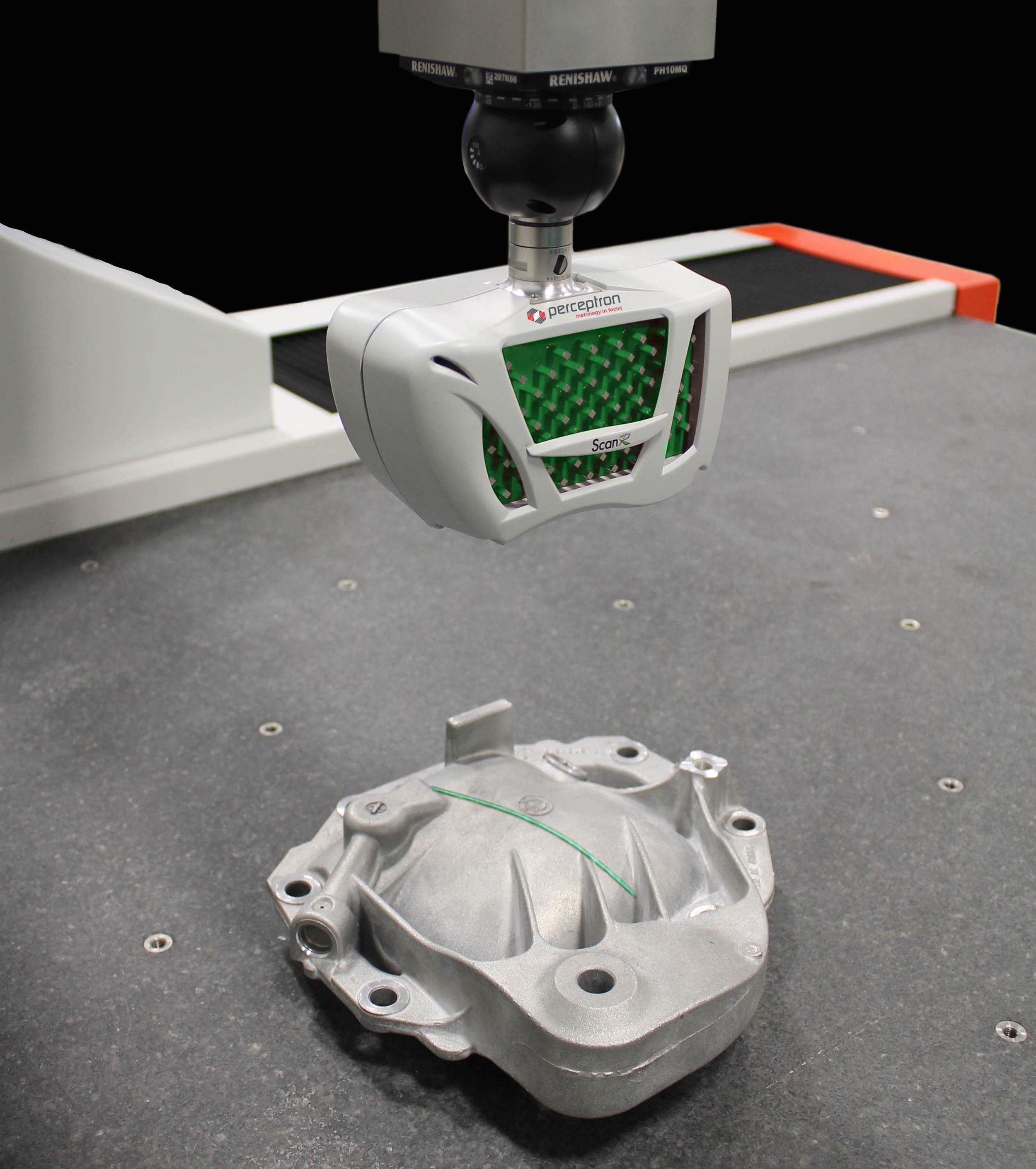

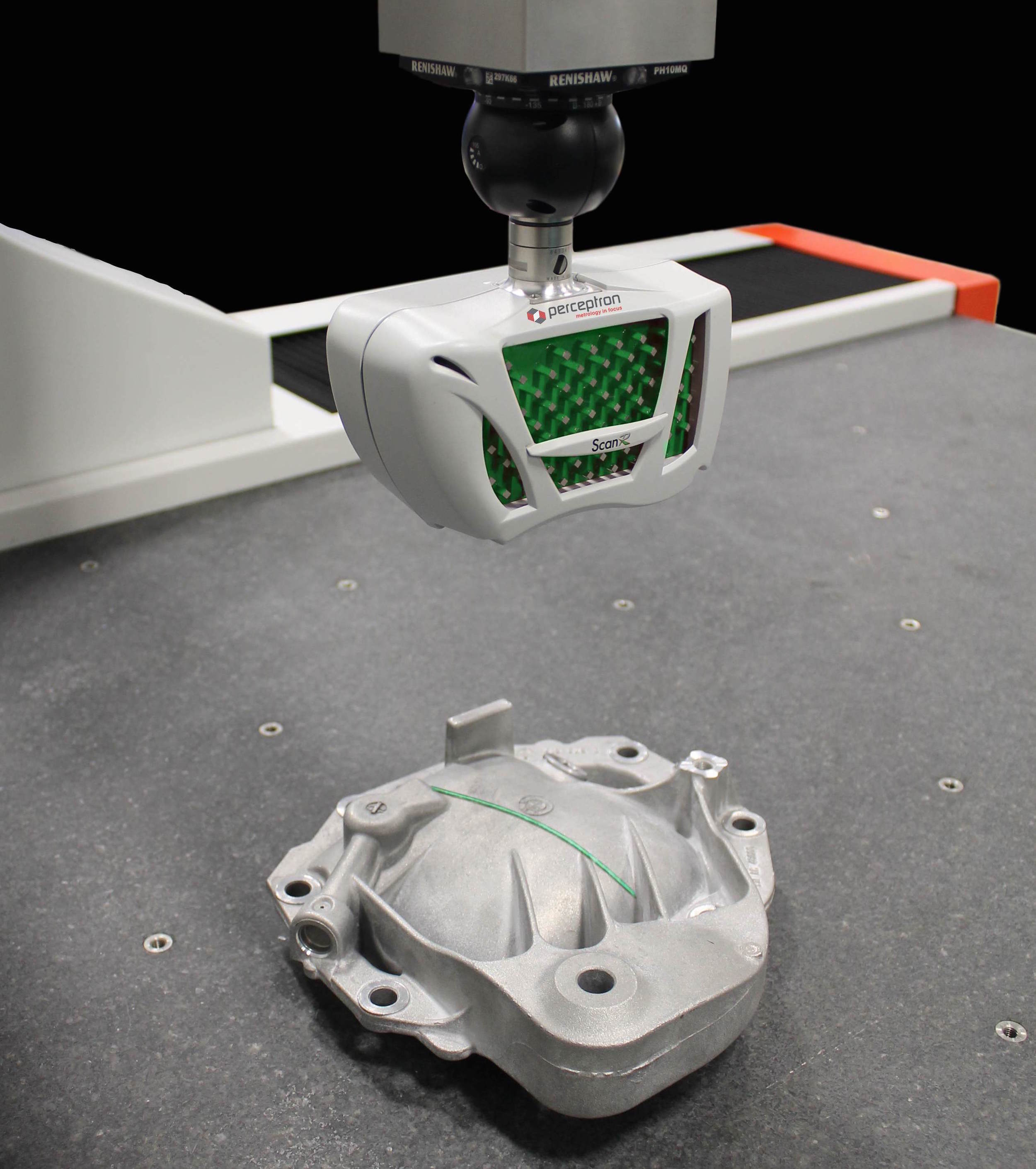

Perceptron announced a new style of 3D laser scanner that overcomes several issues.

Michigan-based Perceptron’s ScanR CMM Laser Scanner employs a green laser, the world’s first, they say.

The problem overcome by using a green laser is reflectivity. Almost all 3D scanners have severe problems attempting to 3D scan objects that are reflective or transparent, as the precisely aimed light beams are twisted by these surfaces and are thus distorted by the scanner at best and unreadable at worst.

The normal method of scanning these troublesome surfaces is to temporarily spray on a neutral powder coating to eliminate the reflectivity or transparency. Scanning can then proceed, although the surface is very slightly different in dimension, but not sufficient so to make inaccurate scans.

The problem with this approach is that it’s time consuming to apply and clean, and in some cases can even mess up object. While this is possible to do on an occasional basis, you really don’t want to be doing this on an assembly line, for example, where you have to quality check every component coming down the line.

The new ScanR from Perceptron has greatly increased dynamic range, meaning it can successfully scan a wider range of colors and reflective surfaces. They say it can now handle carbon fiber, polished or plated metal with increased accuracy, too.

So far no one has been able to develop a 3D scanner than can handle transparent objects, but that’s a very difficult problem. Meanwhile, if you require the ability to repeatedly 3D scan polished metal objects, you might want to check out the ScanR from Perceptron.

Via Perceptron