MCOR recently announced something they call “HD” color 3D printing. But what kinds of 3D print color exist?

There’s a lot of confusion about color in 3D printing. Most 3D printers produce mono-color objects, which can be totally fine, as a great many applications simply require an uncolored shape.

But some of the time, printed objects should have color. Let’s define our spectrum of 3D print color:

Monocolor: This is the standard 3D printing approach, where the color is “whatever is loaded into the machine”. The color could actually be white, black, gray, neon green, transparent, milky or something else, but it’s always one and only one color.

Dual / Triple Color: This coloration approach comes from machines with dual or triple extruders, each loaded with a different color. You’ll get objects with two or three colors.

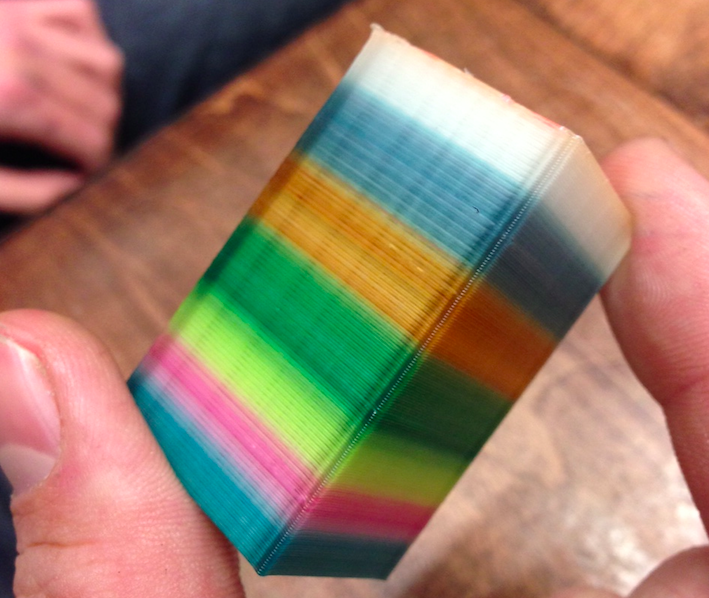

Gradient Color: This is a gradual switch from one color to another as printed layers proceed. It’s made by simply switching the filament during a print, and as the new color reaches the hot end, it mixes with the previous color to form a temporary new color before eventually flowing as the second filament’s color. Example: Black becomes progressively grey, then white as a white filament replaces a black filament.

Layered Color: This is similar to a gradient color, but is done by carefully swapping the filament and extruding waste plastic until the new color extrusion is pure. This enables very sharp, one-layer color transitions. But it takes a lot of manual effort to do so.

Spot Color: This is provided by Stratasys’ Connex3 technology, which is able to mix three colors loaded into a machine to form up to 49 color combinations. These are applied to specific portions of the 3D model as selected during print job setup. In other words, you get solid colors on certain “spots”, hence “spot color”, a term borrowed from the 2D print industry.

Full Color: For applying a complete, photographic-level texture to a 3D printed surface, you need special equipment. Currently this is only possible with two machines: The 3D Systems ProJet x60 line and the MCOR Iris, both of which are priced for industrial use.

So what’s MCOR’s “HD Color” all about? To us it’s simply a variation in quality of what we call “Full Color”. They are able to print more vibrant colors in higher resolution, likely because 3D Systems’ x60 line is limited by the granular size of their powder material, whereas MCOR’s maximum resolution is literally the thickness of a piece of paper, which is around 0.1mm thick.

When someone is talking about “color 3D printing”, you’d best ask them what type of color they mean.