Poland-based Sinterit is set to announce the Lisa, a low-cost sintering 3D printer.

The device will be displayed at Euromold later this month, but it will be available for purchase on their website tomorrow.

But first, let’s explain a bit more about this very interesting device. It’s a sintering printer, meaning it fuses powder together in layers to form a solid object, layer by layer. It’s technology that is similar to the SLS machines of 3D Systems or EOS, but it appears at a much lower price point.

The machine uses a powder, shown here. It’s polyamide, similar to nylon, that should produce very strong parts. Specifically, the material used is Black PA12. They’re expecting to release additional materials soon.

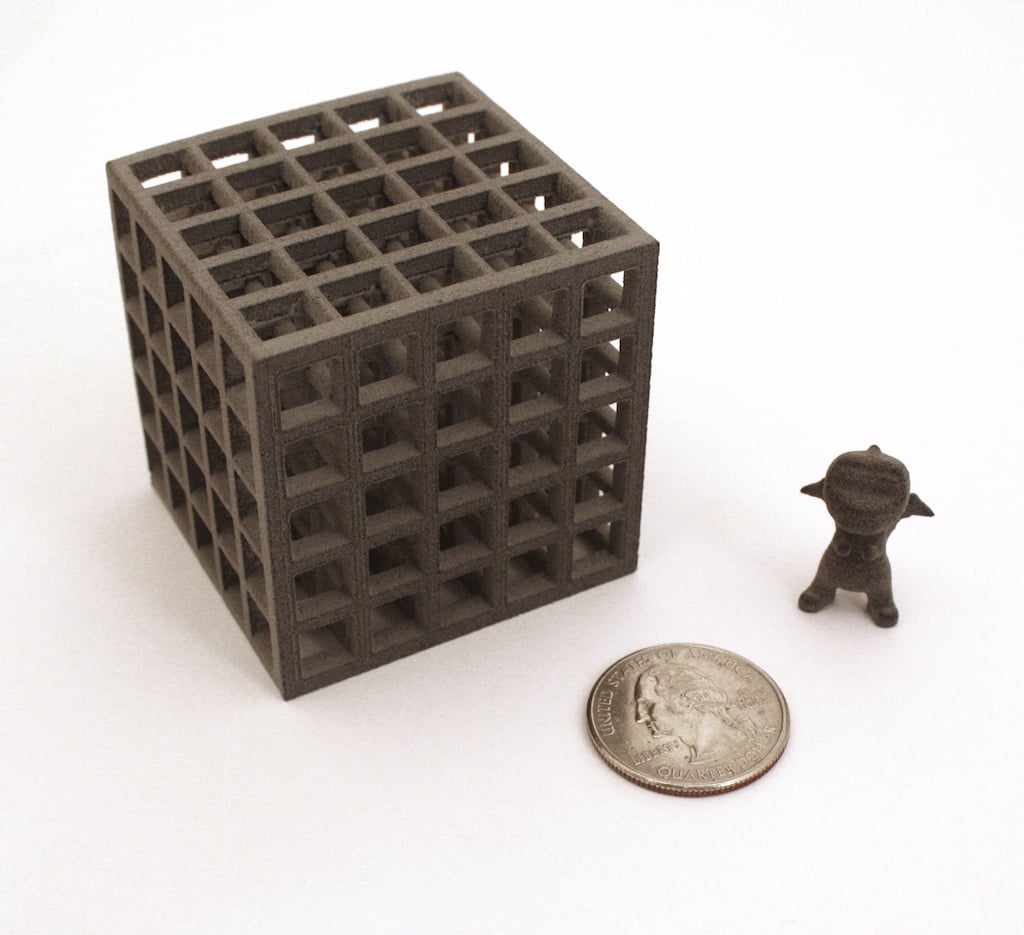

The Lisa’s print volume is a healthy 150 x 200 x 150mm, smaller than some more expensive industrial 3D printers, but certainly sufficient to print many objects. The minimum layer size is 0.06mm, which is also quite fine. At this resolution, objects should almost have no visible layer lines.

The powder process has a very useful side effect: as no support material is required (the surrounding unfused powder does that for you by default), you can stack many objects into a single print job. In fact, you can even fill the build volume entirely, right up to the top, as this is the most efficient way to use the machine.

The retail price of the Sinterit Lisa will be only USD$8,000. However, there’s a very special deal available:

We offer Sinterit Lisa for 5000$ to the first five persons that will place their orders before the printer’s appearance at Euromold. The next five clients will be able to buy it for 6000$ while the last discounted pre-launch series will come for 7000$.

We have some questions about the logistics of handling the fine PA12 powder, because if the machine isn’t designed properly, you could easily get a very big powdery mess in your workshop. However, they say there’s a “removable overflow bin”, so we’re hopeful.

If this machine proves effective, it could be a game changer, as many print services use the higher-end equipment for their massive print jobs. It’s possible this machine, if supplied in multiples, could do the job of a single industrial quality machine at a lower price. 3D Print service companies might want to acquire one of these models to do some testing.

Via Sinterit