This week’s selection is the very unusual VOXEL chair by designer Joshua Sellini.

The VOXEL is the end result of a design exploration by Sellini, who considered a variety of design and construction approaches, including laser cutting, CNC machining and more. The end result is an unusual chair made from a combination of 3D printing and conventional woodworking processes.

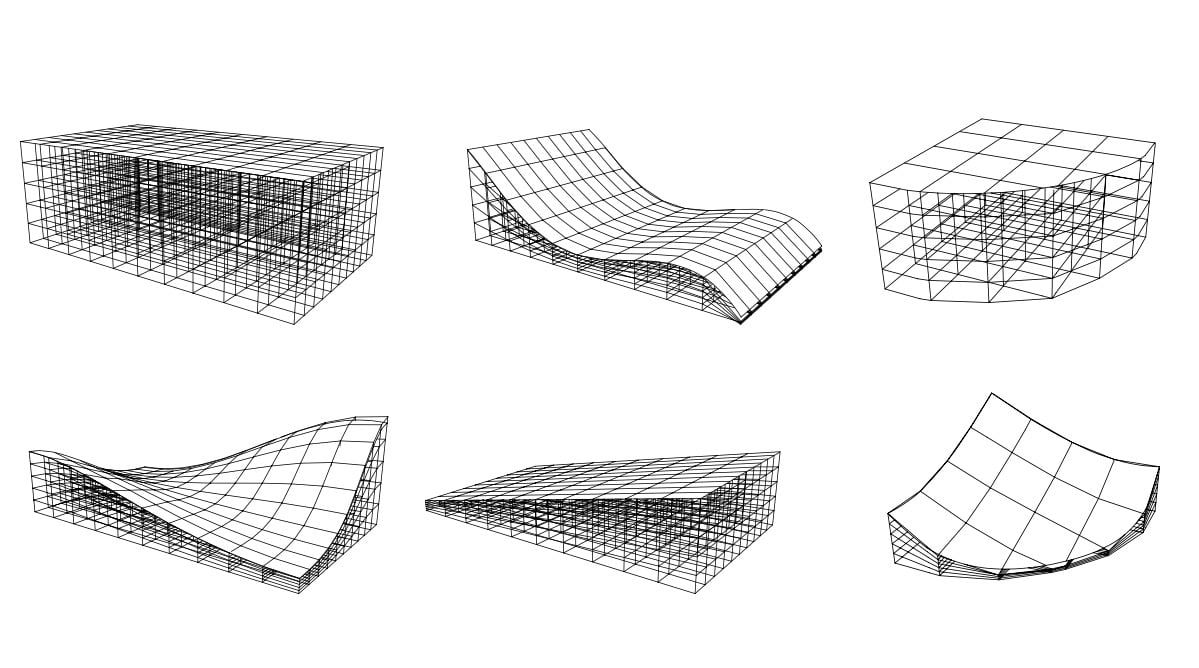

Here we see the concept behind the chair: local deformations can adapt the surface to a variety of dynamic shapes. However, when implementing the concept, Sellini ran into a couple of key issues:

3D printing flexible elements was possible, but when compressed they tended to expand outwards, making the interior cells squish against neighbors. The brilliant solution was to use what’s called “Auxetics”. These are shapes that when compressed, actually become thinner. Sellini then designed cells to leverage this effect.

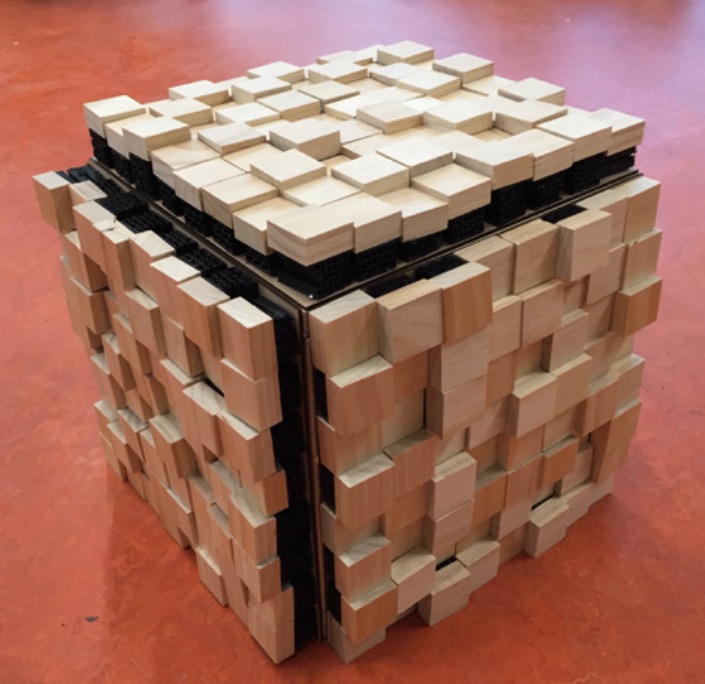

The second major issue was print time. To properly implement the concept using mostly flexible 3D printed parts, he would have expected to be 3D printing for literally months! A compromise was arrived at by printing a combination of flexible elements with rigid pieces made conventionally, as shown here.

After printing the required complement of pieces with 3-5 3D printers running simultaneously over a week, Sellini then prepared the required wooden pieces using normal woodworking techniques.

Assembly revealed the final design, a chair like no other.