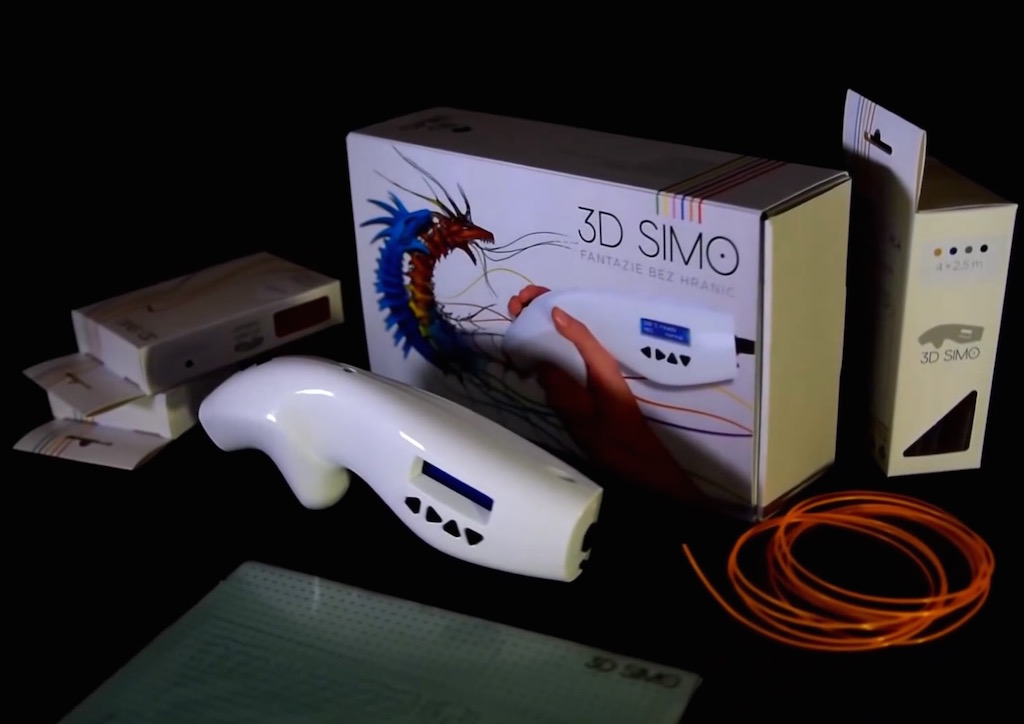

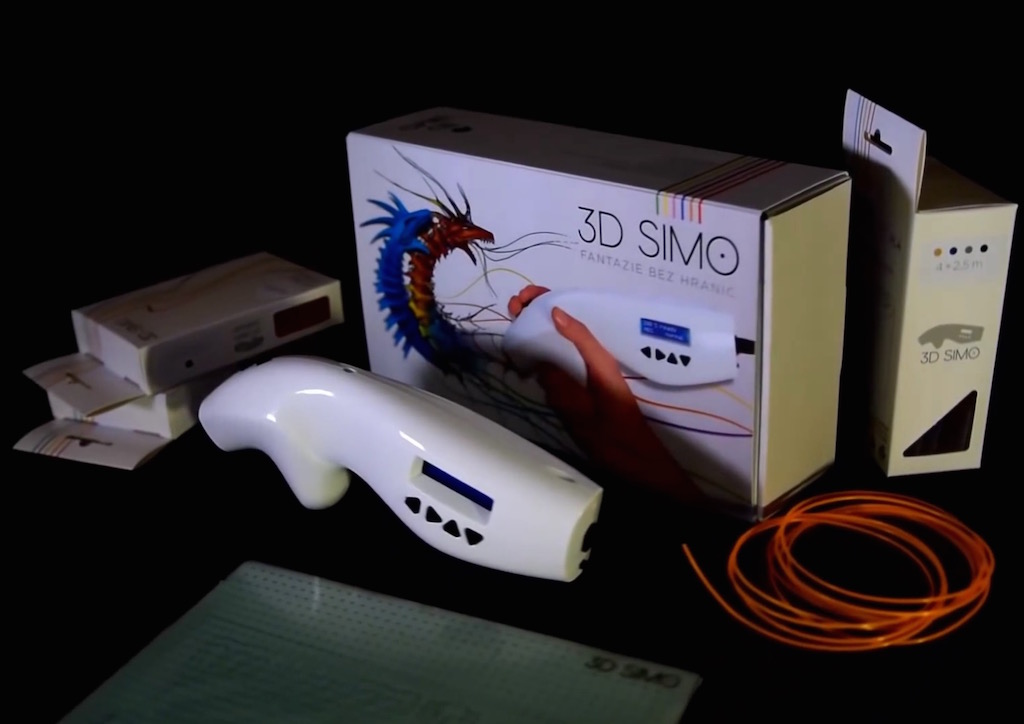

3DSimo is an unusual 3D printing pen in that it can use multiple materials. Now they’re about to launch an even smaller version.

The original 3DSimo is a 3D printing, like many others: it includes a hot end, embedded extruder and an external power supply. Basically, it’s the hot end and extruder of a 3D printer but you hold it in your hand.

Using such tools is straightforward, as you simply guide the pen in 3D to gradually create a 3D (or 2D shape) in plastic. The one issue we see with this class of devices is that larger, more complex objects would require the operator to hold the unit aloft for extended periods of time, which could become tiresome.

Here you can see how to load plastic filament into the device.

The unique feature of the 3DSimo is that it can accept multiple materials. They say you can use all these materials: ABS, PLA, PETG, HIPS, Wood, Metal, Thermochrome, Flexi, Fluorescent, Luminous, Laybrick, Brass, Bronze, Copper and Carbon fiber. For all intents, this is virtually all 3D printing materials.

How do they do this? We suspect it’s simply that they employ a steel hot end, capable of withstanding the heat required for and abrasion generated by the unusual materials, whereas other pens may use a less expensive and less capable brass nozzle.

The 3DSimo is priced at a hefty (for a 3D pen) €104 (USD$118) and is available now.

The news, however, is that there will be a 3DSimo Mini, to appear on Kickstarter in July. It seems that this device will be somewhat less capable than its big brother, but will still work with: “plastic, metal, wood, leather and foam materials”. It will include multiple tips for printing, cutting, burning and soldering, which should make it quite a useful device to have in the workshop.

The company is also holding a contest to award one 3DSimo Mini to a lucky recipient. All you need to do is provide your email on this form.

If you cannot afford a 3D printer, it’s quite possible to create interesting pieces using 3D printing pens, such as this tree. Of the many 3D printing pens now available, you might consider checking out the 3DSimo family of pens.

Via 3DSimo