A new startup hopes to capitalize on the custom-footwear market by 3D printing shoes that precisely fit the wearer.

Footprint Footwear has apparently implemented one of the classic hypothetical businesses for 3D printing: custom fit footwear. They explain the process:

Footprint is a unique process that generates point-specific support structures through algorithmic pattern generation. Through case-specific advisements from certified podiatrists and pedorthists we analyze individual foot structure and gait pattern to create unique footwear solutions that are built exactly to your specifications.

There are huge advantages to this approach, primarily because everyone has different feet. In fact, your left is likely not the same as your right! The Footprint Footwear system will account for all these measurable difference and produce a unique shoe for you.

Orthotics, the science of making shoes fit properly, is a very well-known process. Here we see a company taking those principles and implementing them in software, combined with a 3D printing process to produce correct footwear.

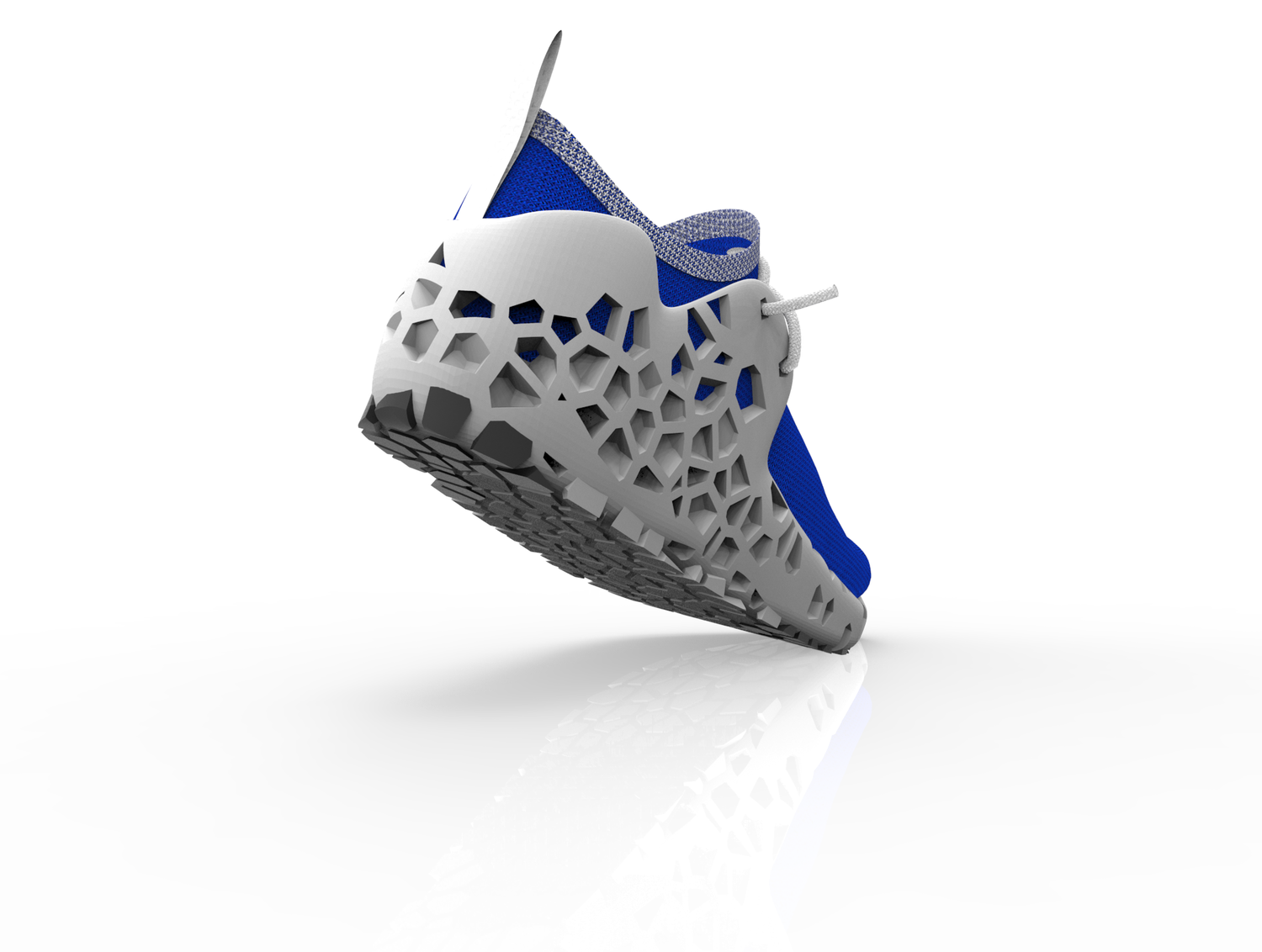

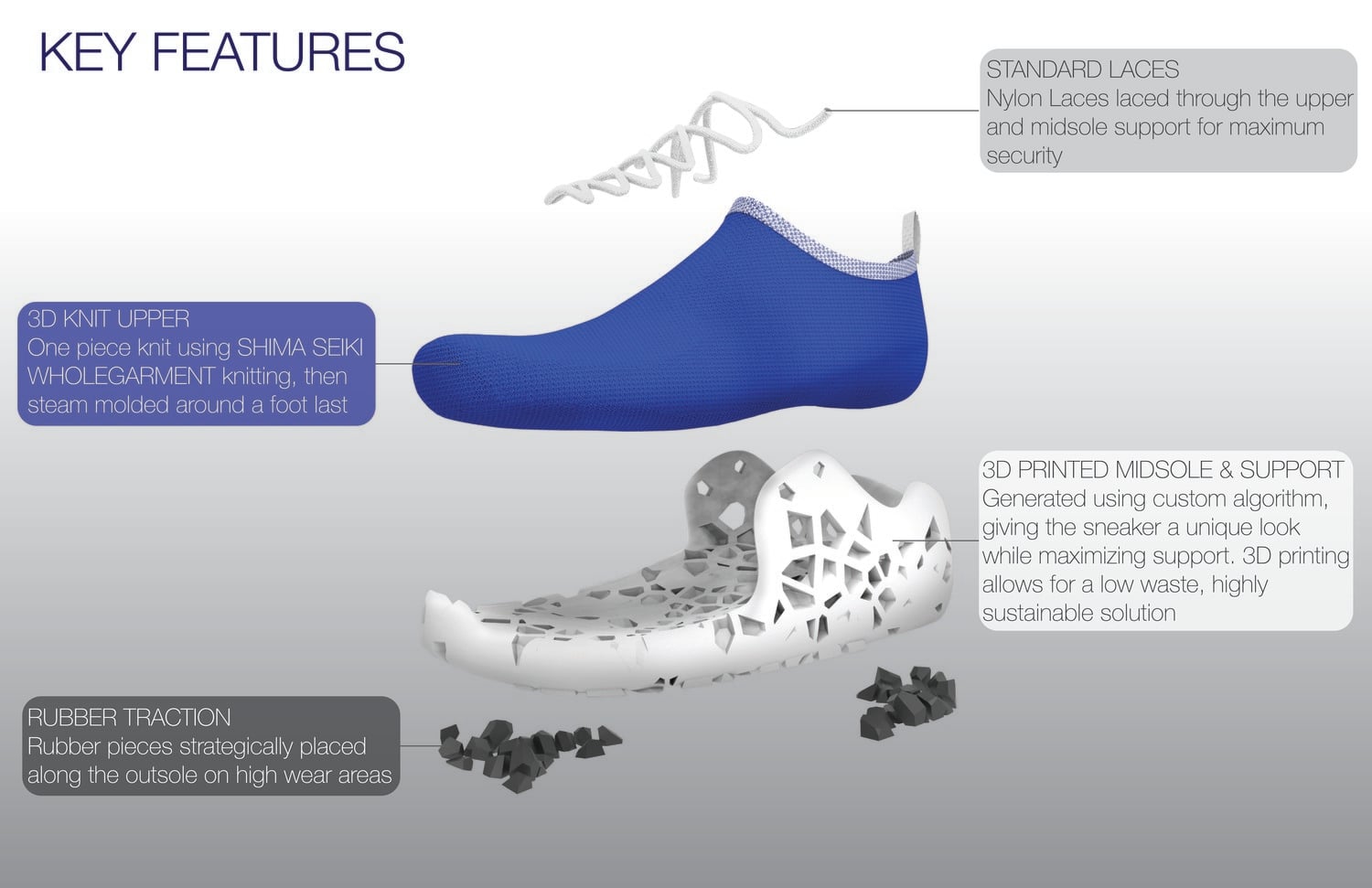

The output in this case is a shoe made from 3D printed and non-3D printed components. A knit upper is conventionally made, while the midsole and support are custom 3D printed.

While this is conceptually a wonderful idea, we have two key questions.

First, the production of these midsoles is said to use three different approaches: Ninjaflex plastic extrusion on inexpensive desktop 3D printers for prototyping, which makes sense; Stratasys Connex TangoPlus flexible digital material for testing; and finally, “production intent” using SLS nylon 3D printing on a 3D Systems unit. We’re pretty certain production units could not be made with NinjaFlex or TangoPlus, as those materials would quickly wear out. But it seems they have not yet made a nylon version?

Secondly, how, exactly, does one obtain the personal data to create the customized 3D model? Is this done using a 3D scanner? Some type of specialized “step on and measure” device? Where is it? Do clients have to travel to a special lab to be measured? Where might this lab be? Is there one in my area? Can I do the measurements at home using an app or paper cutout mechanism?

The answer to the second question is critical. If it can only be done using specialized equipment at central locations, then it will be much harder for Footprint Footwear to grow their business, as they have to set up physical locations in many cities, provide staff for them, etc.

But if they can figure out a way around that issue, they may have a big business here.