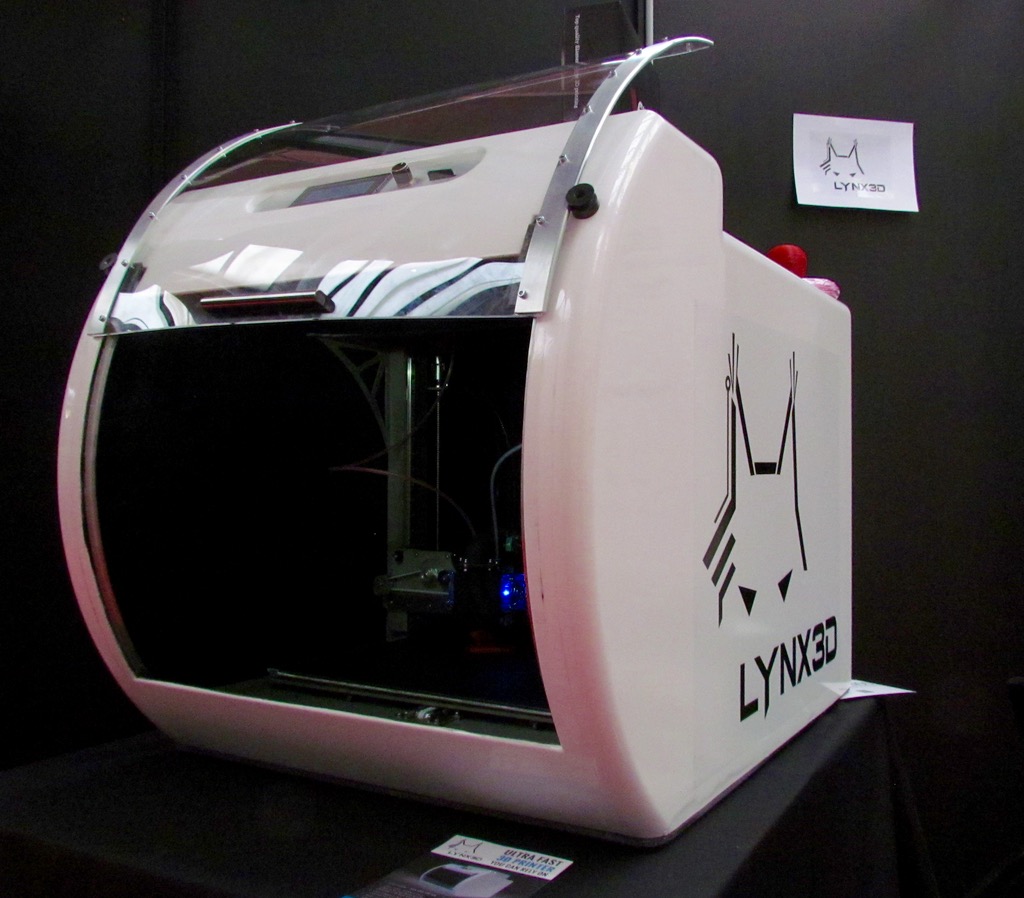

Lynx3D has released a 3D printer with some very unusual features.

If you’re launching a filament-based 3D printer these days, you’d better have some unusual characteristics, because the market is very crowded at this point. So what does Estonia-based Lynx3D have to offer?

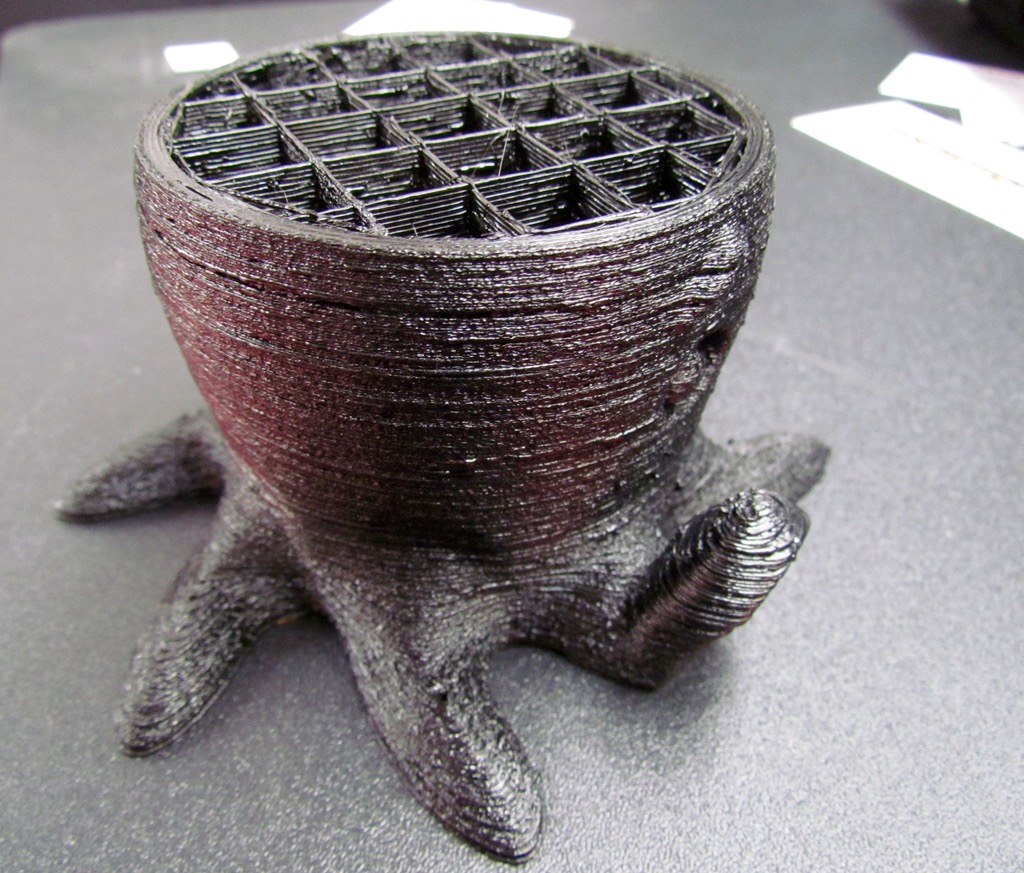

Their machine is targeted at engineers wishing to make strong prototype parts. It therefore does not have many consumer-oriented features and is used in different ways.

Specifically, the Lynx3D team wanted to develop a machine that is capable of printing strong parts in large sizes at great speed. Evidently they’ve been able to achieve that rare combination of factors.

The build volume is quite large on this machine: 400 x 300 x 400mm, several times larger than typical competing machines. But that’s not the most interesting feature.

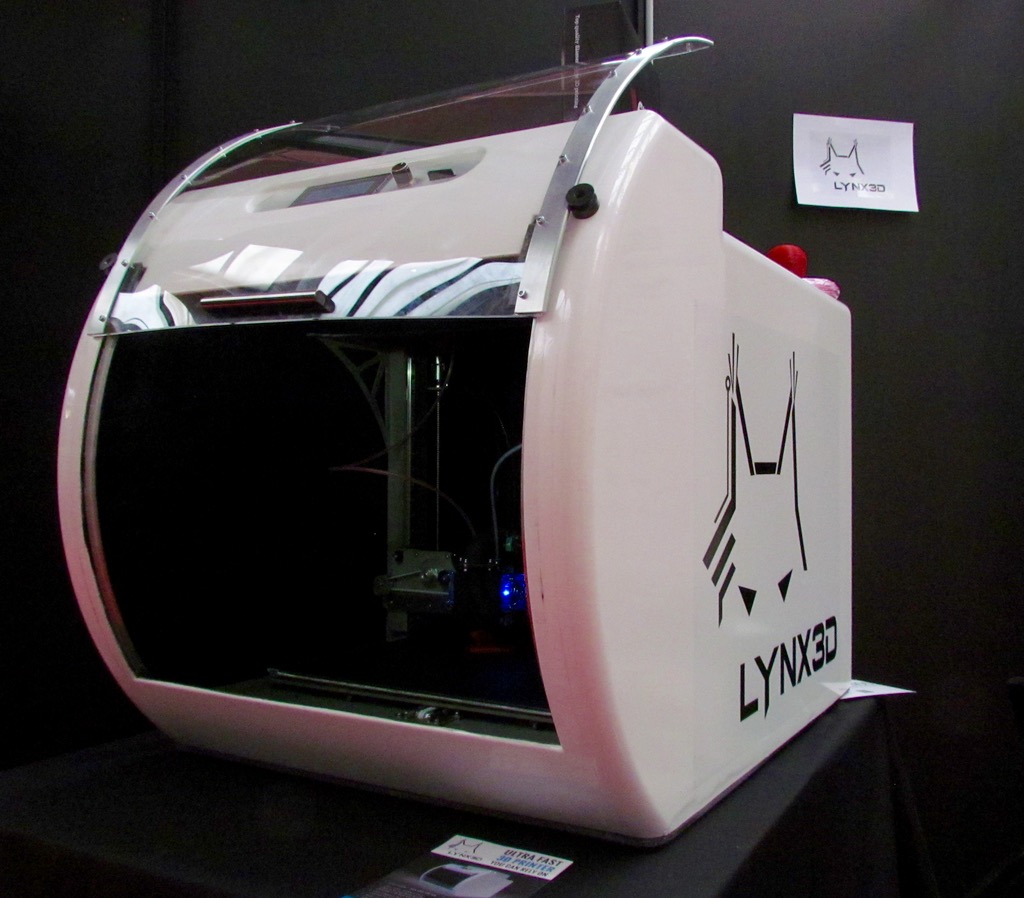

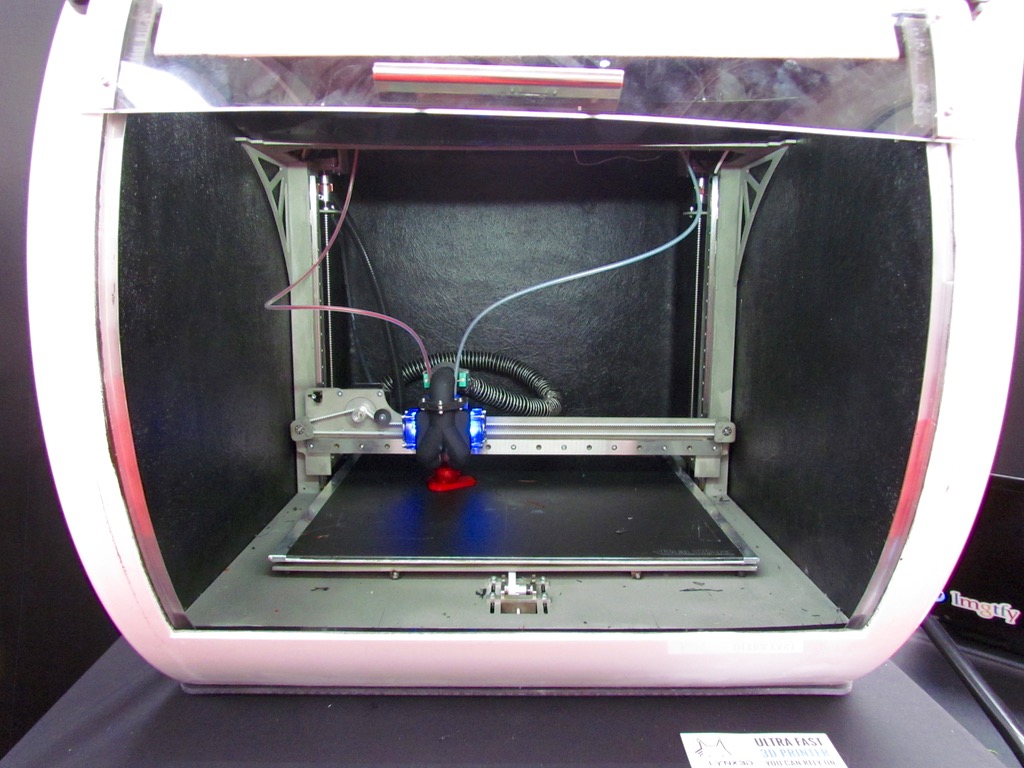

The print chamber is entirely enclosed and is heated by the print bed. Normally the environment inside the print chamber is only 15 degrees C below the print bed’s temperature, so it can be quite hot inside. In fact, this machine actually draws colder external air to the hot end to cool printed material more effectively than using in-chamber ambient air. Electronics are outside the heated chamber, protecting them from heat damage.

Speed is said to be very rapid, but there’s a catch as we’ll explain. The chassis is all metal, enabling rapid movement of the extruder, up to 600mm/second.

We were skeptical of this speed until it was explained that the resulting prints were of less precision than you’d normally expect – but that the prints were of sufficient quality for their target market. Engineers making parts do not always require fine details, so “rough” prints are entirely adequate. And that’s what the Lynx3D does: print large, rough parts at high speed. This print apparently took only 2 hours to print, for example, but note the level of print quality.

Due to the extreme speed, the company says the Lynx3D can only print ABS at this time, as it as the necessary flow characteristics for this type of high speed printing. In fact, they say that you must install the machine on a very rigid table, as table wobble will actually affect print quality.

To add to the speed, the machine can swap extruders in less than five minutes by releasing a single screw, as shown here. The speed comes from installing nozzles with higher diameter. 0.6mm and even 1.0mm nozzles are possible. Combining a fat nozzle with high speed should indeed result in very rapid prints.

The machine has been developed over the past 18 months by the CNC-experienced company, and is now available. Priced at €3,500 (USD$3,850), the machine is being produced in limited quantities at this time. We’re told they can produce a maximum of eight per month today, but are seeking manufacturing partners to drive it up to 60 per month. They’re also looking for retail partners who would like to sell this fascinating 3D printer.

Via Lynx3D