Annie Wang and Zach Simkin of Senvol presented some interesting logic regarding how companies should consider organizing their 3D printing infrastructure for optimum efficiency.

The objective is to obtain 3D printed parts for company use at the most effective cost, but Wang proposes that geography is a major factor contributing to these costs, regardless of the actual 3D printing technology used. Even if identical technologies are used, part costs will be quite different between printing locations.

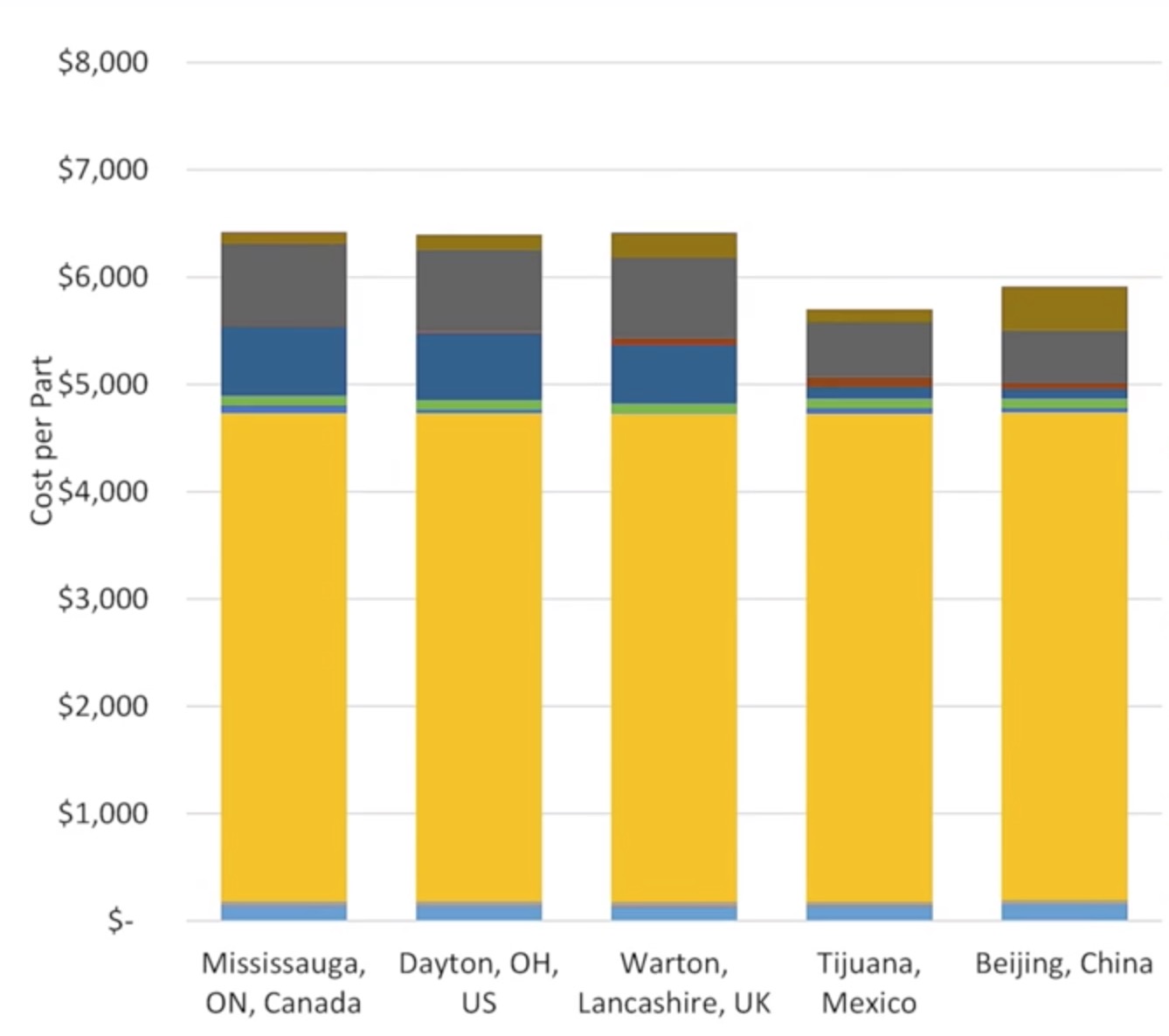

They point out that the cost of producing a 3D printing part includes factors well beyond the cost of the printer and material, such as labor rates, energy costs, floor space and other costs. In fact, their analysis is quite detailed and includes not only the major cost elements, but also the amortized costs of associated equipment over their likely operational lifetimes.

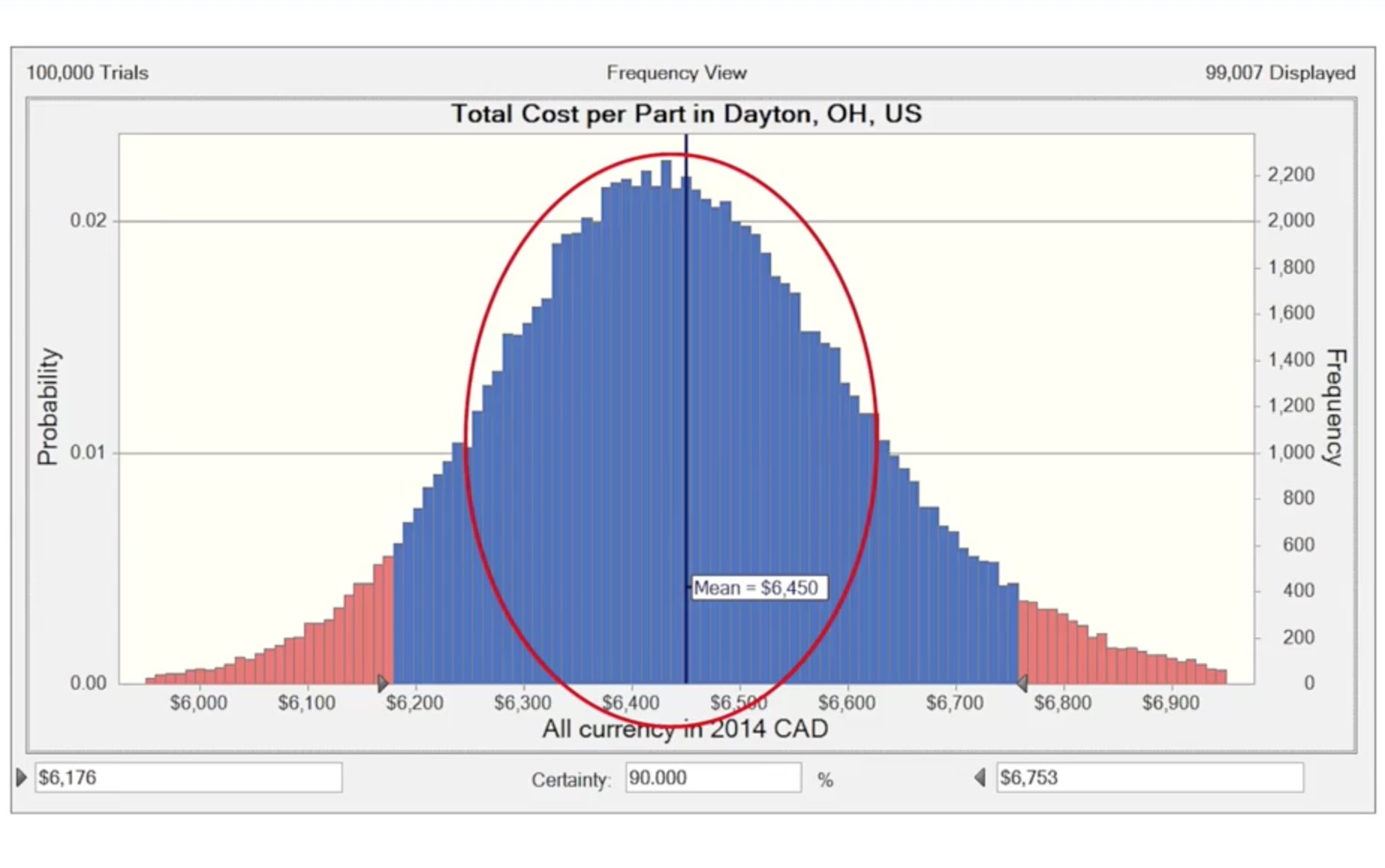

To make the case, Senvol portrays an analysis of five scenarios the company provided to the Government of Canada. The analysis involved setting up an identically-equipped 3D printing operation in five locations: Canada, China, Mexico, USA and the UK. By combining the underlying charges that comprise the full and total cost of 3D printing in each location, they were able to calculate the estimated cost of producing parts at each location to a reasonable level of probability. You can see here a graph of such a cost estimate.

It turns out in the specific analysis shown, that Mexico turned out to be the most cost effective location. However, what we find interesting is that Senvol has developed a “Total Cost of Printing” equation, something that can be experimented with by predicting how some of the factors may change over time, if one were to set up a production center in any of the measured locations.

This is the type of analysis that any company should perform if considering not only building their own 3D printing production process, whether their own or outsourced to others. We’d strongly recommend companies contact Senvol to assist with such an analysis.

Via YouTube