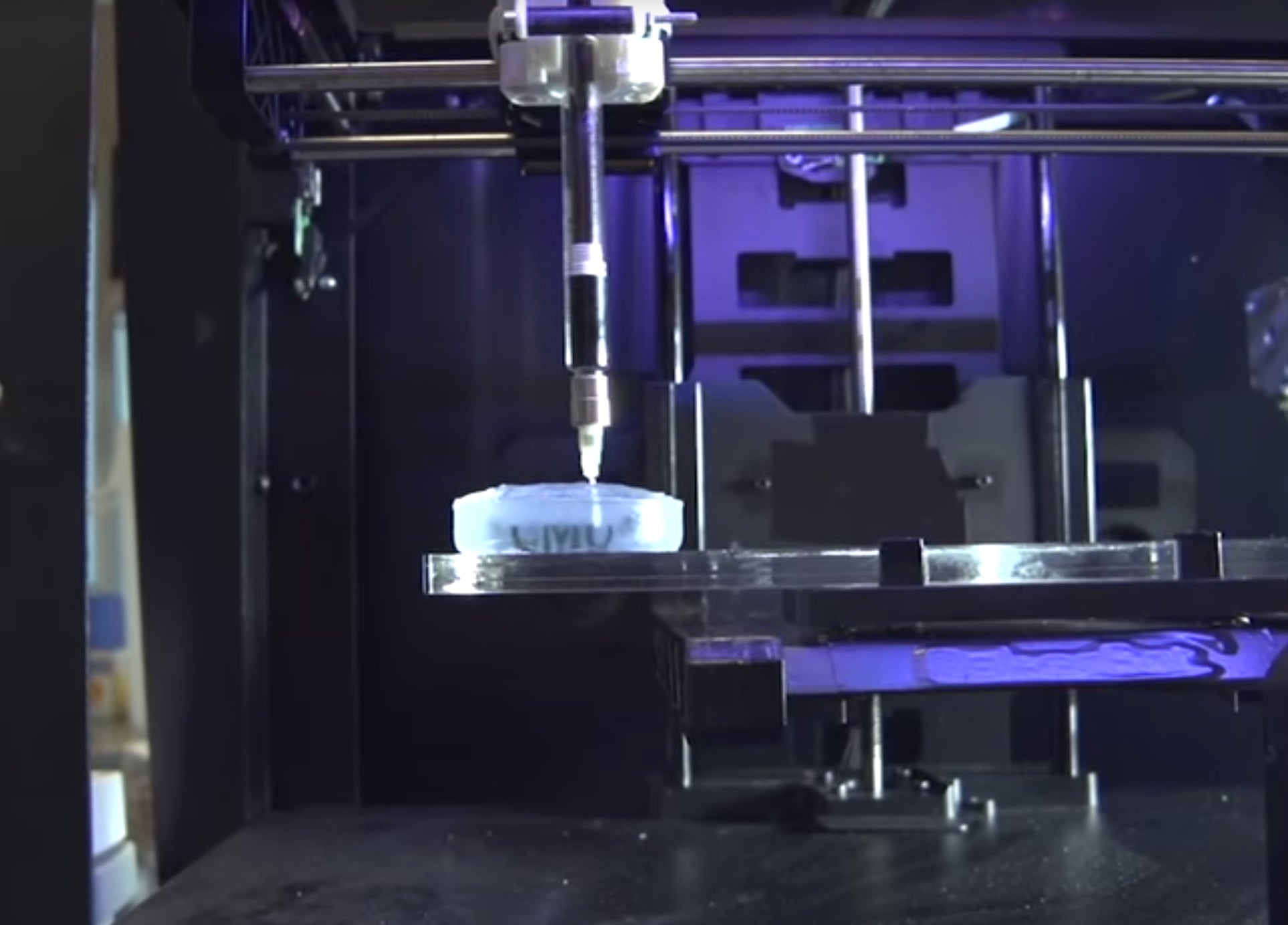

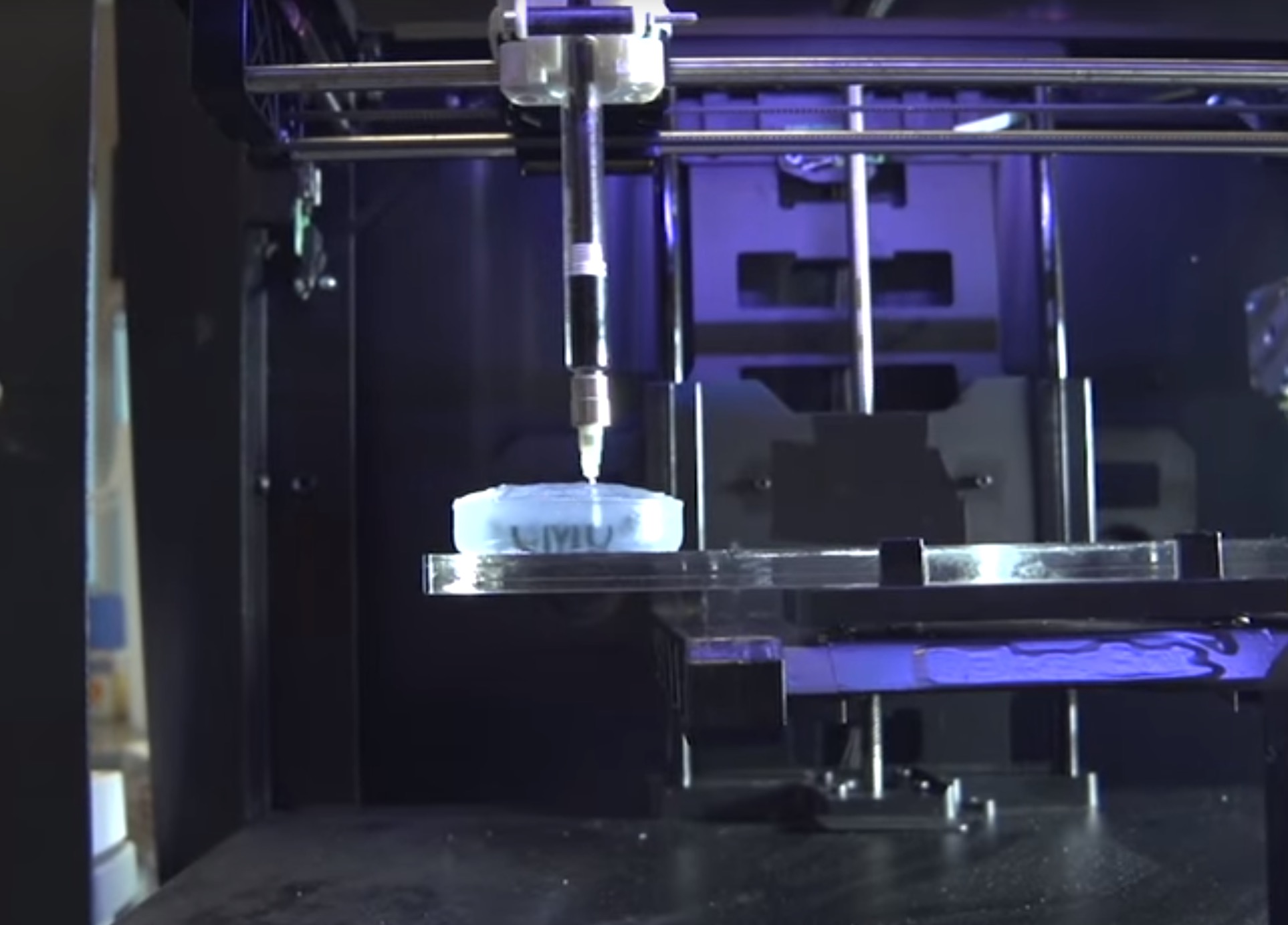

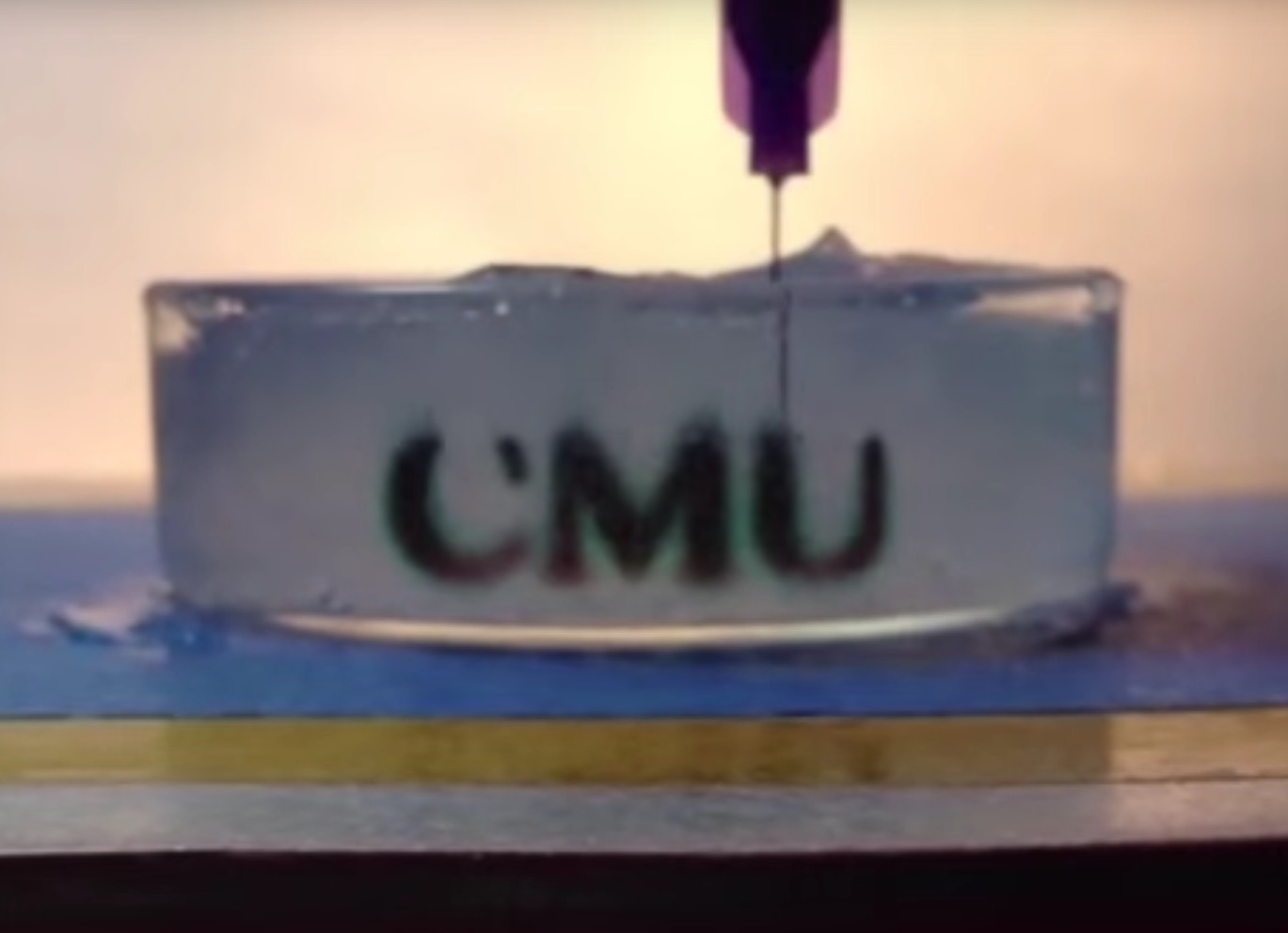

Now, researchers at CMU have developed a unique 3D printing process that could change things significantly. Here’s how it works: they deposit target cell material in a collagen slurry, which is semisolid at room temperatures. A needle-like extruder moves through the slurry, placing materials at target locations in 3D slurry space.

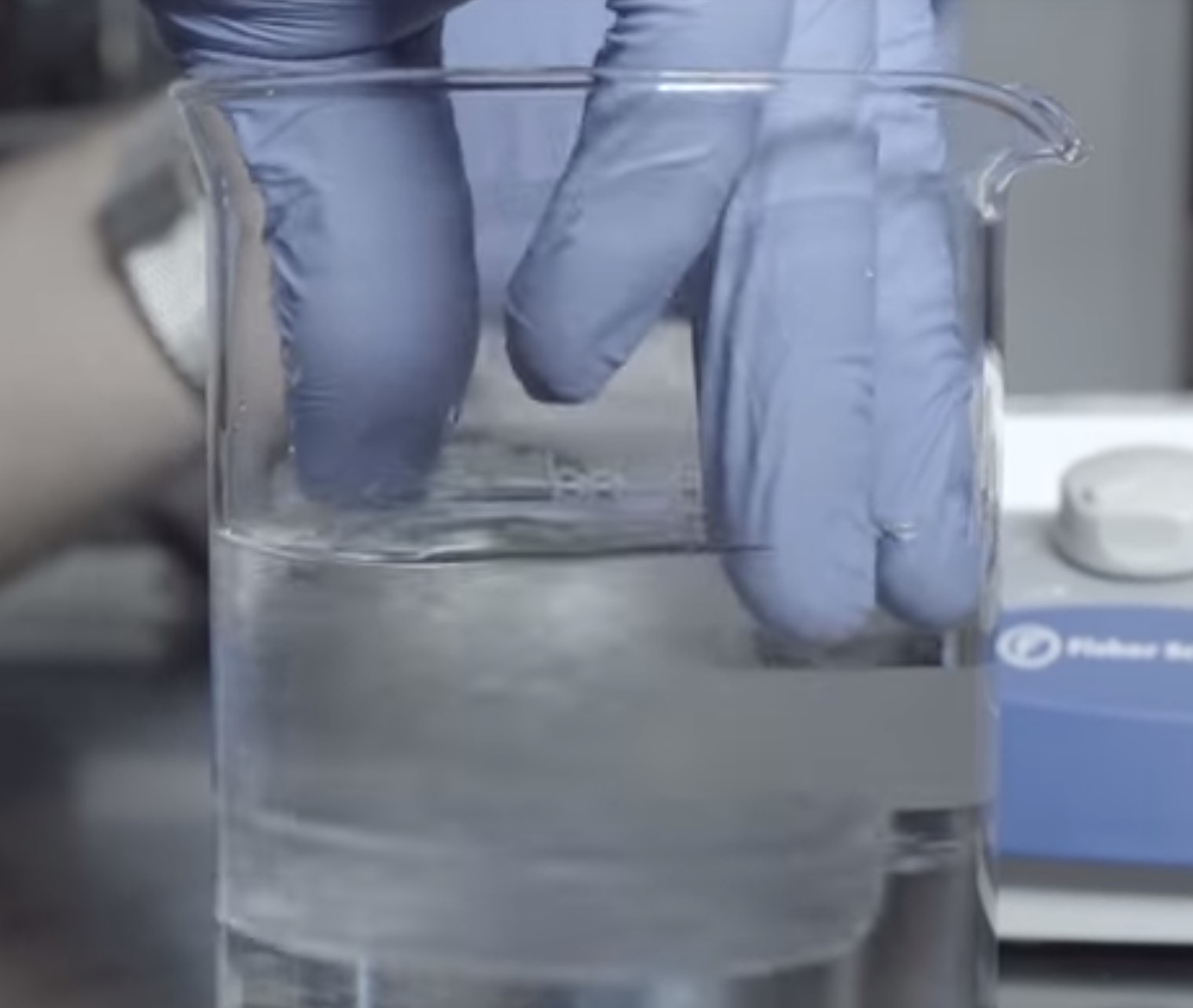

The best part is that the collagen melts away when heated to body temperatures. Objects printed in the collagen are then completed freed from the slurry, which is washed away with water. It’s very much like powder-based 3D printing methods, in which the powder provides inherent support structures for the entire model during printing.

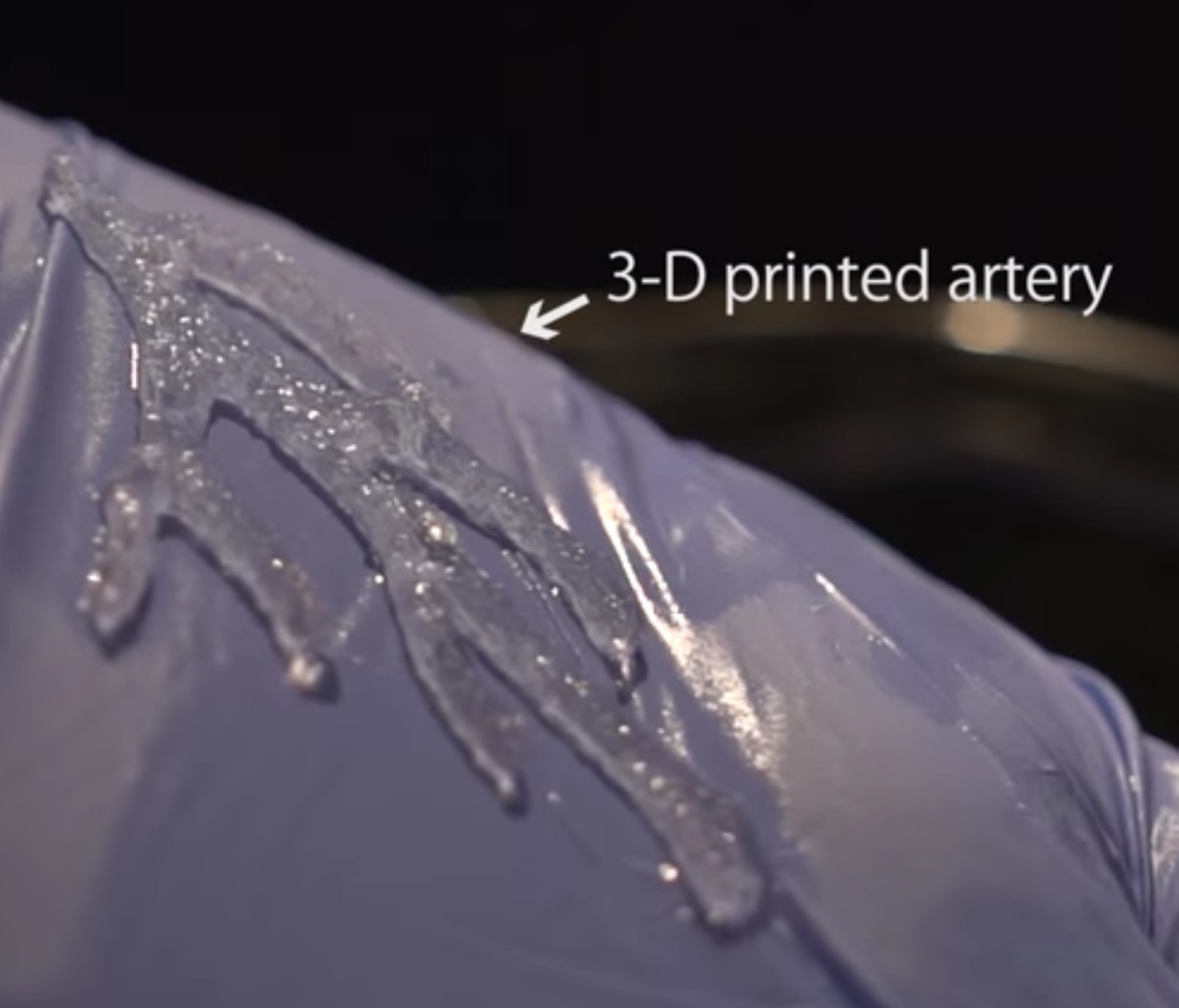

But the difference here is the the prints are bio-capable. Here you can see a prototype 3D printed artery, which actually functions when fluid is pumped through it.

The CMU team has printed a variety of prototype biological objects in squishy materials, such as a brain and chicken heart. These are actually mockups, as they contain no living cells and are simply done to demonstrate the ability to print very soft bio-material.

Their next step is, of course, to incorporate living cells into the process. At that point we may be well on the way to printing more complex functional body parts.

Via Science