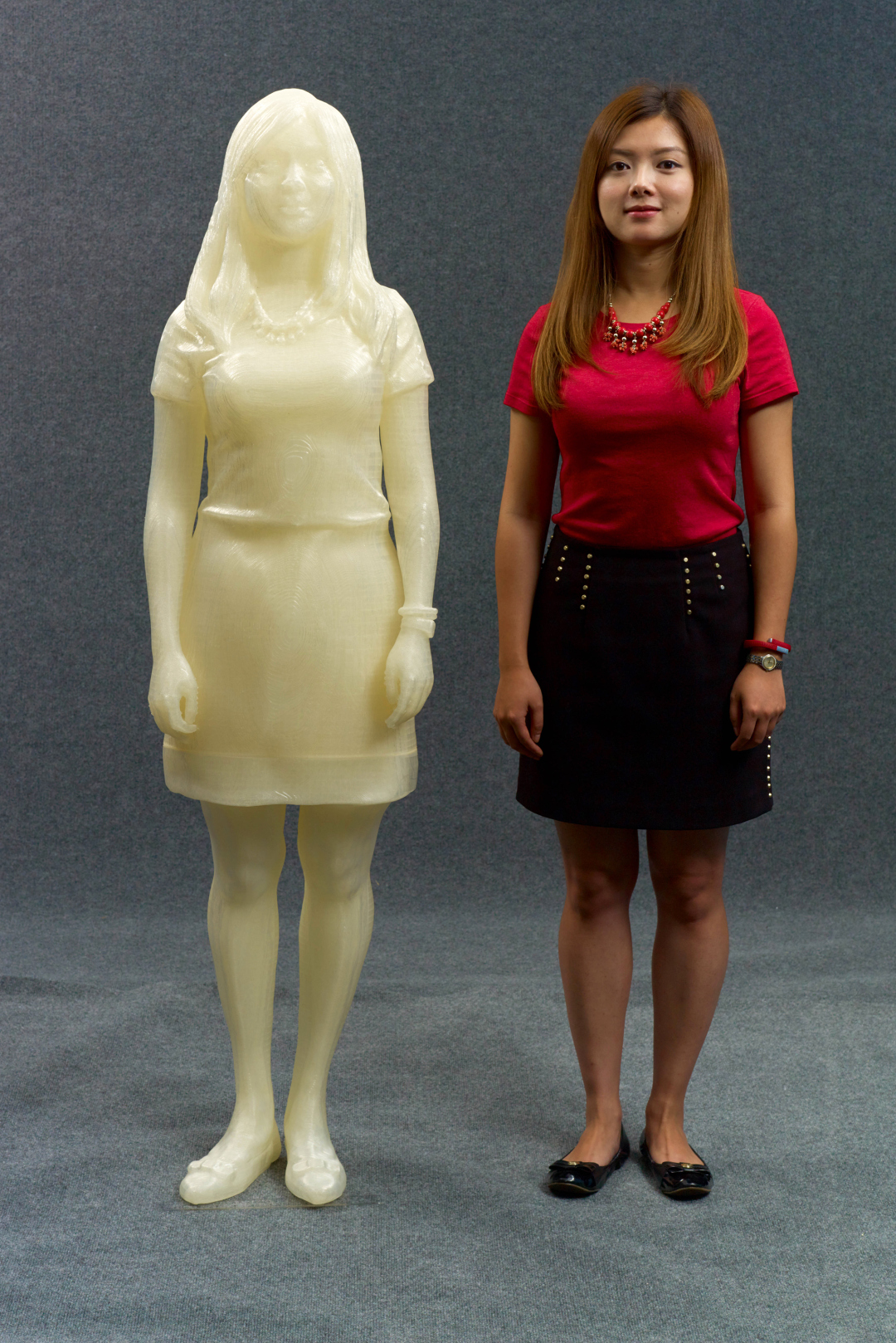

3DP Unlimited manufactures some very large 3D printers, and now they’ve demonstrated exactly how large by 3D printing their own staff!

3DP Unlimited Marketing Communications Specialist and Fabbaloo friend Marketing Communications Specialist was 3D scanned and then printed in two pieces on 3DP Unlimited’s 3DP1000, which has a build volume of 1000 x 1000 x 500mm.

Ms. Lu is by no means the tallest person we’ve met, but the print is still quite massive. It’s also larger than the build volume of the 3DP1000, so Ms. Lu (or rather her 3D model) had to be sectioned in two pieces that were printed separately.

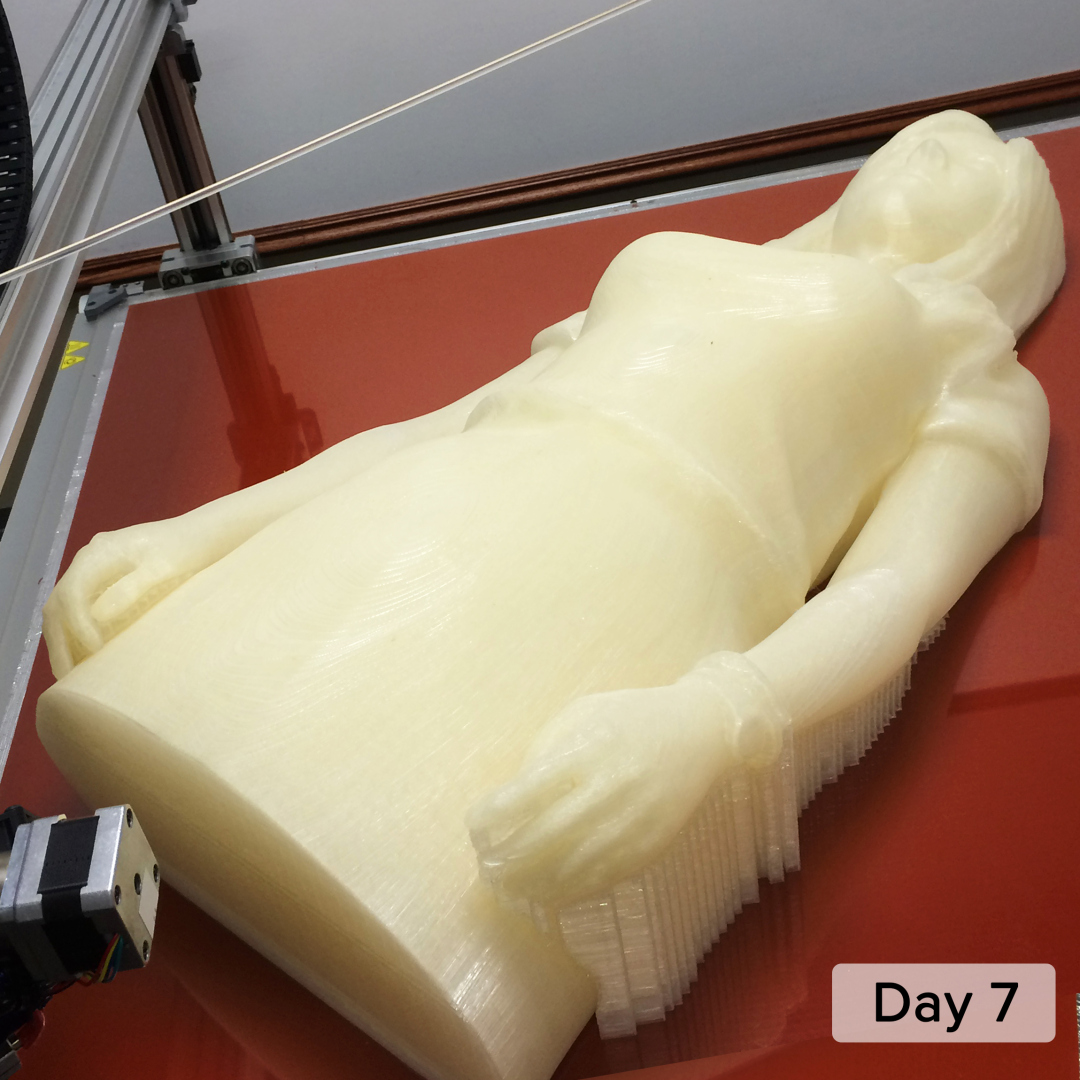

Here you can see their technique: laying the model down to leverage the full diagonal dimensions of the 3DP1000, which is actually MORE than 1000mm when measured diagonally.

Aside: this diagonal printing technique works on a 3D printer of ANY size. We’ll talk more about this another time.

3DP Unlimited says the project took 168 hours seven days to complete each half, which were then glued together.

We’re not certain of the cost of printing such a large model, but there are clearly several kilograms of plastic used here, but we’d guess around 6kg were used. At a cost of USD$20 per kg, that implies a cost of something over USD$100 to print this huge model, at least for material. That’s not very expensive for such a massive print!

But you can only do that if you have a large format 3D printer handy, which you can obtain from 3DP Unlimited.

Via 3DP Unlimited

Fabbaloo founder/editor Kerry Stevenson, a.k.a. “General Fabb” has been writing and exploring 3D printing with Fabbaloo since 2007.