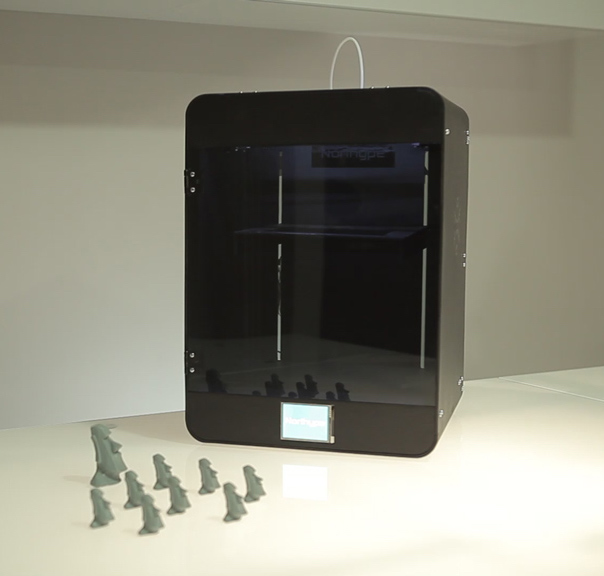

Another all-in-one making machine has emerged: the Northype Adam.

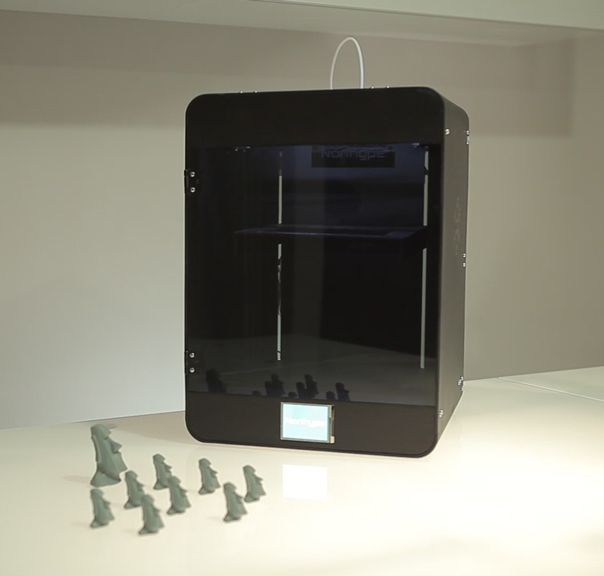

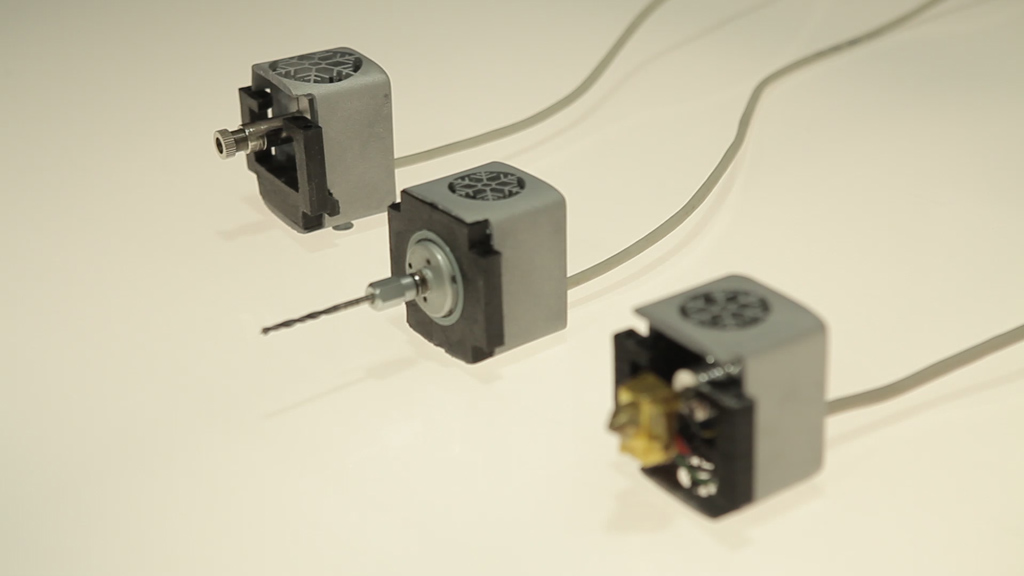

The Adam uses an approach that’s becoming increasingly common: leverage the mechanicals of a 3D printer to enable use of additional toolheads. The 3D printing extruder is replaced temporarily with other tools, but uses the same cartesian mechanicals for movement.

The Adam sports a standard 3D printing configuration including a 0.4mm nozzle, heated print surface, 1.75mm filament, color touch screen for operations, with a very generous build volume of 165 x 165 x 275mm.

But the magic happens when you swap the 3D printing extruder for alternative tools. So far, Northype has provided the Adam with the ability to install three:

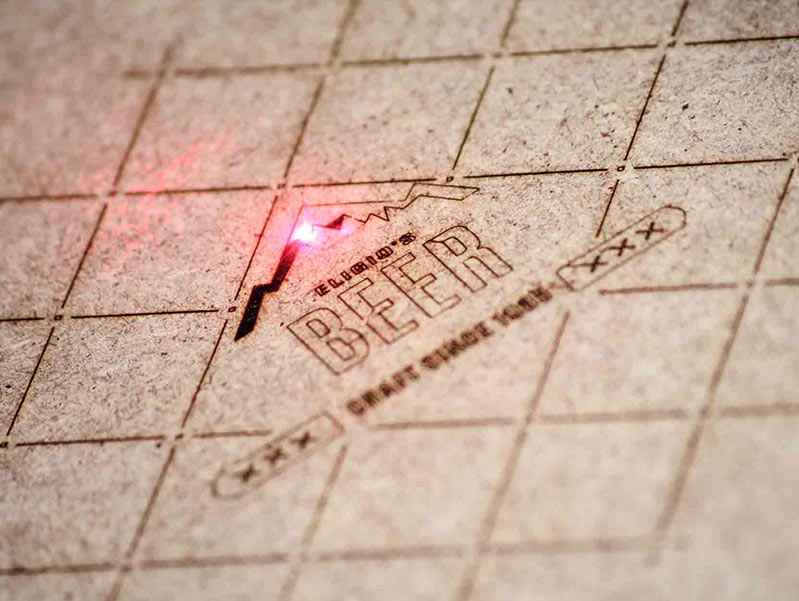

A low-power laser enables 2D engraving and cutting of light materials, including paper and films. Northype says the laser is able to engrave “plywood, polystyrene, MDF and leather”.

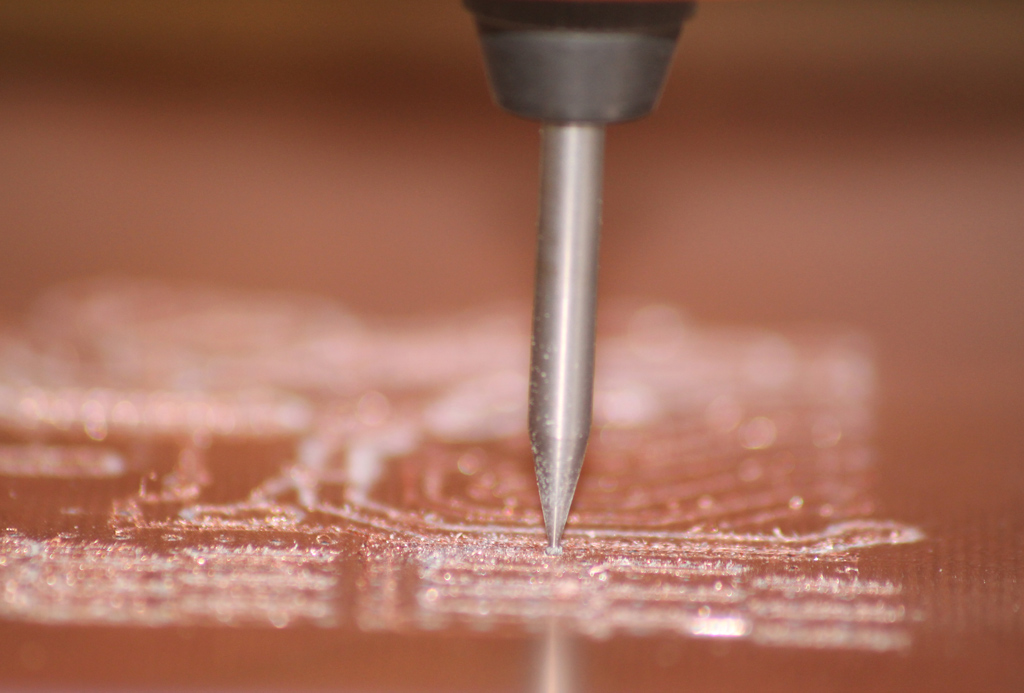

A milling toolhead enables 3-axis milling. This means you can carve out custom electronic circuit boards, as well as milling 2D and 3D shapes from light materials. Note that this will be a 3-axis mill, so you cannot mill any overhangs.

Finally, the Adam is also equipped to perform 3D scanning.

Apparently they are already working on a new toolhead that will enable 3D printing of paste materials. However, it is not yet ready but might appear as a stretch goal of their Kickstarter.

The Adam is not yet available; the company says they will be launching a Kickstarter campaign within a few weeks, when we will be able to determine the final pricing for the Adam. We do know, however, that the early-bird price for the Adam will be a rock-bottom price of only €899 (USD$1020). That’s not a bad price for a machine that performs four different functions!

Via Northype