We managed to score an onsite tour of Full Spectrum Laser, the makers of the Pegasus and Phoenix Touch high-resolution 3D printers.

Full Spectrum Laser did not begin as a 3D printer manufacturer; in fact, they began as a maker of high quality laser engraving units, which they still sell in great volumes. Multiple examples of their laser products are on display in the showroom, including their best selling product, the 40/45W Hobby Laser.

As interesting as they were, we weren’t there for laser engravers; instead we wanted to get a closer look at the two resin-based personal 3D printers the company has recently developed: the Pegasus Touch, developed last year, and the new upcoming Phoenix Touch.

FSL operates in a 20,000sf facility just east of the Las Vegas airport, where they employ around 37 folks, who create literally everything on their product shelf. The company designs all machines – and builds them onsite, too. They even design and manufacture their own 3D printer resins onsite. We also saw their support desk taking calls from clients within the busy office.

A large room is dedicated to manufacturing. Here we see a set of frames ready for component installation.

FSL has a small team of workers busily assembling units, like this fellow. We’re told they’ve now caught up on orders and the wait lists are pretty much gone.

There’s nothing more satisfying than seeing completed units ready for delivery. Here’s a few of them. We were told each unit is thoroughly tested, including actually printing a test object before shipment.

One very interesting, but lesser known feature of these machines is the associated software, RetinaCreate. Like most manufacturers, FSL ships custom software with their machines (which, by the way, is ALSO made in the building). The software performs all the usual functions of slicing, positioning, scaling, rotating, etc, but it also contains some very interesting additional features.

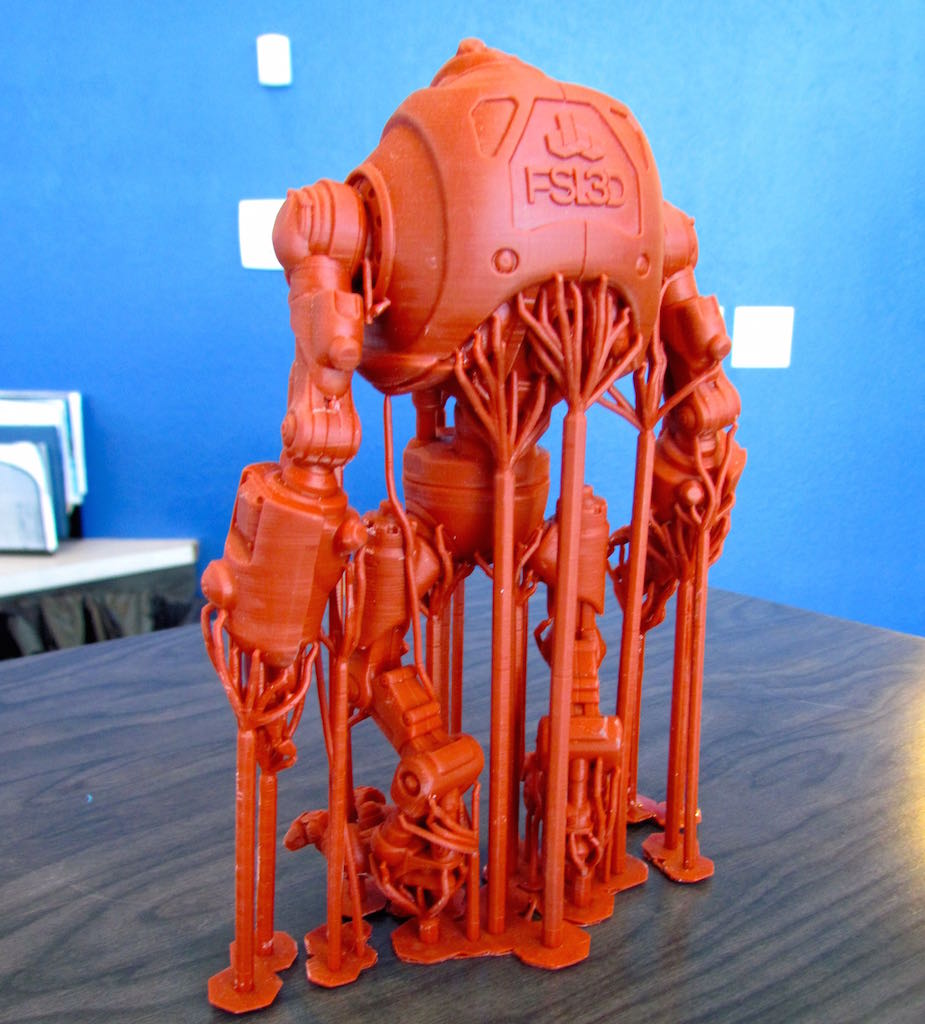

The feature that most impressed us was the generation of support material. FSL’s software is capable of generating the very usable tree-style supports that we’d previously seen in MeshMixer. These are far easier to remove than the intensely dense pillars often found in other software – and they use much less material, too. But here’s the really interesting thing: if you look closely at the bottom of this model, you’ll see that the supports are actually CURVED! You can even draw supports in manually if required.

RetinaCreate has even more features, like version control, touchscreen support and automated shelling (which makes a model hollow to dramatically reduce material use). Another very useful feature is “auto rotation” to precisely rotate the model for optimal print times. Print jobs, once set up can be saved for future printing.

We’ve written about the Pegasus and Phoenix machines’ capabilities before; these are very accurate resin-based 3D printers capable of printing amazing things. FSL has taken the interesting step of hiring a full time art director to oversee the production of demonstration models, like this incredible wolverine figurine. This item was printed in three parts and assembled – but the talons are actually made from metal and produced separately for addition to the model.

The company currently sells nine different resins, including various colors, clear and several specialty resins: low shrinkage, casting and flexible. We understand Yellow resin is on the way, as well as several other colors. They don’t offer the color you want? The answer is surprisingly simple: in this image you can see a bespoke modeled superman, made from a mix of red and black resins. Yes, you can mix the colored resins to produce alternative shades! With the addition of a few new colors, you should be able to mix up almost any shade desired.

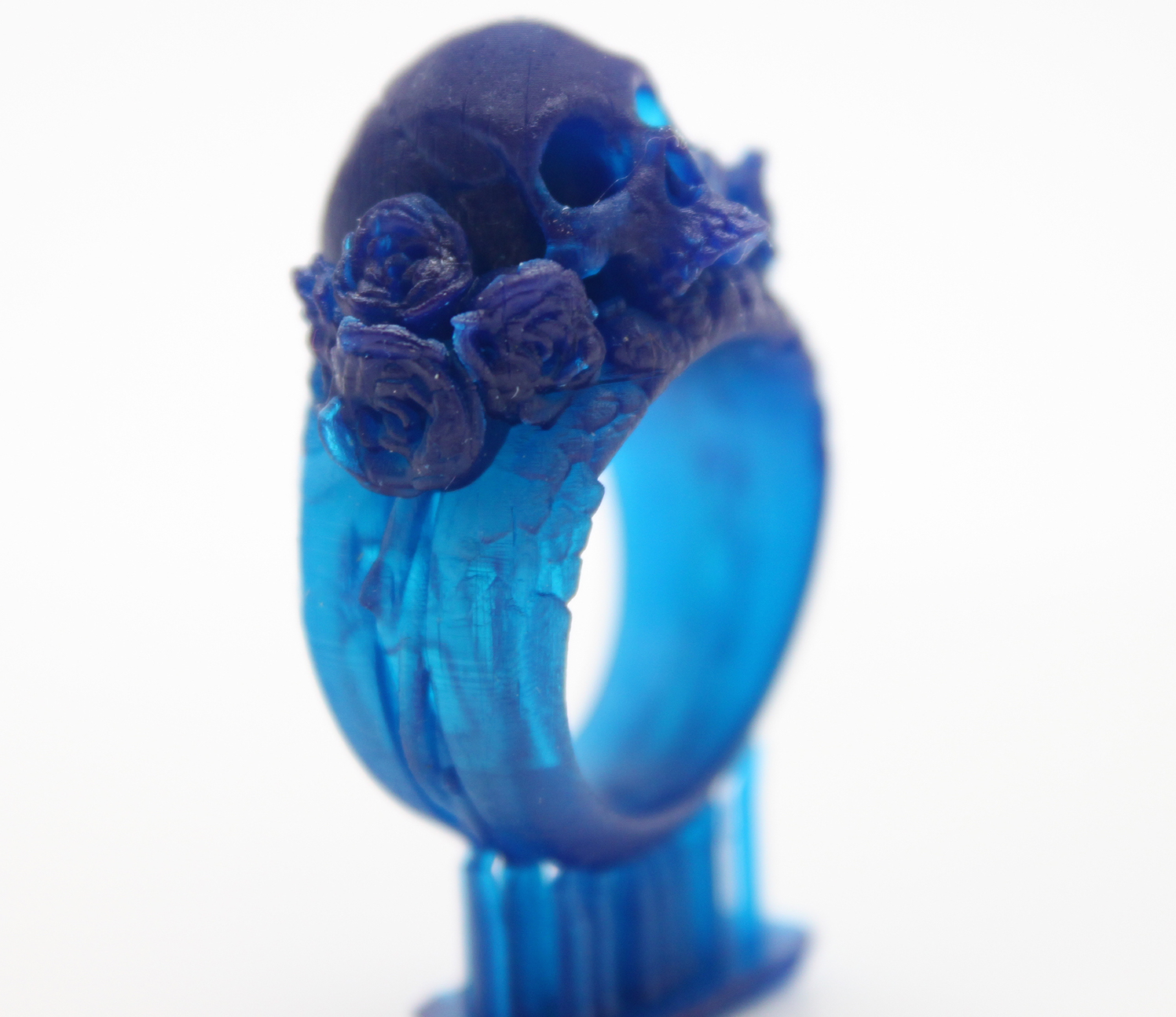

FSL’s latest machine, the Pegasus, looks quite good: it’s a DLP printer, not a laser as you might expect from a laser engraving company. Why go DLP? They found that DLP gives major advantages in terms of speed and ultra-fine details. Thus, they moved to DLP technology for the Phoenix line, and you can see the excellent results in this image.

This machine is not only accurate, but it’s quite fast, due to its “super vat”. It’s a specially designed resin tank that does not adhere to solidified resin. This means that the tank can be used indefinitely (other manufacturers consider tanks to be a consumable). It also means the printing can be a great deal faster because the machine does not have to slowly peel the print off the bottom of the tank for each layer.

We did get a peek into FSL’s development lab, where they continue to develop new 3D printing technologies. We’re not allowed to publish any details yet, but we can say this: Wow!

Meanwhile, we’re told the first Phoenixes will be shipped soon, likely “in the next couple of months”. The price of this unit (USD$3,499 for the basic model and USD$4,999 for the Pro) are vastly less than other commercial machines offering similar capabilities.

It looks like FSL could shake up the industry quite a bit with this new machine.

Via FSL3D