Popular 3D model utility software netfabb has released version six, which includes several incredibly useful new features for manufacturing.

netfabb provides a variety of utility functions to assist those performing 3D print workflow in manufacturing and prototyping environments. The idea is to increase the probability of 3D printing success by making improvements and repairs to a 3D model before it hits the printer.

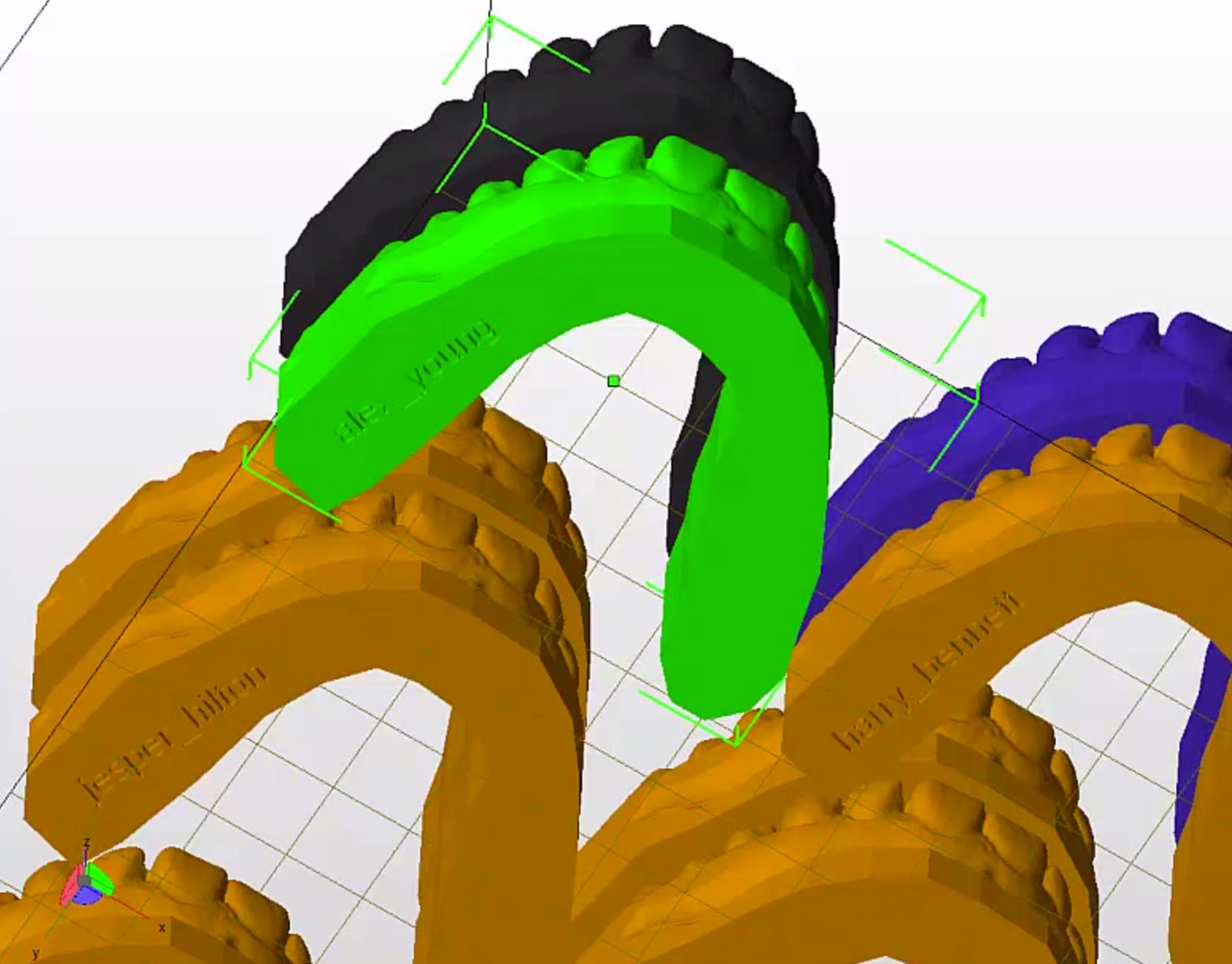

They’ve provided a terribly easy way to apply labels to a collection of parts. Here we see the results of applying patient’s names to a set of jaw prints.

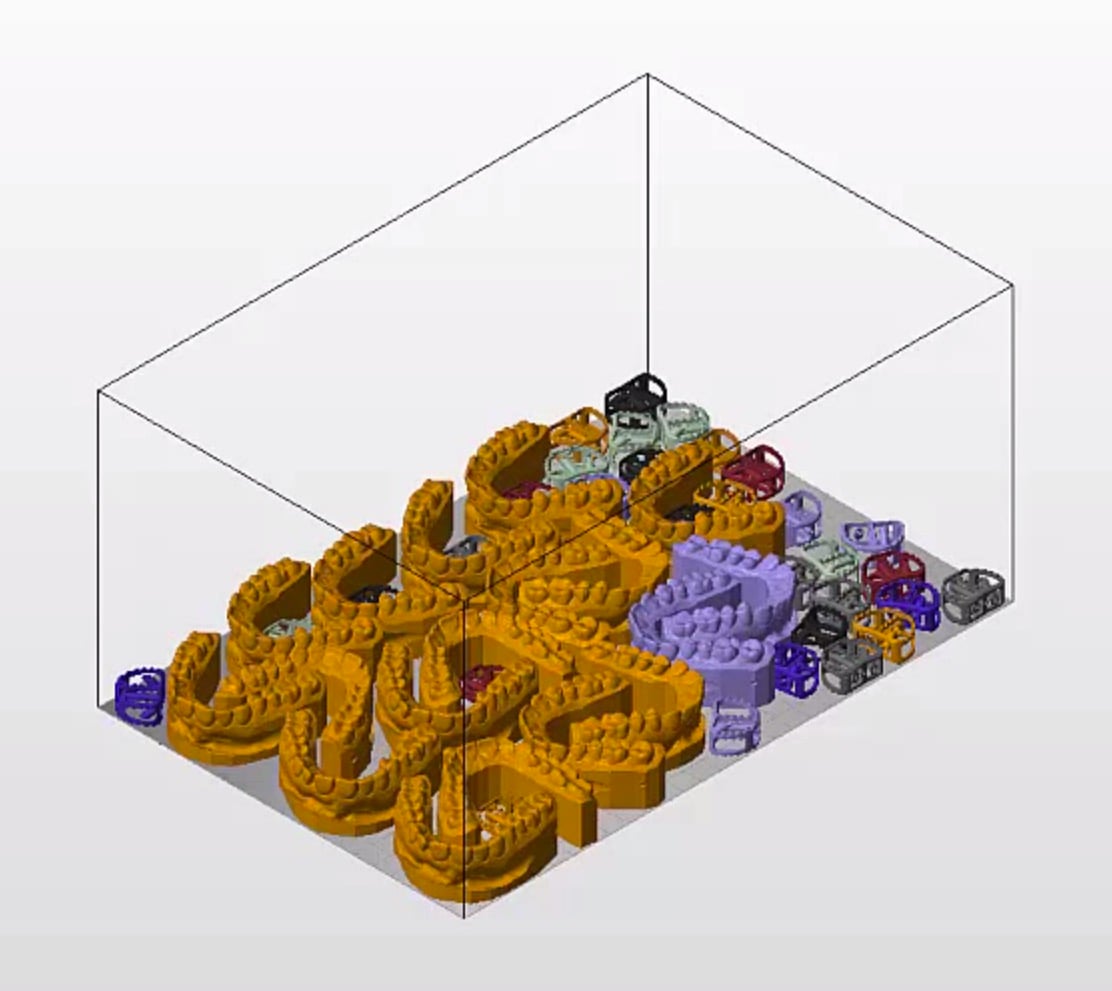

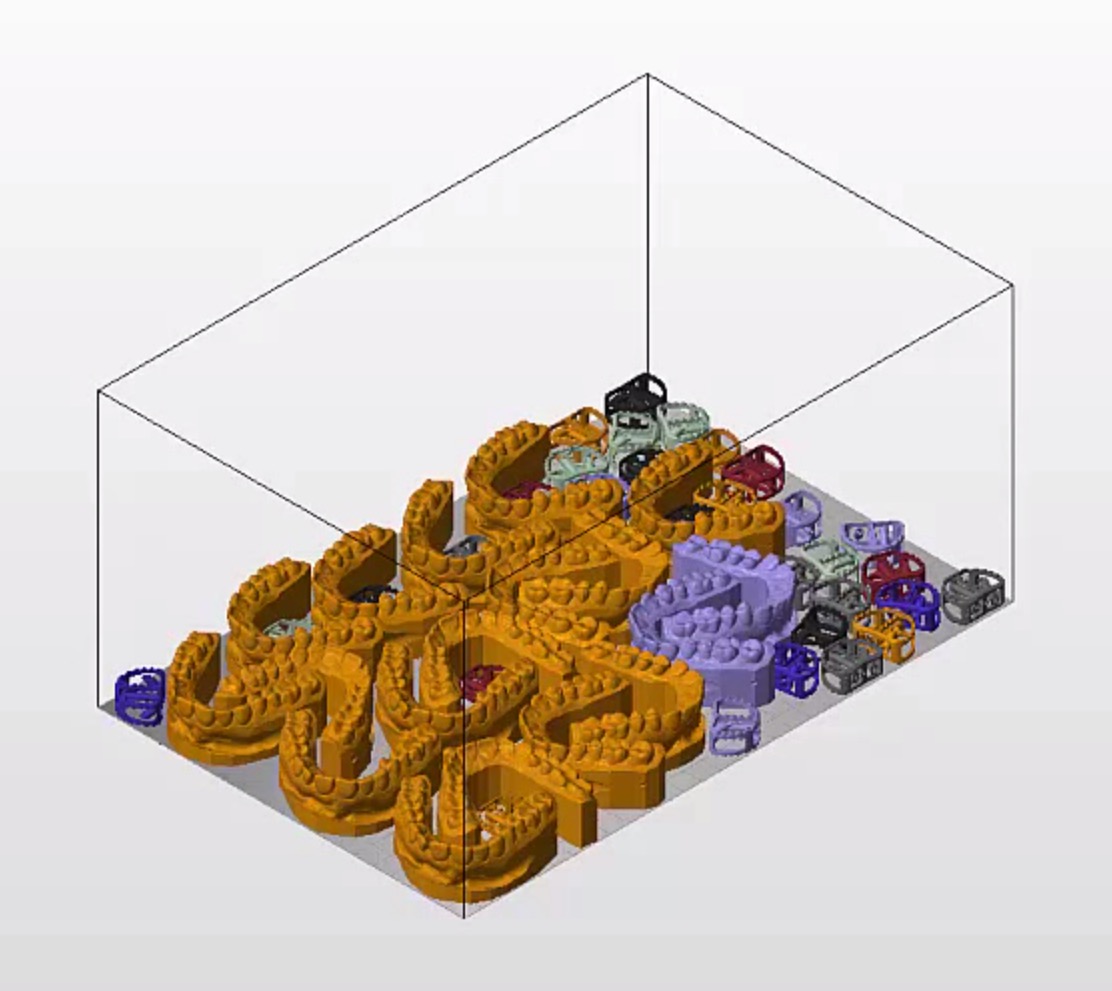

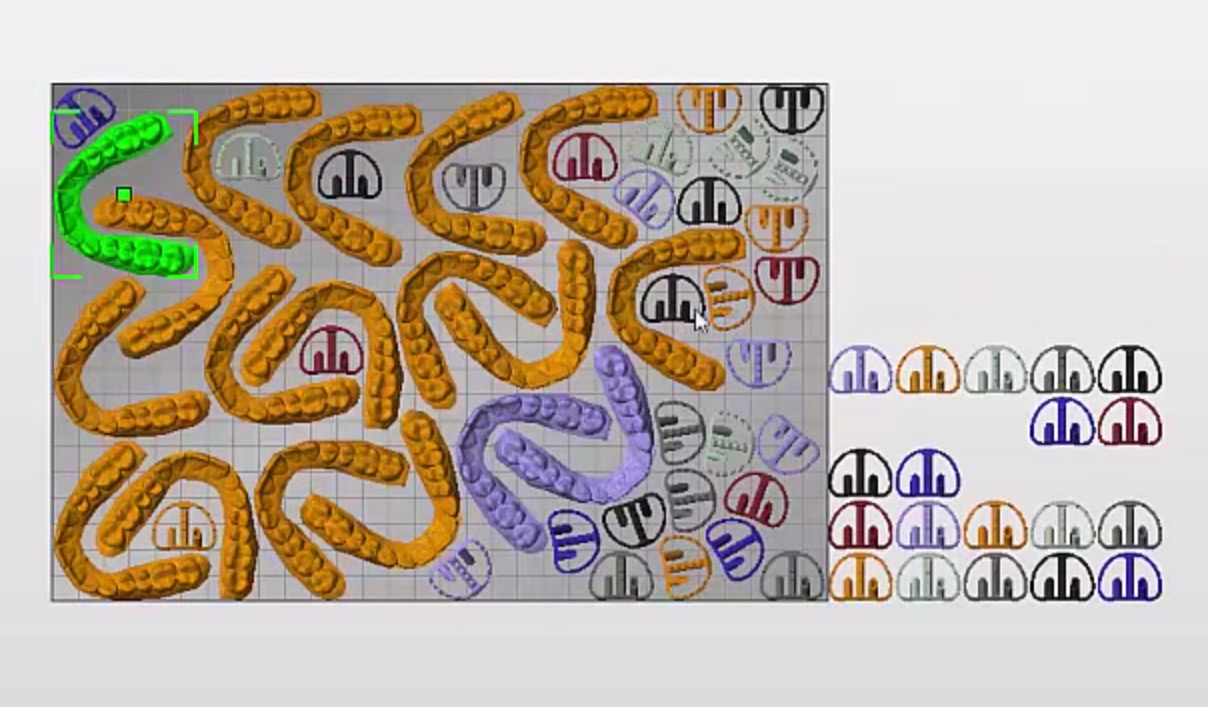

They’ve also provided a much more flexible way of arranging a plane of parts on a print surface. You can specify, for example, the minimum distance between parts and even rotate them in a pattern. Here we see how we can tetris in parts where you cannot in other tools because the objects’ boundary box would be violated. The resulting print configuration is described in detail in a print report that can be used for tracking customer print jobs.

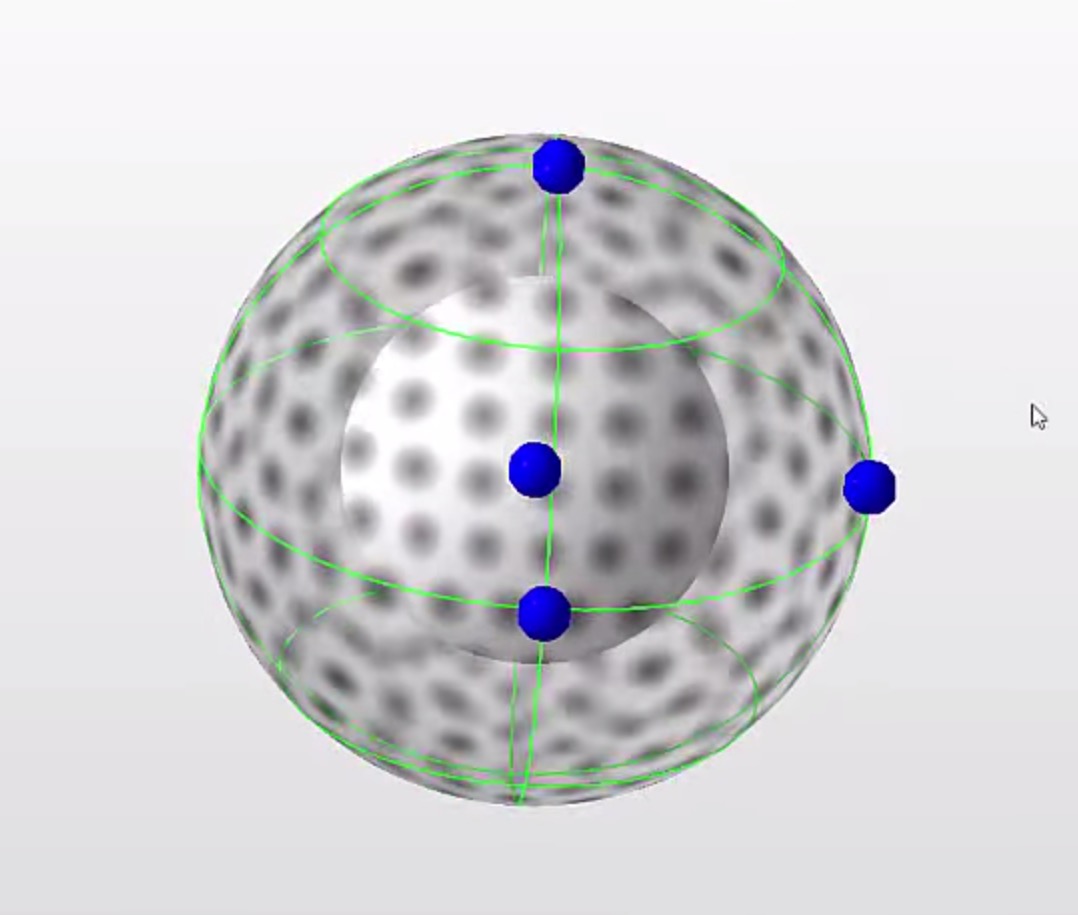

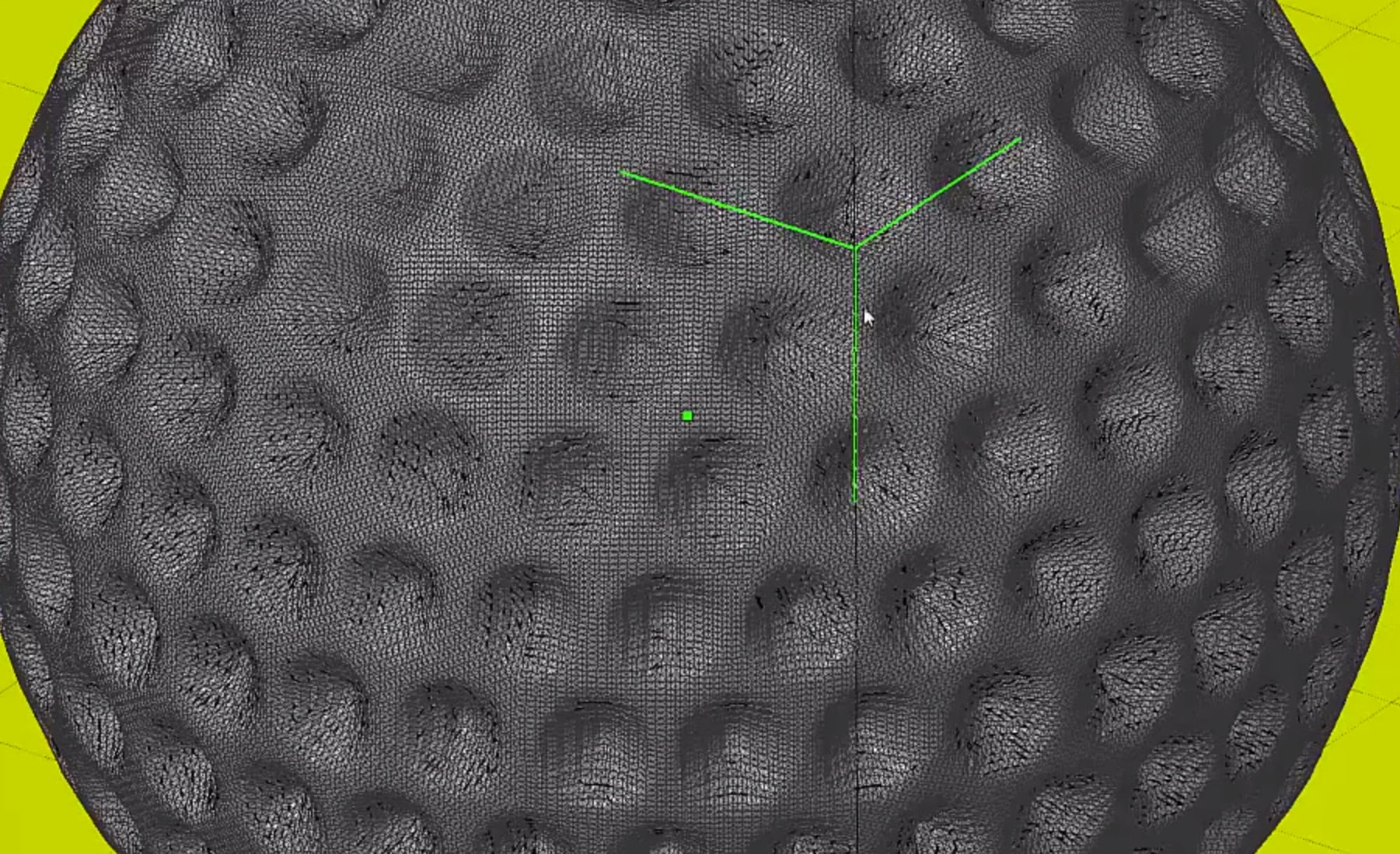

They’ve now introduced a way to apply textures to 3D models. You are able to use both an “assisted” or “manual” methods of applying a texture to a surface. The assisted version looks very powerful.

But even better, you can use the applied texture to alter the 3D model! Here we see a golf ball texture created almost instantly by requesting netfabb v6.0 to extrude the black spots on the texture inward slightly. This feature can permit all sorts of interesting possibilities to modify object surfaces, and I’m sure we’ll see some innovative practices develop with it.

The new version of netfabb also now supports the new 3MF file format, recently launched by the 3MF Consortium. This is not surprising, as netfabb is a member of the 3MF consortium.

There are other improvements, too. For full details, check them out at the link below.

Via netfabb