Sharebot is well-known for their popular plastic filament 3D printers. But did you know they’re also working on a powder-based device?

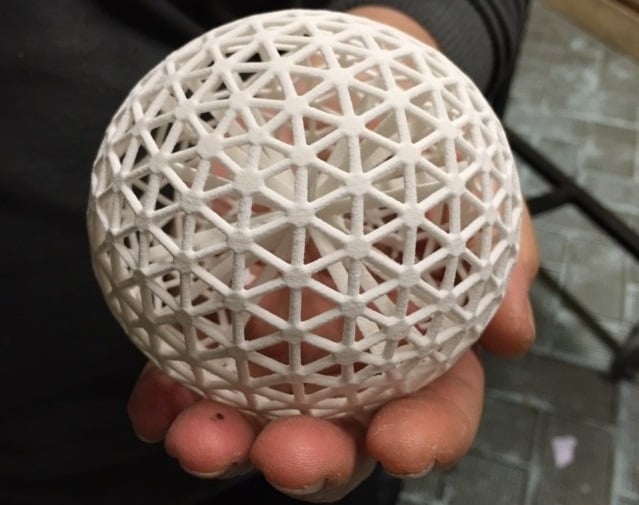

They call it “Project SnowWhite”, no doubt after the powder used in the machine. Their machine uses the SLS 3D printing process: Selective Laser Sintering. Basically, a laser traces a path over a flat bed of thermoplastic powder and fuses portions into solid form. By adding subsequent layers of powder, the machine can gradually build up a high-resolution 3D object with strong material properties.

The initial version of SnowWhite, exhibited last fall, attempted to operate in ambient temperatures, thus simplifying the machinery. However, today we learn that after several months of experimentation, they’ve relented and now SnowWhite has a heated chamber. The heat now produces better results, and SnowWhite is now capable of printing using nylon PA12 material. This should result in strong printed parts.

They’ve also changed the machine in a few other ways. First, they’ve increased the build volume to a reasonable, but not huge 100 x 100 x 130mm. They’ve also changed the mechanism that loads powder into the print chamber so that it operates significantly faster.

It’s not clear when SnowWhite becomes a real product you could purchase, but it sounds like it may be soon:

Sharebot SnowWhite is a project no more: it’s now a functioning 3D printer almost ready to be put on the market to take 3D printing to a whole new era.