NASA and America Makes’ contest to develop ideas for a 3D printed space habitat has converged on 30 finalists.

The contest, announced earlier this year, required entrants to develop the fundamental technologies necessary to manufacture an off-world habitat using mission recycled materials and/or local indigenous materials. The idea is to house a fictional astronaut team of four on distant Mars. Maybe these particular designs won’t make it off-world, but the ideas and techniques created during the contest will surely help that happen.

The first level of the competition involves the design, while subsequent levels will investigate the feasibility of manufacture using indigenous materials and actual fabrication.

A cash prize pool of USD$50,000 will be divided between three finalists at this year’s NYC Makerfaire, evidently selected from the thirty finalists.

We’re not going to show you all thirty of the finalists, that’s more than we can do. But we can show you three that caught our interest.

At top we see an image of team GAMMA’s entry, which involves a combination of 3D printing and inflated structures:

A semi-autonomous multi-robot regolith additive manufacturing (RAM) system is used to create a protective in situ shield around a modular inflatable hab.

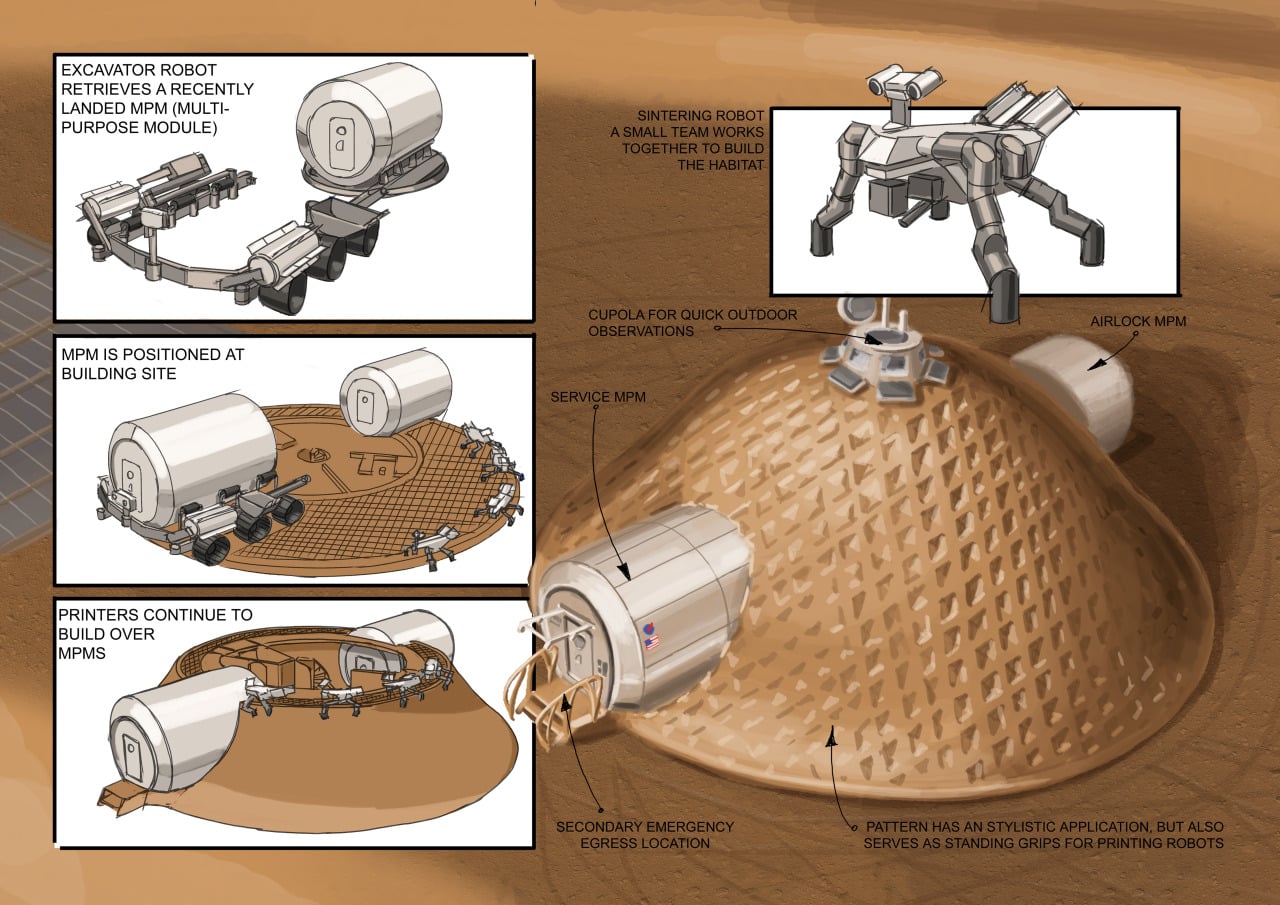

Team MASS’s entry involves a familiar 3D printing process:

Team MASS is developing a 3D printed Martian habitat using laser sintered regolith. A combination of 3D printed structures using in situ resources and hard structures transported from Earth will be assembled by a swam of robots. Our large earth-moving robots will excavate regolith and move structures into position while legged robots will laser sinter regolith to create the main habitat dome.

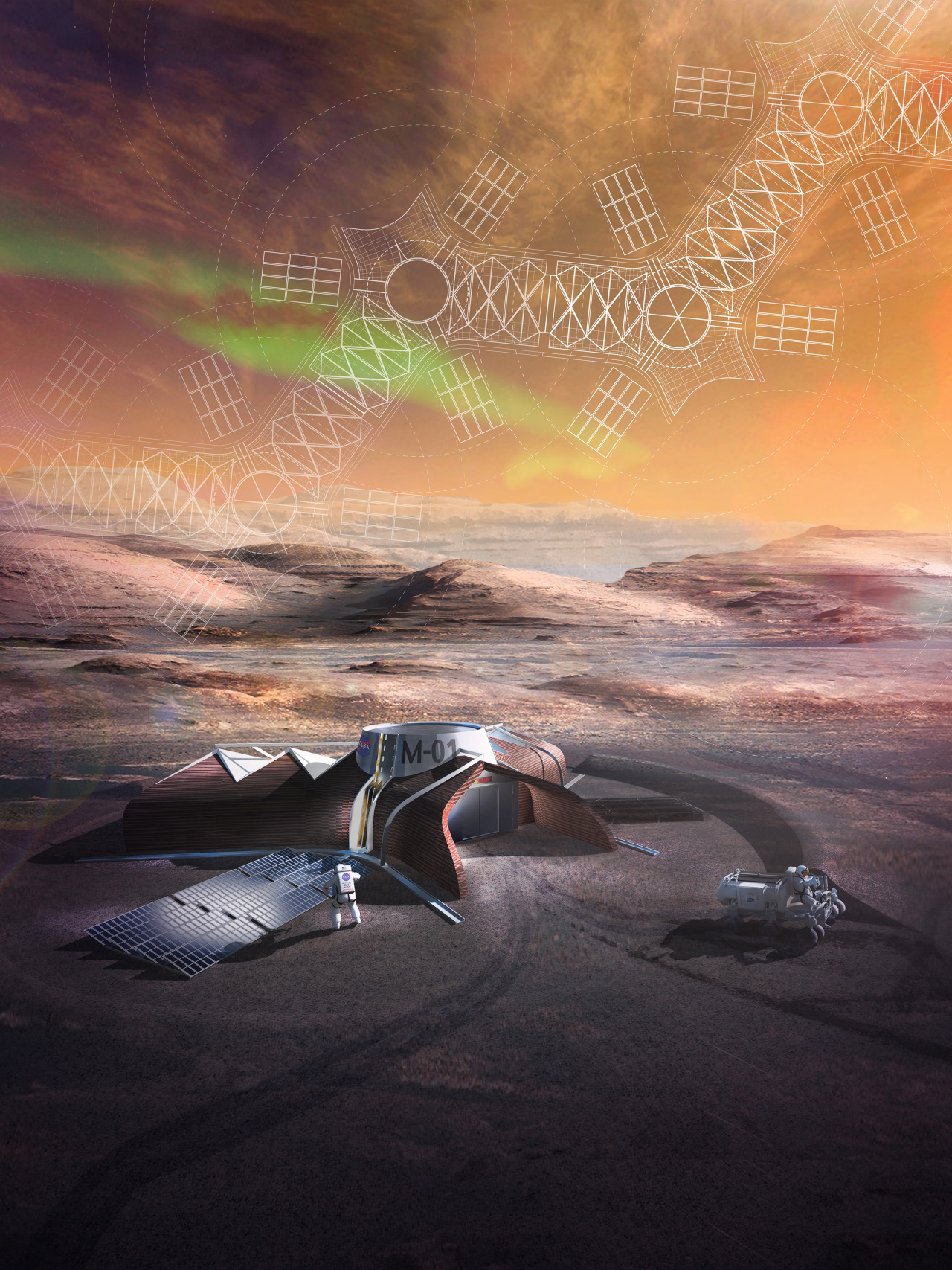

Here we see PARALLAX’s “Radicle”:

Our design consists of a two-part system of construction based on a three-armed geometry in response to the logistical challenges of building a safe and comfortable habitat for living and working on Mars. Part one consists of pre-fabricated foldable envelopes that deploy from the landing capsule when pressurized to earth-like atmospheric conditions. One wing for living and one wing for working, they are joined by the landing capsule that doubles as an intermediary airlock between the two wings and the Martian environment. Part two is a cementitious shell 3D-printed from local Martian resources. The shell both insulates against extreme temperatures as well as shields the inner envelope of the habitat from radiation, sandstorms and debris.

All the entries are quite different and at first glance appear practical, although that factor will be evaluated as the contest proceeds. We’re obviously a very long way to making 3D printed habitats a reality, but the first steps on such a journey are always found by brainstorming up concepts like these. Good luck to all finalists!

Via 3DPChallenge