In the increasingly crowded 3D printer plastic filament market, it’s harder for companies to distinguish themselves. Czech-based Eco 3D Filament may have just done that.

There are any number of companies providing 3D printer filament these days, as you can obtain reasonably-priced, decent-quality plain filament from literally dozens of suppliers in every region of the world. If you’re seeking white ABS filament with a 1.75mm diameter, it would be hard to choose a vendor with any factors beyond price comparison.

So what’s a plastic vendor to do? Eco 3D Filament has produced several interesting filaments with unusual – and useful – properties. We had a quick look at their products and thought three were of interest to the community.

First, they’ve produced a variant of ABS plastic that can be extruded at a slightly lower temperature. Depending on how your machine registers temperature, you would normally extrude ABS around 250C, but Eco’s new filament extrudes at only 230C.

This is of interest because the lower temperature means somewhat less warping. “Regular” ABS shrinks as it cools, but this filament doesn’t have to cool quite as much. It should permit printing slightly larger models, reduce the risk of prints popping off the print surface – particularly on machines without a heated print bed – and keep your extruder running with less heat and electricity.

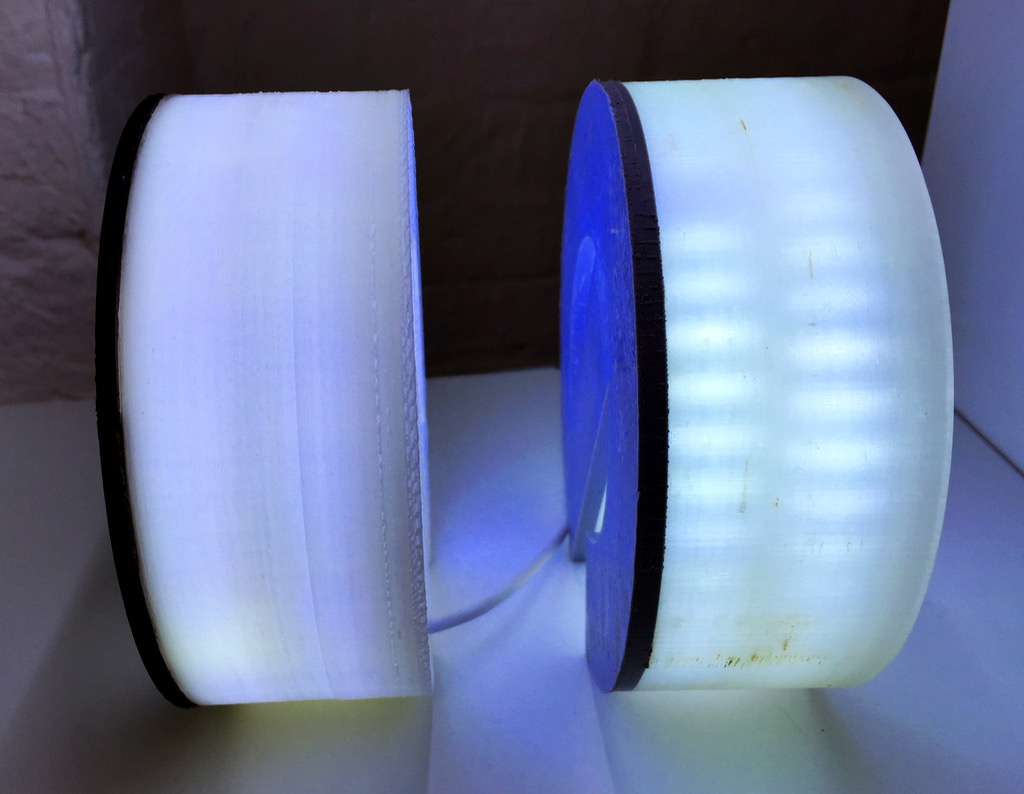

A common use case in 3D printing is to produce unusual light fixtures. Eco noticed an issue with this practice: clear(ish) filament is most often used in order to permit light to pass through the object. However, most “transparent” filaments are perhaps “too clear”: you can often literally see the embedded LED light sources.

Eco’s new filament is designed to overcome this by producing a “milky” semi-opaque finish. In the image at top you can see the results side by side. Can you guess which one is made from typical filament and which used the new Eco filament?

Finally, Eco has also produced a new type of flexible filament. We’v seen flexible filaments before, but it turns out they are often tricky to print. The main challenge is that the “rubber noodle” filament cannot be reliably pushed into a 3D printer’s hot end at speed, because it simply folds up. It does flex, after all!

Eco’s flexible filament is bendy, but not nearly as much. Thus, it can be printed at reasonable speeds. The resulting prints bendy but not “floppy level” bendy. You can vary the amount of bend by increasing or decreasing the amount of material in the flexible component. We think this filament could be of interest to those making durable parts, as its flex could enable parts printed with it to handle greater stress.

Via Eco 3D Filament