We spoke with Element Robot’s CEO, Chris Walker, about their cloud-based 3D print management system.

You probably haven’t heard much – if anything – about Skyforge as their marketing presence is “under the radar”, according to CEO Walker. He says they’ve been busy building and refining the system first so that they don’t have to deliver on “wild promises”. We think that’s a good strategy.

But what is Skyforge? It’s a “3D printer management platform” that provides these three functions:

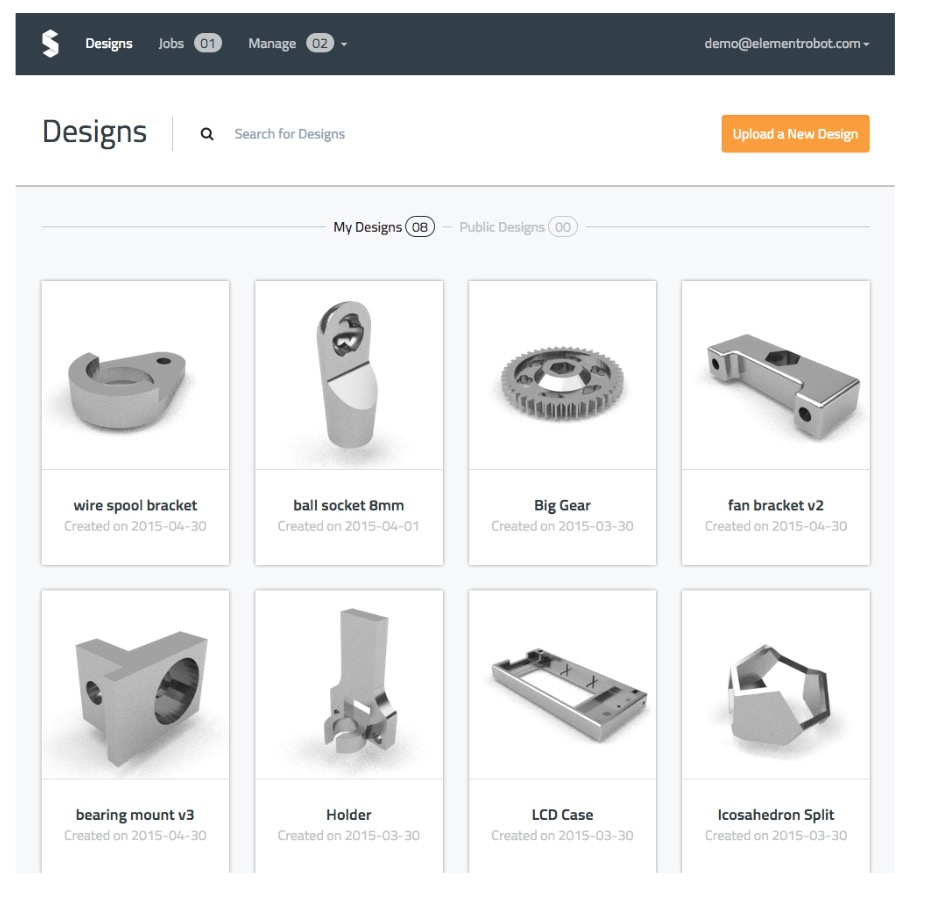

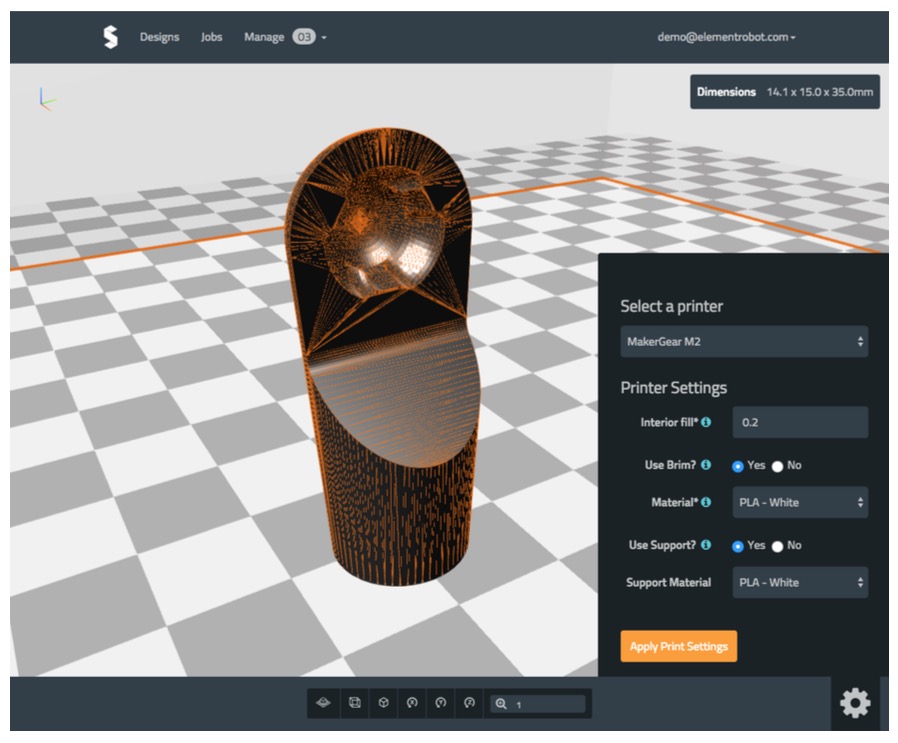

- Distribute Access: Enable multiple users to prepare and order 3D prints effectively. Set pricing and print approval process for employees requesting quotes using our simple embedded widget.

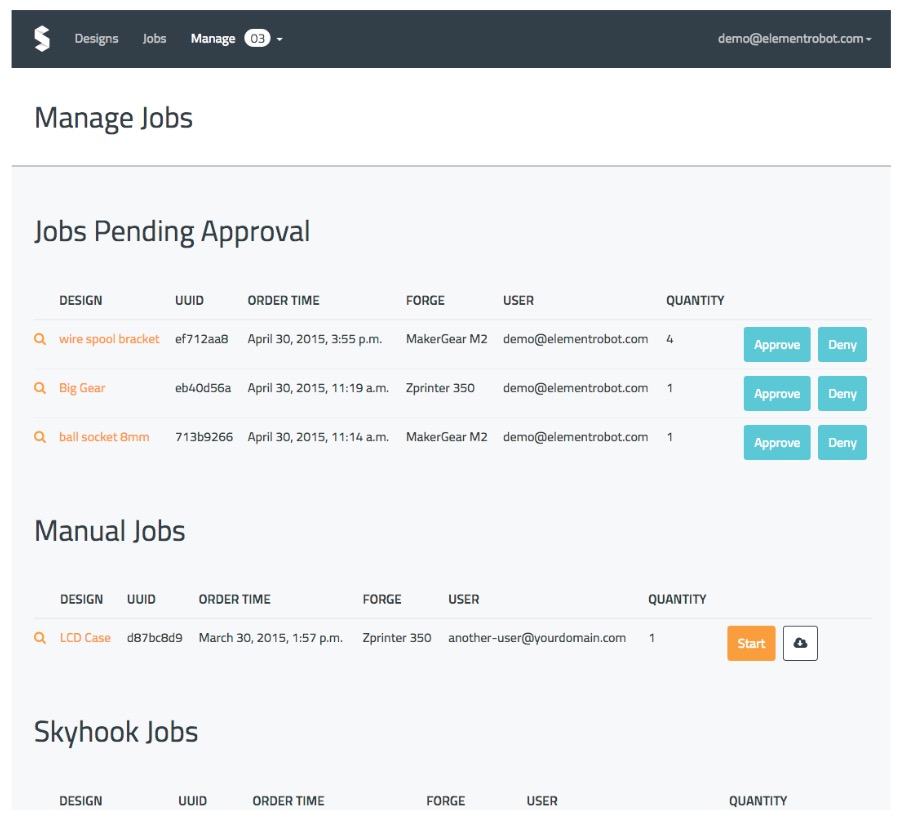

- Operate Effectively: Reduce labor by automating print queues, manufacturing instruction preparation, and machine communication.

- Unify Workflows: Use Skyforge as a central platform to connect design files, quotes, manufacturing parameters, and print queues. Keep your additive manufacturing systems simple.

The problem they’re trying to solve is that there simply isn’t any proper industrial level solution to manage a fleet of 3D printers that are used by groups of people.

We understand this problem, having spoken to makerspaces and other institutions in this scenario. It turns out each has had to invent homemade solutions to provide quotes, invoices, availability, job queuing and many more administrative tasks associated with managing a fleet of 3D printers. It’s not a fun job and the homemade solutions are often crappy.

Skyforge provides a way perform all this management – in the cloud. An institution could configure their equipment in Skyforge and provide an easy-to-use web interface for their clients and users to request, track and manage 3D print work.

In the case of industry, there are even more administrative tasks to complete. Consider the case of a company manufacturing parts for an airliner: the entire history of the part must be recorded for later analysis. When the part breaks six months later, what were the 3D print settings that produced it? You Have To Know These Things!

Skyforge provides a way to track all of this and much more.

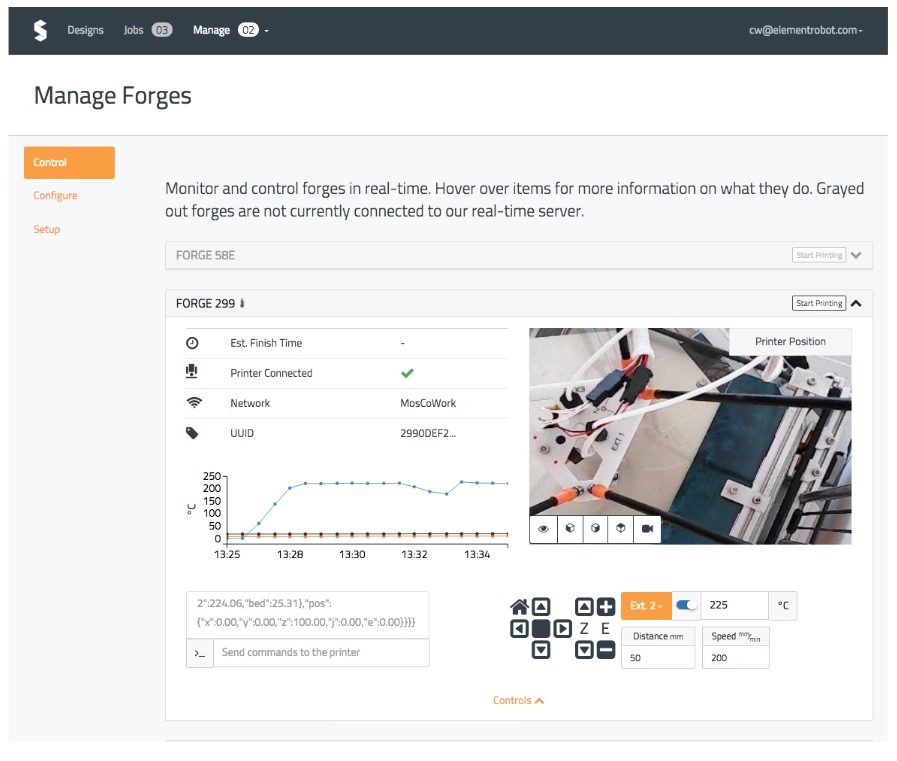

In some cases, Skyforge can even connect directly to certain 3D printers and drive them directly, using their “Skyhook” set top device. In other cases, the institution must manually run the 3D printers, but using the job instructions coming from Skyforge. This alone is a massive improvement in workflow for many organizations.

[UPDATE] Walker clarifies their work on interfacing with equipment:

We can set relevant print options for any 3D printer, including industrial machines, but we’re still working on gathering realtime telemetry from various industrial 3D printers: that takes collaboration with the manufacturer. Our normal practice is to do integrations for printer models once we have a client with that machine requesting integration.

Is there any competition in this area for Skyforge? We though perhaps MakerBot’s Innovation Center, which powers arrays of Replicators, but it only works for MakerBot equipment. Meanwhile, Skyforge works for almost any 3D printer, especially those of industrial quality.

From a company that began in 2014 with only three people, it seems that Skyforge is ready to grow. This is a very common problem that almost every operation using more than one 3D printer will have.

At this point Skyforge has prepared their service for use by libraries, manufacturers and universities. And they’re now actively looking for clients that wish to optimize their 3D print operations.

If you have several 3D printers in your shop, you’d better have a long look at Skyforge.

Via Skyforge