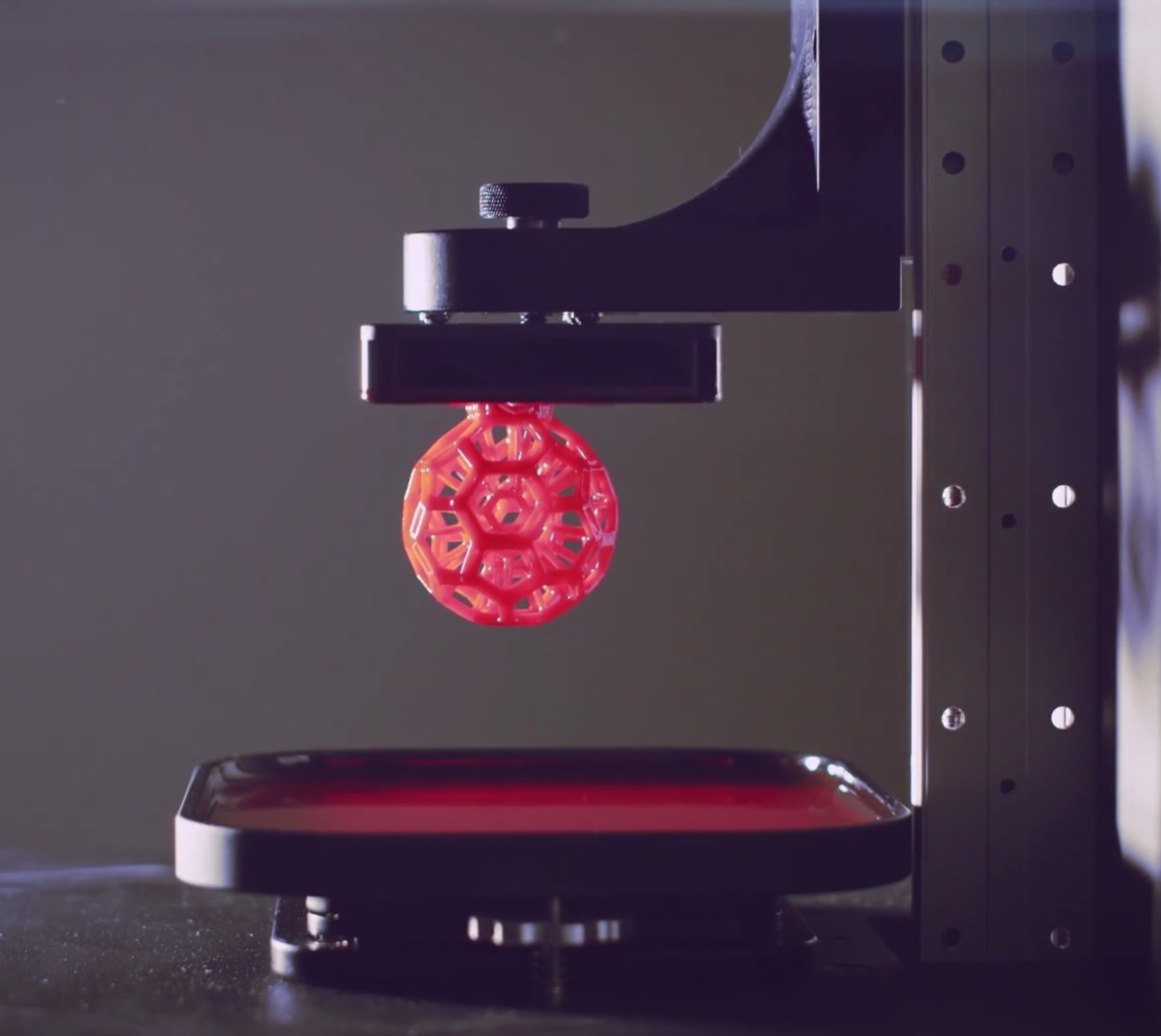

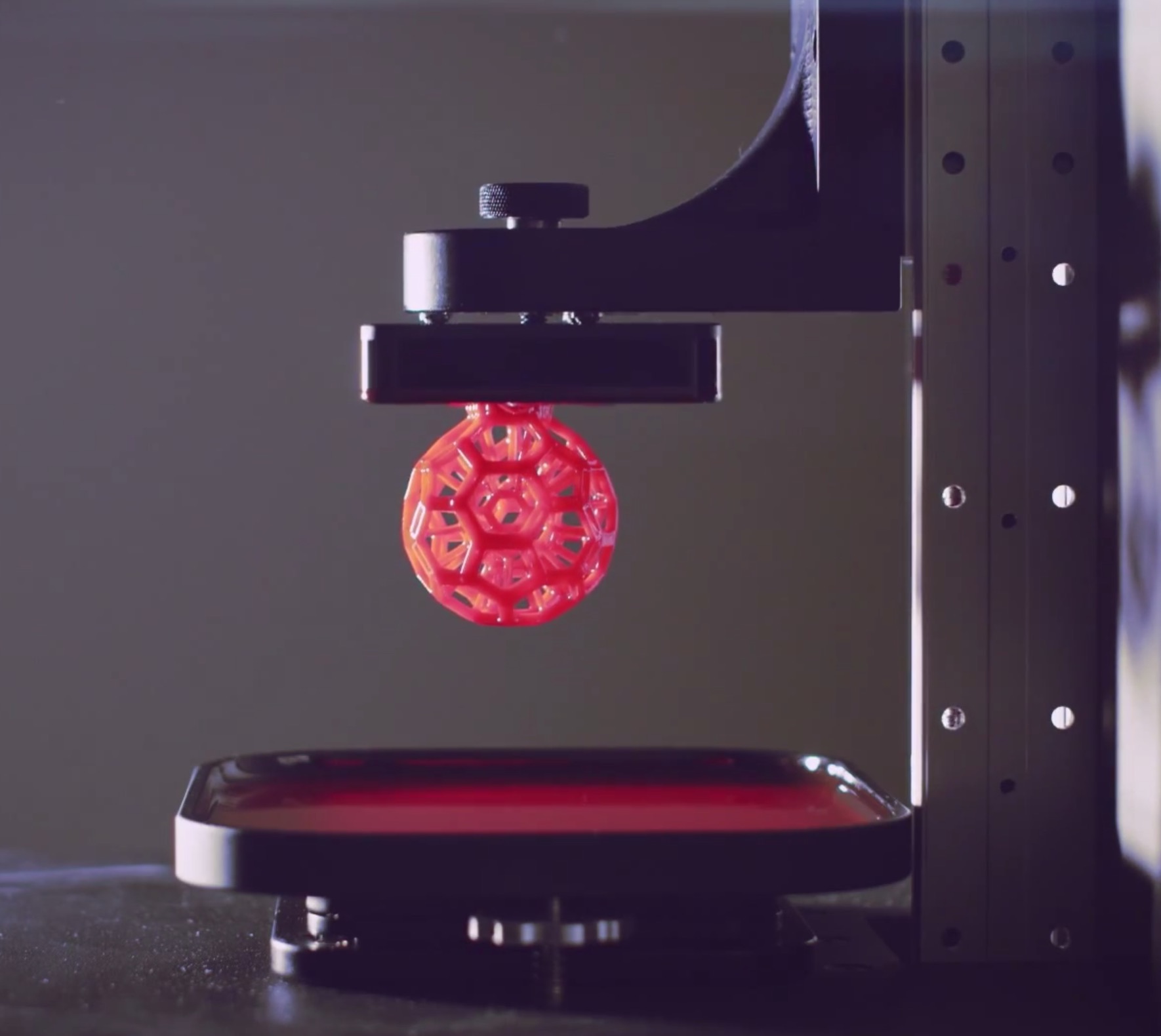

You likely saw the big announcement from Carbon3D of their revolutionary and speedy 3D printing process, but are there limitations to their approach? We think there could be.

First, a refresher on Carbon3D’s 3D printing process, with some graphics to explain what’s going on.

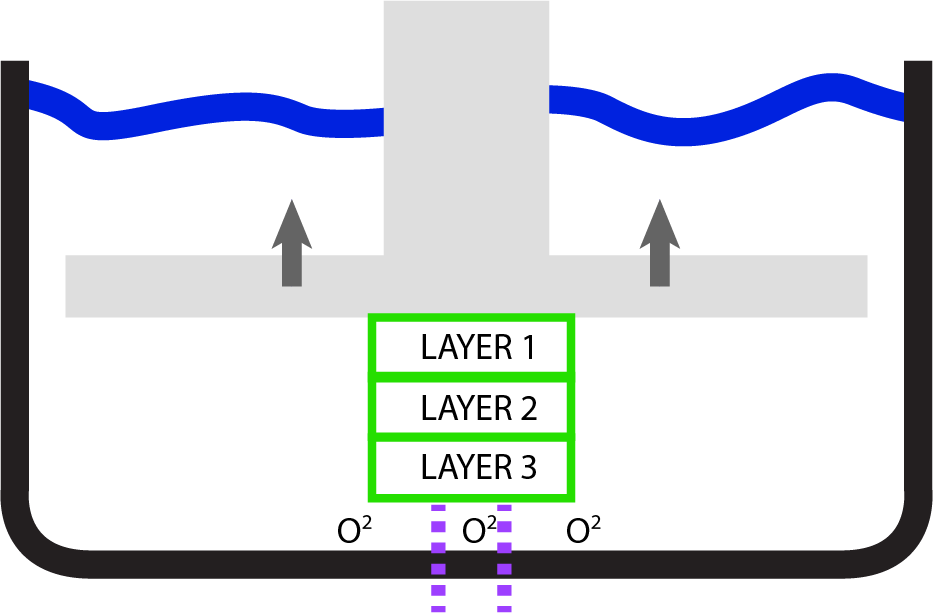

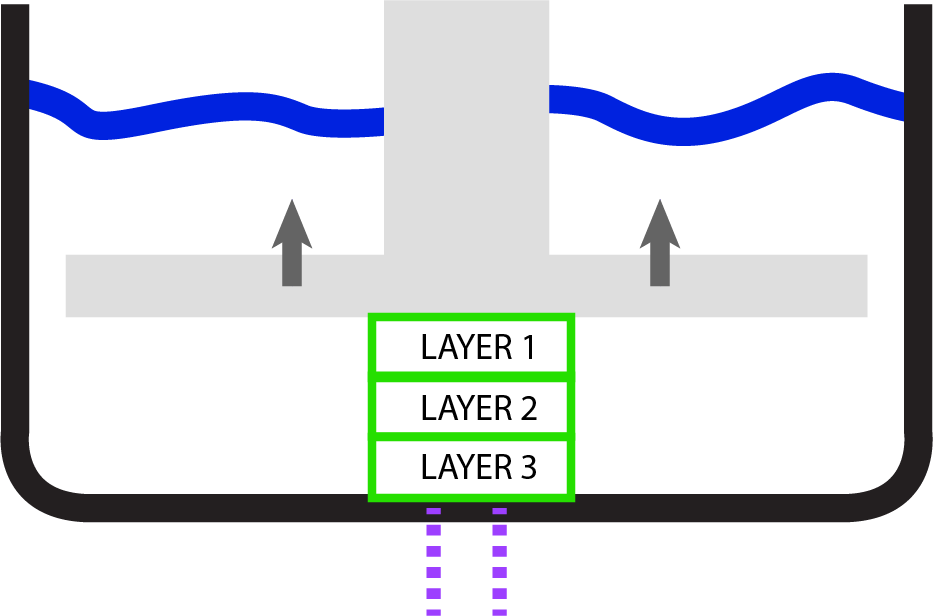

Here we see a standard UV-curable resin 3D printing process. Laser or DLP ultraviolet light (purple) shines through a transparent tank bottom to solidify selective portions of curable resin in the tank. While the solidified layer is firmly attached to the gray print bed, which gradually rises to make room for new layers, the solidified portion also binds to the tank bottom!

This requires printers using this process to slowly pull up the print surface on an angle to “peel” it off the tank bottom. This not only slows the printing process significantly, it also gradually erodes the tank because each layer’s printing rips molecules off the tank itself. As a result, you’ll eventually have to replace the tank, as it will become irregularly shaped and blur the precise UV light beams.

Carbon3D’s process is brilliant. They’ve discovered that the presence of Oxygen inhibits the solidification process. Thus, they’ve made the tank out of an oxygen-permeable material, much like contact lenses. This creates a very thin but significant layer of oxygen-soaked resin at the bottom of the tank. The UV light then harmlessly passes through the oxygenated layer and solidifies resin further up – and does NOT fuse to the tank at all. This eliminates the need for peeling and speeds up the printing process massively.

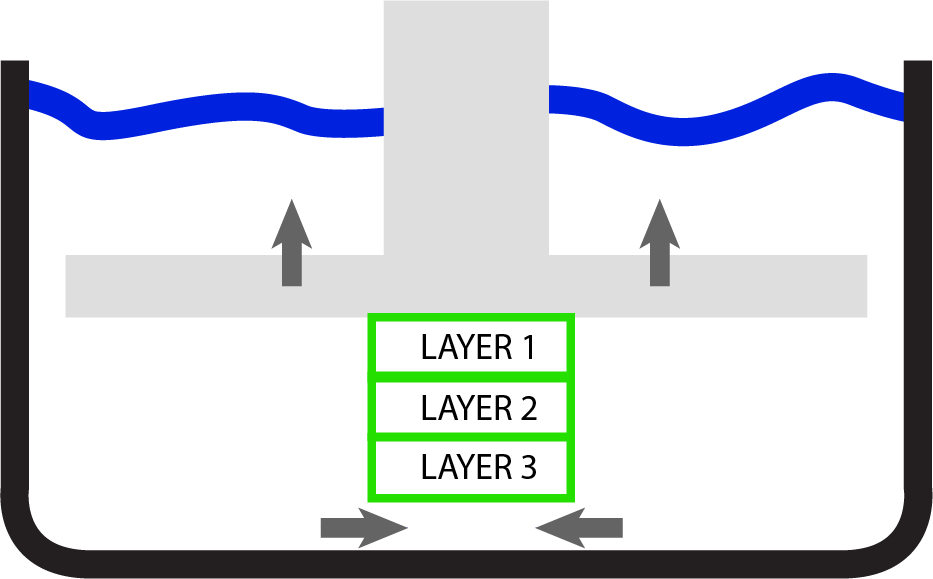

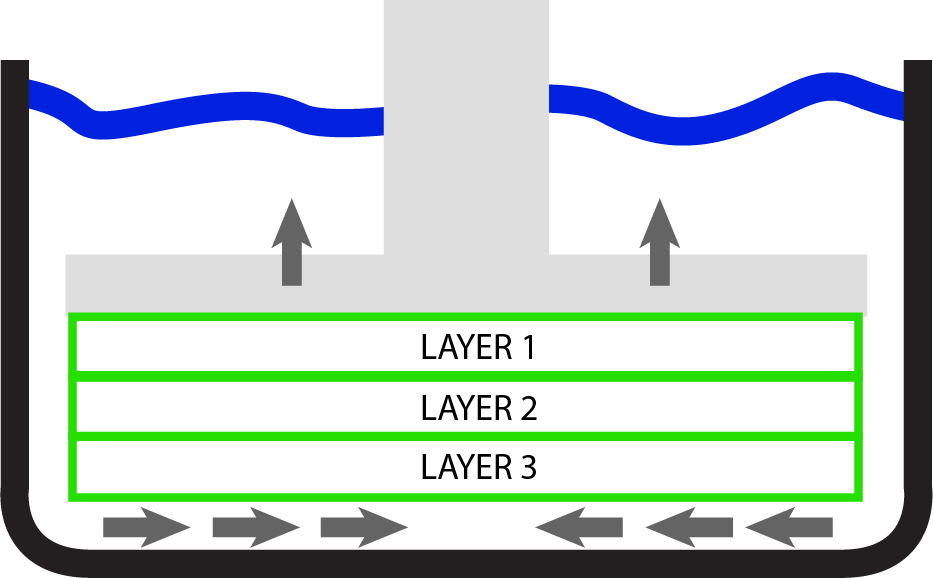

But there’s another thing going on here. When the print platform rises, resin must flow into the space under the previous layer so that it can be solidified. Here we see how that occurs.

Normally this is not an issue, but we anticipate problems when the geometry of the print is wide. The problem is that the thick, viscous resin must quickly flow all the way along the width of the layer, otherwise printing cannot occur.

While the Carbon3D process does not have any delays from peeling, they still must have delays waiting for resin flow.

Is this true? Let’s watch their now-famous time-lapse video of printing the Eiffel Tower model. Watch carefully:

Did you see it? The print speed slows dramatically at two points during the printing sequence. Now, if you look at the Eiffel Tower model, you’ll see two large bulky zones (corresponding to restaurant levels on the actual Eiffel Tower) that more than likely were the cause of the slowdown.

In other words, the Carbon3D print speed is limited by the geometry of the object, and perhaps significantly so, as the Eiffel Tower is a rather spindly object. We’d like to see how well it can print a large block, for example.

Does this mean Carbon3D’s process is not good? By no means! Their O2 improvement technique is brilliant and certainly will speed prints immensely. We’re just saying there are more opportunities here.

If we were in charge of Carbon3D, we’d have the chemistry department working very hard to develop a resin that is far less viscous. If that can be invented, the process would work even more rapidly.