3D software MachineWorks announced an amazing new feature in their upcoming Polygonica release: the ability to automatically recognize 3D CAD features from a 3D mesh.

Here’s how it works, for those unfamiliar with CAD and Meshes. A mesh is a digital description of a 3D shape in the form of a network of polygons (typically triangles or “quads”). Think of it like a fisherman’s net that’s bolted to the exterior skin of an object.

A CAD model is also a digital representation of an object, but it is made not from polygons covering the skin, but instead a series of intersecting primitive objects, such as cylinders, flat surfaces, cones, curves, etc.

The other very major difference is that CAD tools permit you to individually (and numerically) change the dimensions of these primitive objects. Example: change the diameter of a hole by entering a different number. This type of change CANNOT be easily done if the object is a mesh, as you’d have to individually and precisely move dozens, hundreds or even thousands of polygons.

The problem is that often you’ll have only the mesh and not the CAD version of a 3D model, making it incredibly difficult to make modifications.

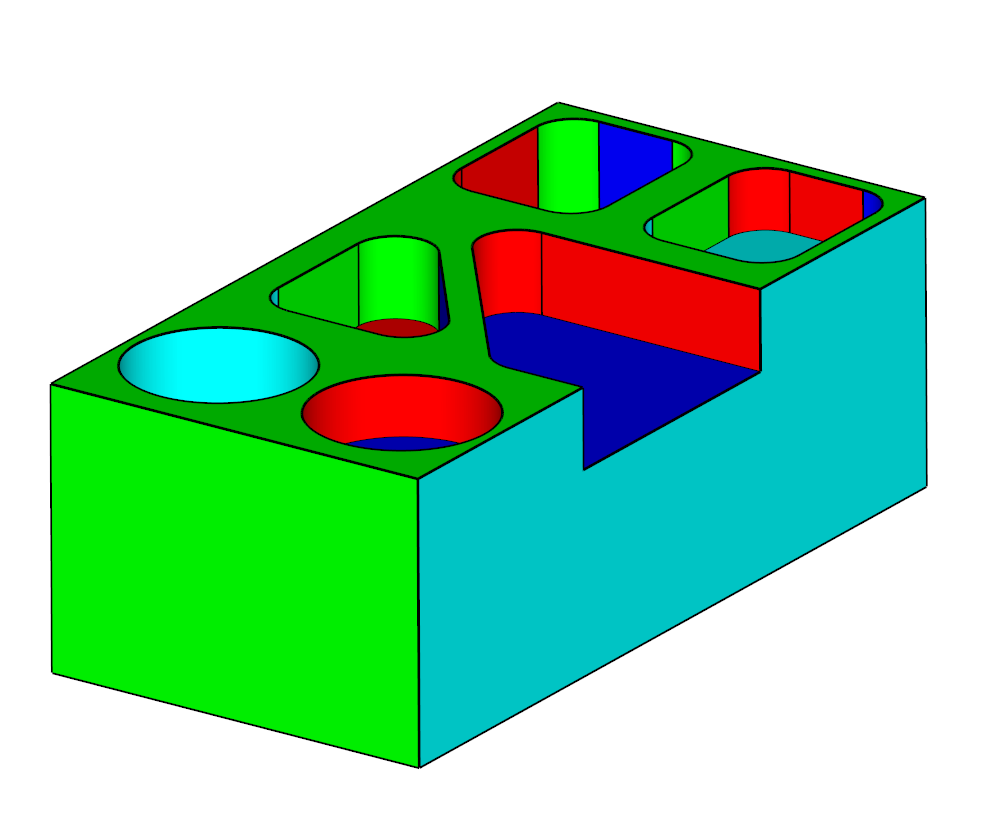

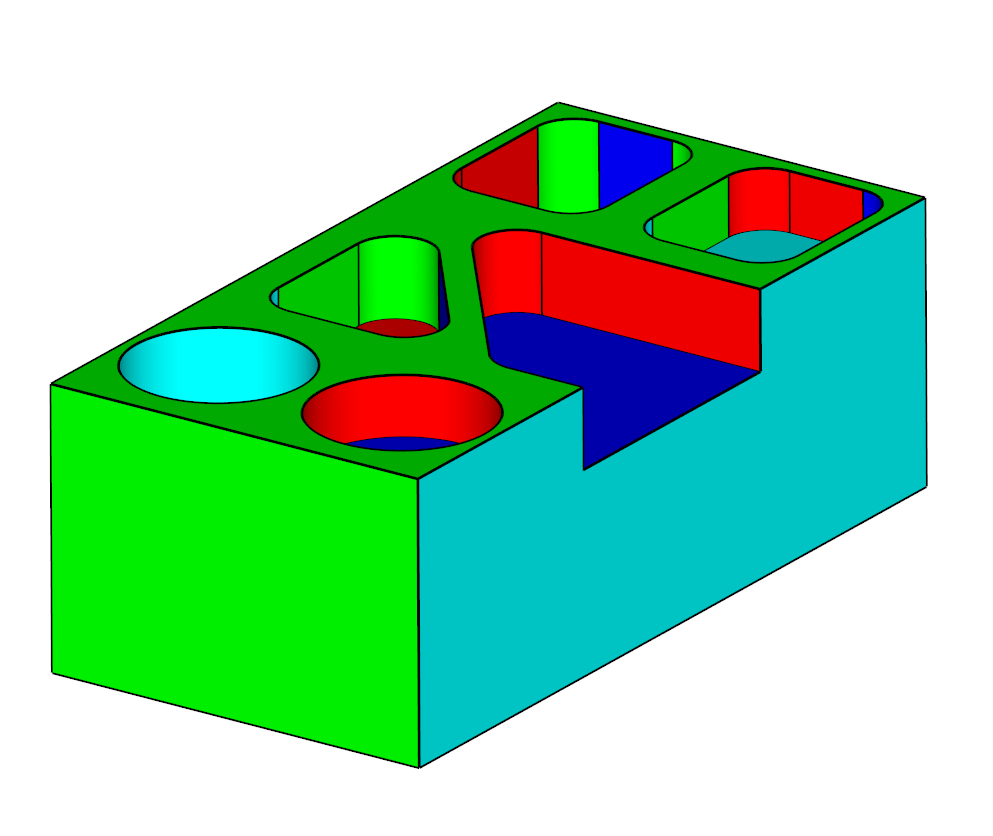

That could change with the new Polygonica software, which automatically analyzes a mesh to identify CAD-style components. At top we see a simple object with highlighting indicating the detecting of several primitive CAD objects.

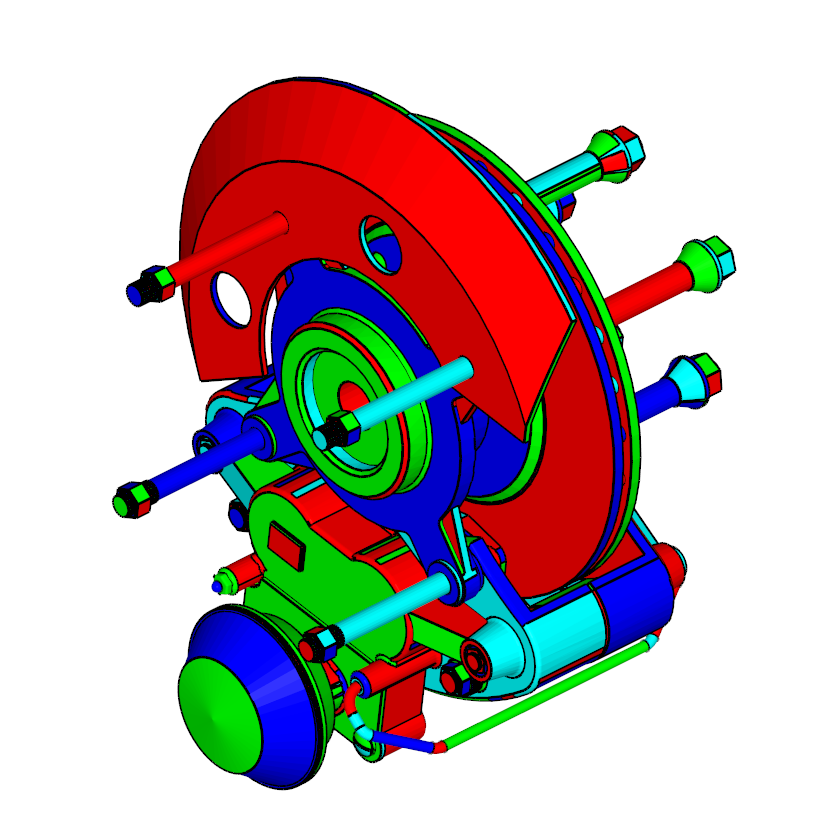

Here we see a much more complex 3D model that has been decomposed into the following components:

- Solid has 271582 triangles.

- Found 6368 features in 80.63 seconds.

- 3469 planes

- 153 spheres

- 1612 cylinders

- 931 cones

- 203 tori

While this feature may not be sufficient to handle the usually incomplete and messy 3D meshes obtained by 3D scanners, it likely can be quite useful on “complete” 3D meshes.

Via Polygonica