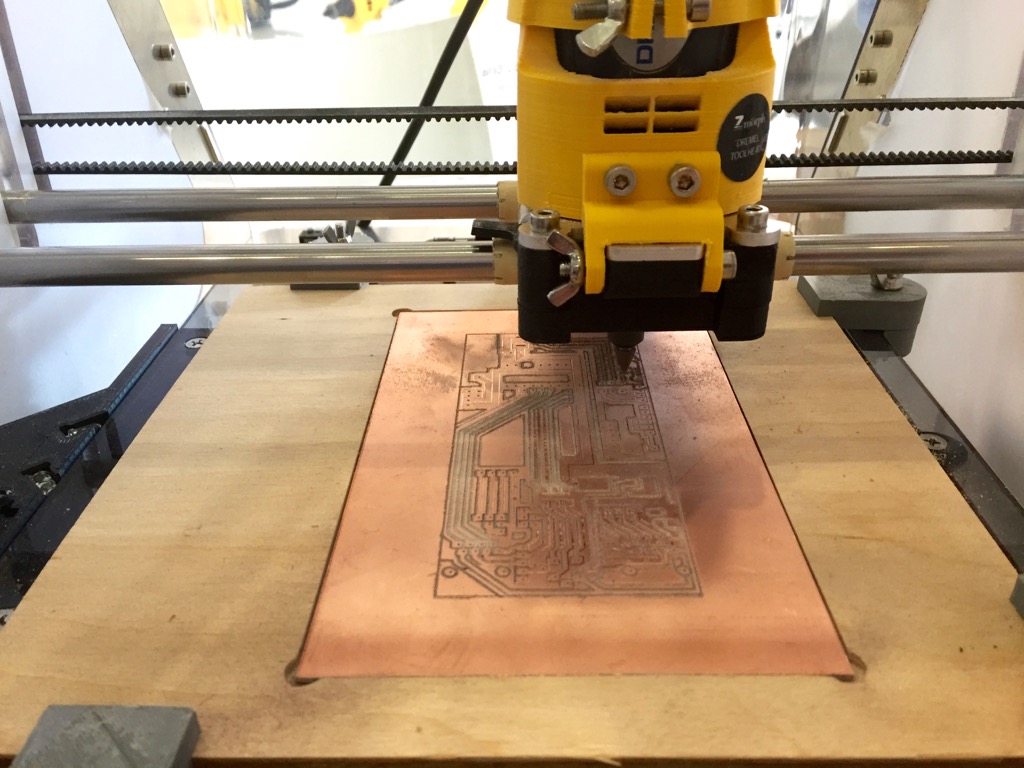

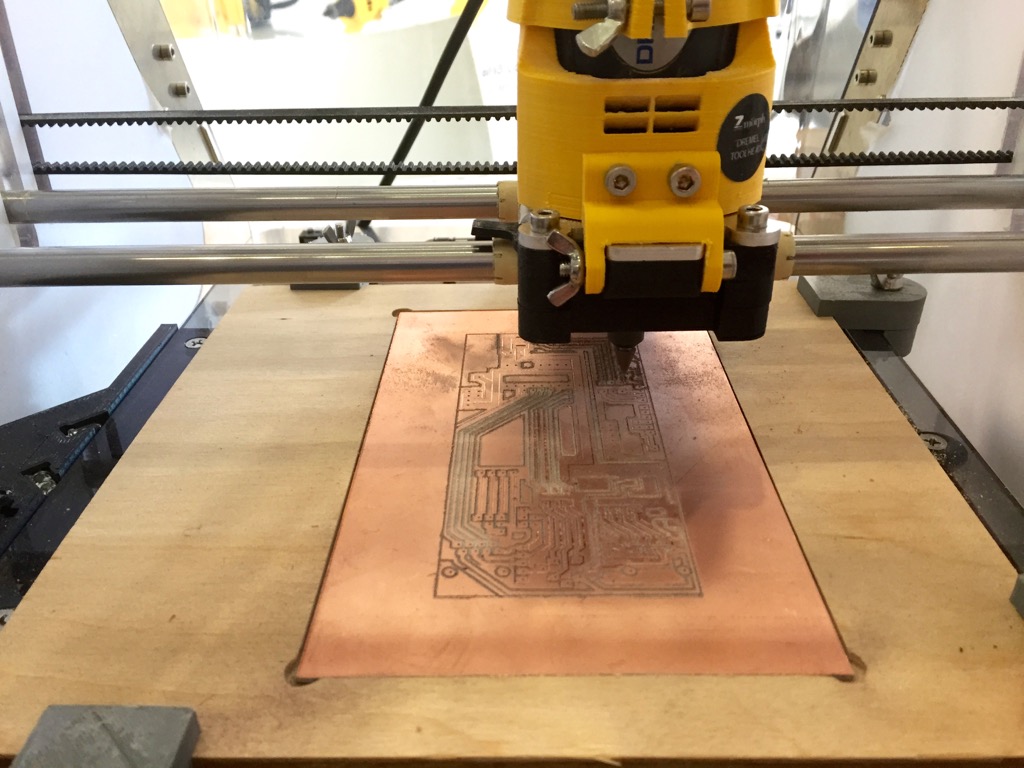

Remember ZMorph? The 3D printer that can use multiple heads for functions beyond mere 3D printing? They just added another capability: PCBs!

ZMorph’s extensive capabilities already include 3D printing, laser engraving, CNC milling, 3D scanning and paste extrusion. These all happen within the same frame by merely swapping out the functional head with another. It’s very easy to swap heads; only a couple of bolts require removal, after which the head lifts out easily.

Now they add the ability to produce custom PC boards.

It’s an adaptation of their CNC milling capability, which essentially allows you to strap a Dremel tool to the head. The innovation here is the identification of the optimum router bit for the Dremel, which is different from the bits used when CNC milling. The new bit is shaped differently and harder to more effectively work with the copper sheets used in making PC boards.

Like their previous making functions, PC board making will be self-calibrating. According to ZMorph, “The machine should understand what it needs to do and adjust accordingly.”

It’s likely ZMorph will continue adding innovative making functions in the future by adding even more options.

Via ZMorph