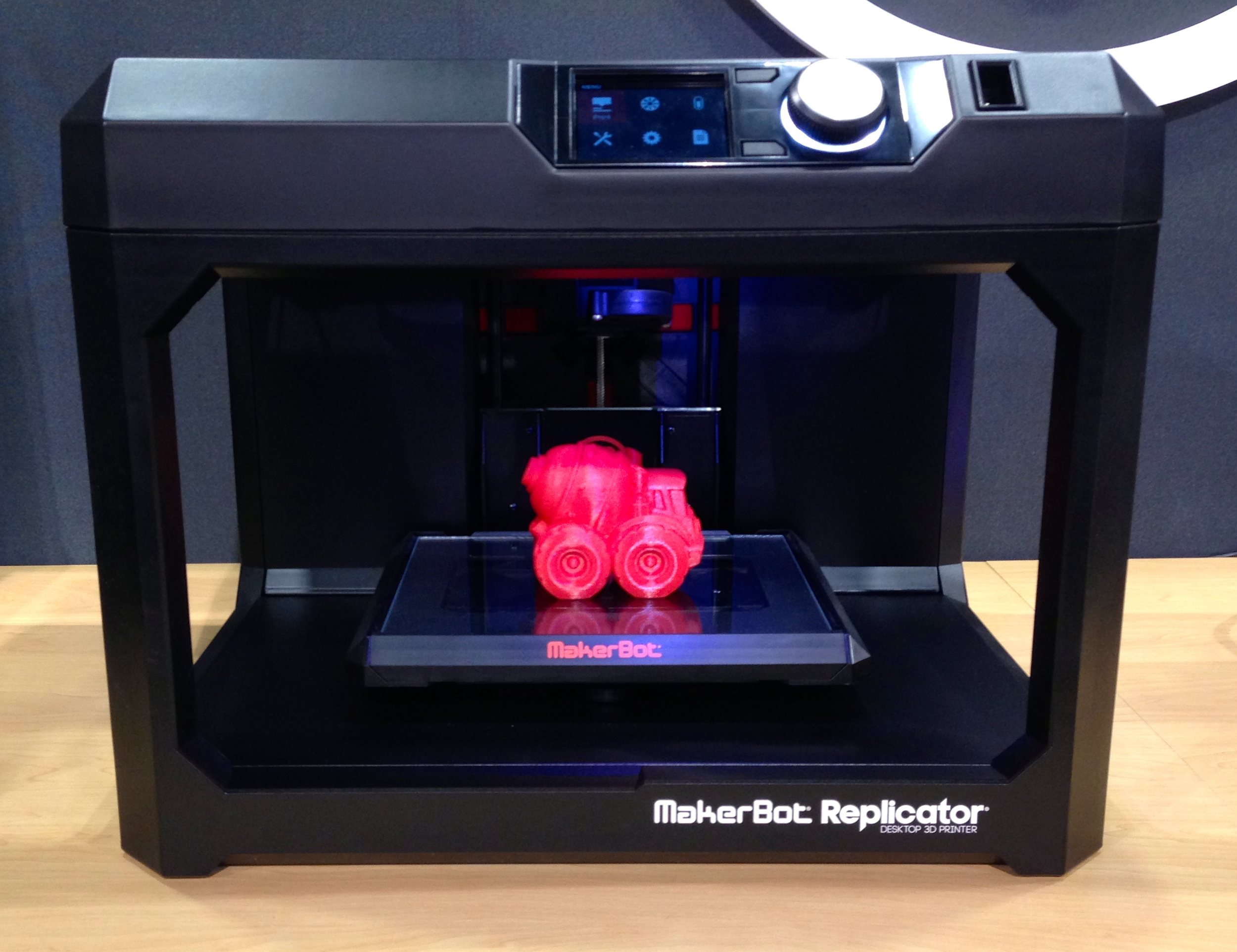

For the majority of the thousands of IT office product dealers and resellers in the US, 3D printing is a new technology.

Much like the laser printers from thirty years ago, or the digital cameras from twenty years ago, 3D printers represent a new technical device they may want to add to their inventory and sell to their customers. For those resellers in the business of selling computers, copiers and 2D printers, they will have to invest in some basic training to get their employees up to speed on 3D printing quickly so they will be comfortable marketing and selling this new technology. They also need to think about what their potential revenue will be from this new product in terms of upfront sales and recurring revenue.

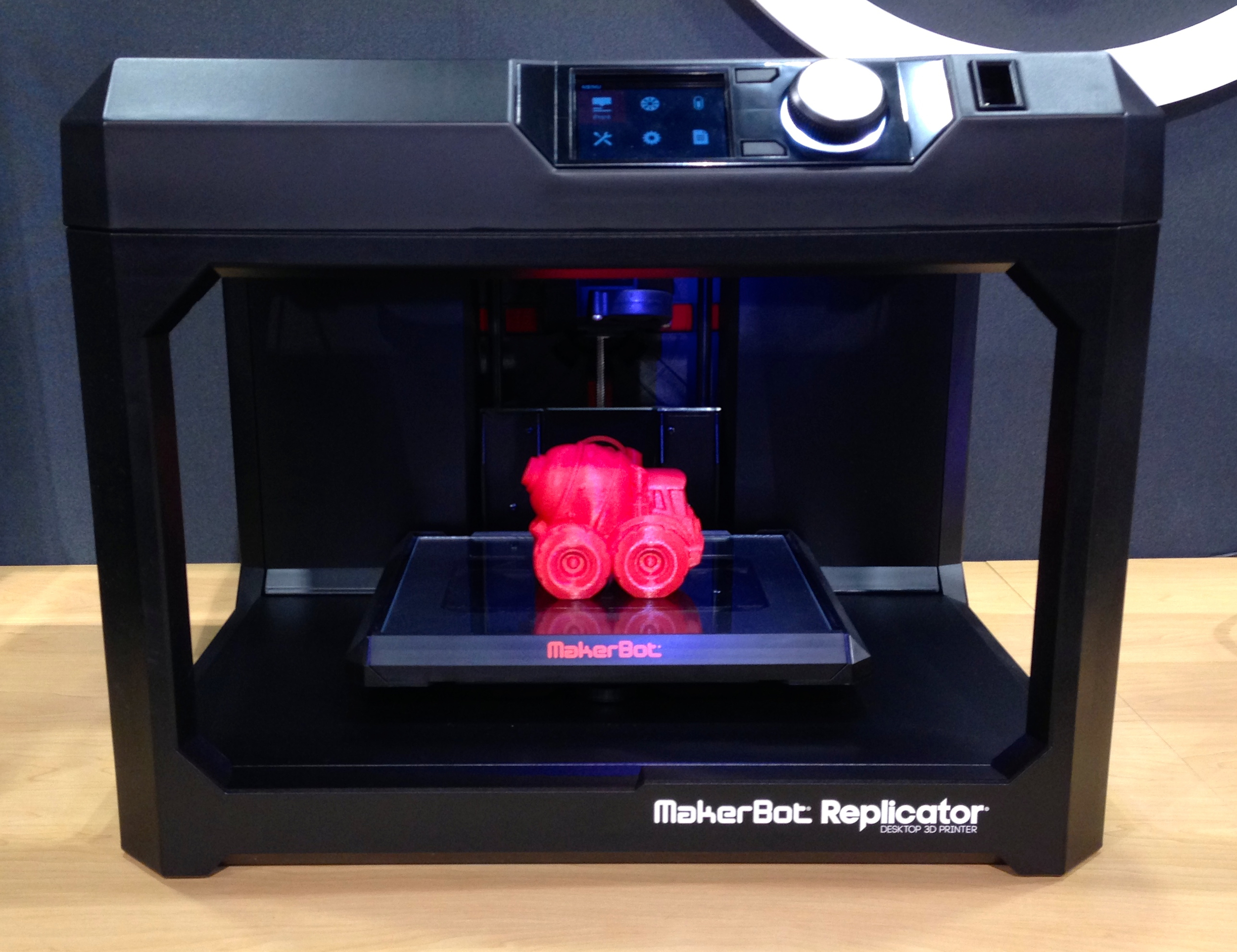

In the 2D printer and copier world, the initial hardware sale is only a portion of the total revenue a reseller counts on. In many cases, the ongoing revenue stream from the printer/copier consumables for these devices adds more profit to the resellers’ bottom line than the upfront sell price.

An example of the upfront cost of a printer in relation to the consumable costs over the projected lifetime of the printer is shown in the graph below.

It is clear to see that the initial cost of a typical desktop laser printer pales in comparison to the ongoing costs spent over the lifecycle of the printer. The upfront costs include the purchase price and any installation or configuration costs. The ongoing costs include all the consumables: the toner, maintenance kits, and related parts. A $500 printer might cost ten times that much over its lifetime, depending upon how long it remained in use. Resellers have known this for years and they have counted on this for much of their supplies revenue. This is why some 2D printer manufacturers gave away printers for very low prices, or for free in some cases, as long as a customer purchased a full set of extra toner cartridges at the time of purchase.

For example, the HP Laserjet 4/4M was introduced over twenty years ago. The toner for this printer, the 92298A cartridge, is still being sold today. For people that purchased this printer back in 1994, they have spent, on average, thousands of dollars more on the toner than the original purchase price. For a reseller that sold this printer, that means a much larger revenue stream from the consumables vs. the upfront sale.

Will today’s resellers be able to count on this same revenue stream in the 3D printing world? No one knows for sure and this is where the comparison to 2D printing ends. A 2D printer might print hundreds of pages a day, and use a couple of toner cartridges a month. For the consumer 3D user, the number of “prints” is going to be much smaller. If we assume a $1,000 upfront cost for a FDM type 3D printer, and the user goes through one roll of standard PLA filament per month at $30/each, over a five year period, that user will have spent about $1,800 on filaments. Although this is more than the original cost of the printer, it is not even close to the revenue stream a 2D printer brings in.

So if a reseller is not going to see a big ongoing revenue stream, will the reseller be willing to invest in this new product set? I think they should, and for a number of reasons.

Growth: Most research firms project the 3D industry to grow at a substantial rate over the next 3-5 years. In fact, Gartner predicts worldwide shipments of 3D printers to reach over 217,000 this year – almost double the rate from last year. They note that 3D printer shipments are “poised to increase dramatically” in 2015. Although a big chunk of these will be sold online, there is still a huge opportunity for the reseller community to take advantage of this growth in shipments. Resellers should start to forge relationships with manufacturers and/or distributors to gain access to their products on a direct basis to get the best price.

New Materials: Almost every day we read about new materials being announced by the many companies that are developing filaments. Some of these filaments come with a higher price tag than $30. There are filaments already on the market at double this cost. Selling these products will help the reseller increase his revenue. These new materials will undoubtedly lead to innovations in prototyping and fabrication, and will increase the number of 3D “prints” overall. Again, another potential increase in filament sales and revenue for the reseller. In addition, the technology is improving at a much faster rate than a few years ago and users may upgrade and/or trade-in their 3D printers sooner than expected. This technology refresh will lead to increased printer hardware sales for resellers, and to the potential for used equipment sales – a market that does not quite exist today in the consumer 3D world.

Services: Although most consumer focused 3D printers are easy to use and set-up, there will always be a group of customers that want local support. In the 2D printing world, some customers call a technician to install new toner cartridges – a simple task that most customers can do themselves. In the 3D world, resellers have an opportunity to sell services such as installation, setup, parts replacement, cleaning, and possibly installing and/or upgrading CAD software. A typical service call can bill out anywhere from $150 to $300 or more depending upon the complexity of the service required. These calls are a big profit area for resellers that provide service. If a reseller has an installed base of customers with 3D printers, they could see an increase in service calls and, consequently, an increase in service revenue.

Convenience: As the home user market expands, users will want to pick up their 3D supplies at their local office products reseller much like they do today for their pens, paper and other office supplies. Once the consumer is in the store, the reseller can up-sell/cross-sell these consumers with items that might not even be related to 3D printing. Just like the much sought after shelf space in the local grocery store, getting products in front of customers in person will lead to increased sales and profits.

Wow Factor: Like the iPod, the Xbox and the Wii, 3D Printing is the new “cool” technology that many consumers are hearing about, and talking about. Gartner predicts that “end-user spending on 3D printers is expected to increase from $1.6 billion in 2015 to around $13.4 billion in 2018.” This is a huge increase in spending in just a few short years. Any reseller that does not add this product line to their bag of tricks may be missing out.

We are still in the early stages of the 3D product life-cycle and there are probably many more reasons for resellers and dealers to invest in 3D printing. I see a very bright future for 3D printing and those resellers that do invest can ride the wave of the expected explosive growth for the next few years. Any reseller that does not jump on this opportunity will be left selling typewriters and fax machines to a dwindling market.

Chris Carroll is the owner of TDF Industries LLC, a 3D printing consulting company that provides industry research and reseller training. Chris has twenty years of experience in the printing industry with Hewlett-Packard and holds a BS and MBA from Rutgers University.