A report on PhysOrg describes how researchers developed an ingenious method of 3D printing with cellulose.

First, a reminder of what cellulose is: According to Wikipedia, it’s “an organic compound” that is “an important structural component of the primary cell wall of green plants, many forms of algae and the oomycetes”. In other words, it’s plant material.

But, you may say, cellulose has already been 3D printed in the form of wood filament. That’s technically true, but consider how that is accomplished: wood material is crushed into small particles and then mixed with standard PLA plastic to form a filament. When printing, the plastic melts and carries the wood particles into position within the 3D print.

The problem with pure cellulose is that it doesn’t melt if heated. That’s why wood filament manufacturers mix wood particles with PLA plastic. The plastic melts.

However, according to the report, researchers at Chalmers University of Technology in Gothenburg, Sweden have made an ingenious re-use of bioprinting technology to achieve true cellulose printing.

Bioprinting has the same problem as cellulose: you can’t “melt” living cells to print them. That would otherwise be known as “cooking”. Instead, bioprinters frequently use a syringe approach to squish out living cells without heat damage. They invariably use some type of hydrogel as a medium to hold the cells in place until they grow.

Here’s the interesting part: the researchers simply put cellulose into hydrogel (made from almost entirely water) and used a bioprinter to print objects.

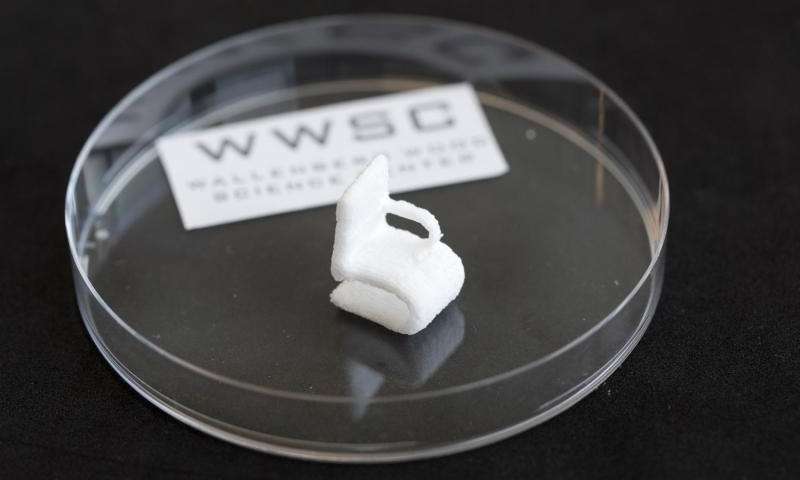

In the image above you can see a 3D printed chair, made entirely from cellulose.

It’s actually not quite as simple as that, because the wet prints must be very carefully dried to become truly solid objects.

The research team also mixed in some carbon nanotube material for fun and discovered they could 3D print electrically conductive objects in this way. A dual-extruding bioprinter, with one loaded with cellulose hydrogel and the other with carbon nanotube / cellulose hydrogel could actually print an object with an embedded electrical circuit. The research team has done this!

What does all this mean? It could be the beginning of truly recyclable 3D printing material, as cellulose is found everywhere. It’s growing in your back garden right now.

Via PhysOrg