MIT recently reported that they’ve created a 3D printer that fabricates objects from 10 different materials at the same time, using a combination of “machine vision” and 3D scanning.

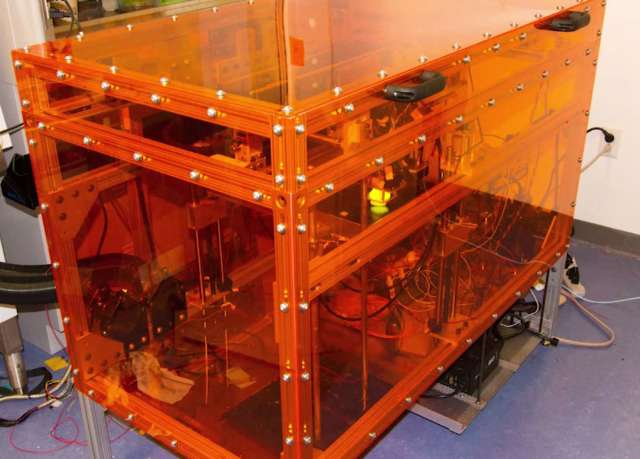

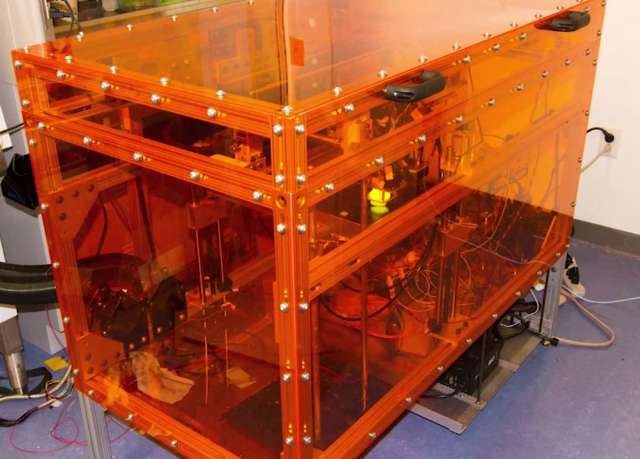

Researchers outlined the features of the new 3D printer, which was created at MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL), in a paper, entitled MultiFab: A Machine Vision Assisted Platform for Multi-material 3D Printing, which was accepted at this year’s SIGGRAPH computer graphics conference.

“Platform is first to use machine vision to self-correct and embed components, saving users money, time and energy,” according to MIT.

Besides being able to print in 10 different materials, the MultiFab machine, as it’s called, can self-calibrate and self-correct by using a feedback loop that 3D scans to find errors and generate what they call “correction masks.” Also unique to the MultiFab is its ability to embed complex components such as sensors and circuits directly onto an object. According to the paper, this means it can produce a finished product with moving parts and electrical components in one print job.

According to research engineer Javier Ramos, “The platform opens up new possibilities for manufacturing, giving researchers and hobbyists alike the power to create objects that have previously been difficult or even impossible to print.” Javier coauthored the paper with Professor Wojciech Matusik’s Computational Fabrication Group and the research was partially enabled by a grant from MIT’s Deshpande Center for Technological Innovation.

So far, the team has 3D printed smart phone cases (directly around the smartphone itself) and light-emitting diode lenses, and they have plans to print while in betting motors, actuators and other components included in the manufacturing of more advanced electronics. The printer was built using inexpensive components that cost about $7,000.

Read more at ENGINEERING.com