The number of very large plastic-extrusion technology 3D printers is increasing. Today we’re looking at the Cosine AdditiveMachine1, which definitely qualifies for that list.

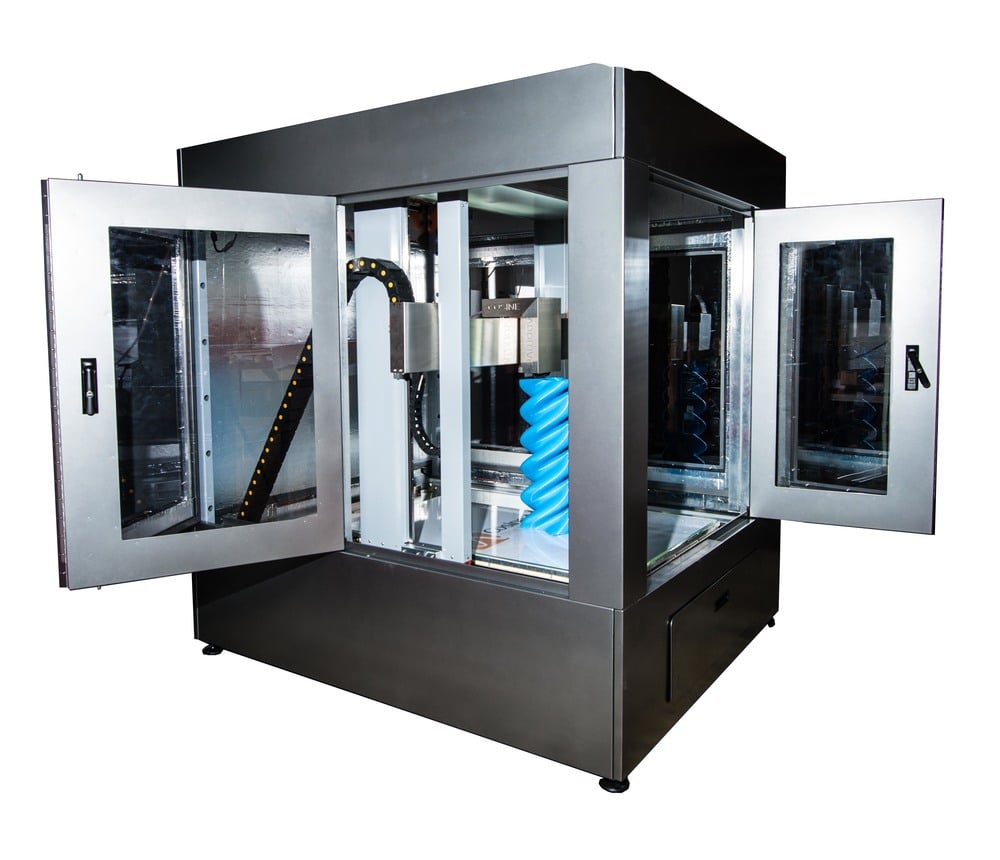

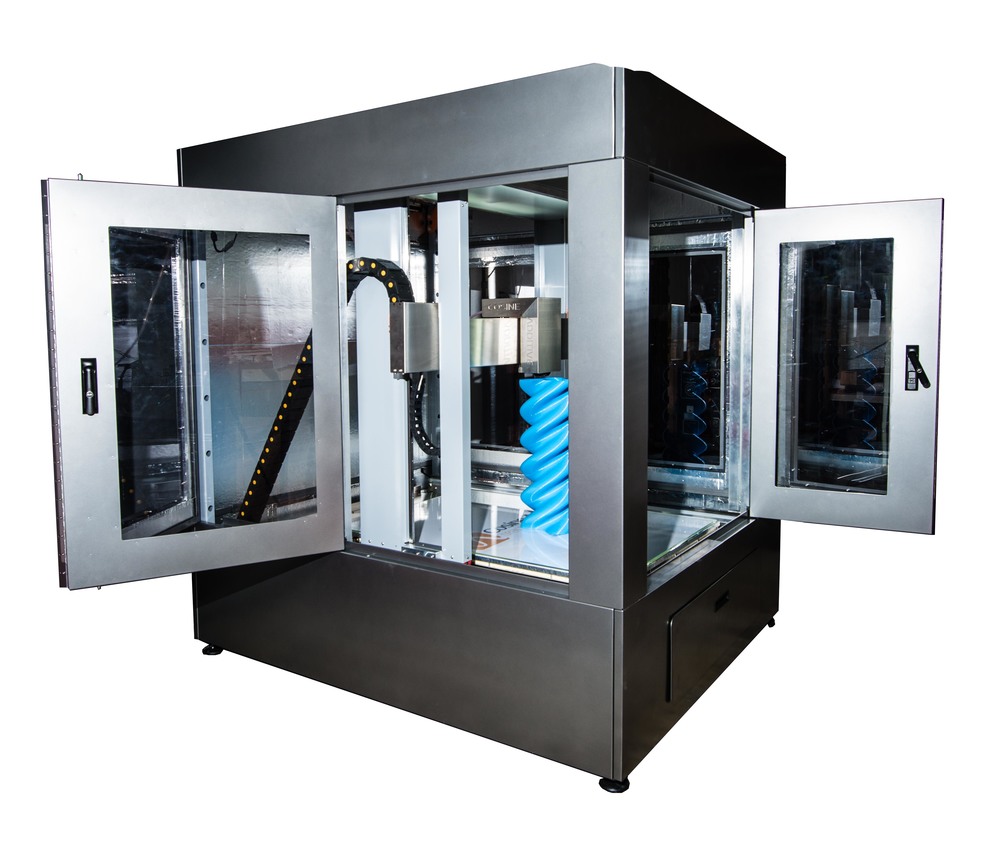

Cosine Additive is a large-format 3D printer with a difference. Like other large-format options, it has a massive build volume of 1100 x 850 x 900mm and can print layers as small as 0.100mm. It’s heated bed is standard for machines of this size, but it does have a completely enclosed build chamber to ensure quality prints. Here we see a 52-hour polycarbonate print.

The difference is in the hot end, which can reach temperatures of up to 450C. This means this machine can print materials beyond the usual ABS and PLA. In fact, most lower-cost large format 3D printers typically print only PLA to minimize warping. However, the AdditiveMachine1’s heated bed and enclosed chamber can overcome that limitation. Thus, they’ve enabled the machine to also 3D print these materials:

- Polycarbonate

- Nylon

- PBT

- HIPS

- PETG

- Acetal

- PVA

Even better, the machine is also capable of handling filaments with these additives mixed into filaments:

- Carbon fiber, chopped

- Carbon fiber, continuous

- Carbon black, ESD

- Glass fiber

- Stainless steel powder

- Bronze powder

- Mica

- Glass spheres

And it’s quite likely the machine could handle many more similar additives, as the company probably haven’t been able to test everything. They say it’s an “open materials platform”, meaning you can try any reasonable material without the need for proprietary cartridges.

The Cosine Additive machine also is quite speedy. By equipping it with the 1.5mm nozzle, it can print as much as 3.5 kg (8 lbs) of material per day. They’ve also been experimenting with incredibly huge 50 pound (25 kg) filament spools, which would enable unattended 3D printing for literally days.

This creates a powerful machine that can be used for many industrial purposes. Here we see an example print where they’ve created a mold for a small rocket fairing using a new carbon fiber-polycarbonate filament. The resulting 12-hour print is a very strong mold that can be used for production purposes.

The company does not publish list prices for these machines, as they appear to custom build them to order. However, based on the machine’s functionality, we suspect the pricing would be several tens of thousands of USD$.

The price is likely sufficiently low to attract manufacturers who might otherwise be unable to afford to use 3D printing at this scale.

It may be that Cosine Additive’s machine could open up a whole new world of products for small-sized manufacturers.

Via Cosine Additive